CNC turning machines play a vital role in precision manufacturing. They utilize computer-controlled technology to create complex cylindrical parts with high accuracy. This capability makes them essential across various industries. In this article, we will explore how CNC turning machines operate and their benefits for precision manufacturing.

Understanding CNC Turning Machines

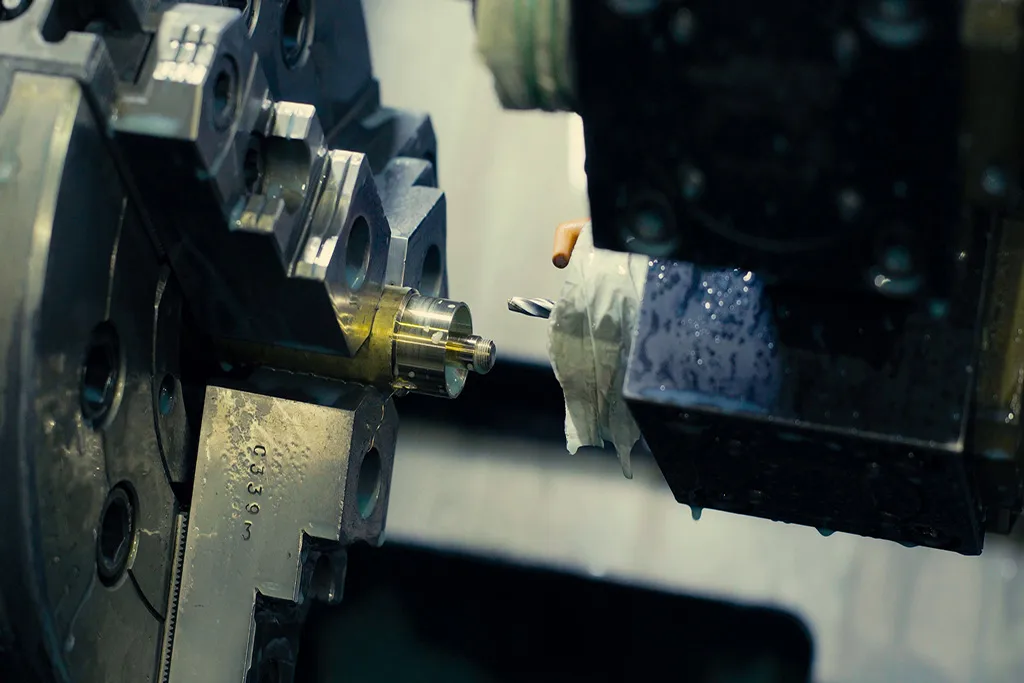

CNC stands for Computer Numerical Control. A CNC turning machine rotates the workpiece while a cutting tool shapes it. Operators input specific dimensions and designs into the machine’s software. Once programmed, the machine executes the cutting process automatically. This automation ensures consistent results and minimizes human error.

The CNC Turning Process

The CNC turning process involves several key steps. First, operators secure the material in the lathe. Next, they set the desired parameters in the computer. After that, the machine begins rotating the material. Cutting tools then remove excess material to form the desired shape.

During the turning process, operators can monitor the machine’s performance. They can make real-time adjustments if necessary. This flexibility allows for quick responses to any issues that arise, enhancing overall efficiency.

Achieving Precision

CNC turning machines excel in precision manufacturing. Several factors contribute to this accuracy:

- Tight Tolerances: CNC machines can achieve tight tolerances, often within a few microns. This level of precision is crucial for industries that demand high-quality components.

- Repeatability: Once programmed, CNC turning machines can produce identical parts consistently. This repeatability reduces waste and ensures uniformity in production.

- Advanced Tooling: Manufacturers can use various cutting tools designed for specific materials and applications. These tools enhance cutting efficiency and improve surface finishes.

Benefits of CNC Turning in Precision Manufacturing

CNC turning machines offer several advantages for precision manufacturing:

- Speed: CNC turning machines operate quickly. They can produce parts faster than traditional methods, leading to shorter lead times.

- Cost-Effectiveness: Although the initial investment in CNC technology can be high, the long-term savings are significant. Automated processes reduce labor costs and minimize material waste.

- Complex Designs: CNC turning machines can create intricate shapes and designs that are difficult or impossible to achieve manually. This capability expands the possibilities for product development.

- Material Versatility: CNC Machine Tools can work with various materials, including metals, plastics, and composites. This versatility allows manufacturers to select the best material for each application.

Applications of CNC Turning Machines

CNC turning machines find applications in numerous industries. Here are some key examples:

- Automotive Industry: Manufacturers use CNC turning for engine components, shafts, and fittings. The precision required for these parts is critical for performance and safety.

- Aerospace Industry: Aerospace components often demand the highest precision. CNC turning machines produce critical parts like turbine blades and landing gear components.

- Medical Devices: CNC turning machines manufacture surgical instruments, implants, and other medical components. The accuracy and reliability of these parts are paramount.

- Electronics: In the electronics sector, CNC turning machines create housings, connectors, and other intricate components that require precision.

Future Trends in CNC Turning

As technology advances,CNC Machine Tools continue to evolve. New developments include:

- Smart Manufacturing: Integration with IoT (Internet of Things) technology allows machines to communicate and optimize performance in real time. This capability enhances efficiency and reduces downtime.

- Adaptive Machining: Future CNC Machine Tools may utilize AI algorithms to adjust cutting parameters automatically. This adaptation can improve precision and efficiency even further.

- Sustainable Practices: Manufacturers are increasingly focusing on sustainability. CNC turning can contribute by minimizing waste and using energy-efficient processes.

Conclusion

In conclusion, CNC turning machines are essential for precision manufacturing. Their ability to produce high-quality components quickly and consistently makes them invaluable across various industries. By utilizing advanced technology and skilled operators, manufacturers can achieve unmatched precision and efficiency. As CNC technology continues to advance, the potential for innovation in precision manufacturing will only grow. Embracing CNC turning will allow businesses to remain competitive and meet the demands of the modern marketplace.