Laser cutting is a technology that uses a laser to cut materials. It has become popular across various industries due to its precision and efficiency. This article explores the basics of laser cutting, its applications, and its advantages.

The Basics of Laser Cutting

Laser cutting involves directing a high-powered laser beam onto a material’s surface. The laser heats the material to a point where it melts or vaporizes. This process creates a clean and precise cut. Operators can adjust the laser’s intensity and speed based on the material’s thickness and type. Common materials for laser cutting include metals, plastics, wood, and textiles.

How Does Laser Cutting Work?

The laser cutting process begins with a computer-aided design (CAD) file. This file outlines the desired design. Next, the laser cutter uses this file to guide the laser beam. As the laser moves, it cuts through the material, leaving a smooth edge. This method minimizes waste, as it cuts exactly where needed.

Moreover, laser cutting can achieve intricate designs that other cutting methods cannot. For example, it can create detailed patterns in wood or complex shapes in metal. This capability makes laser cutting ideal for custom projects.

Applications of Laser Cutting

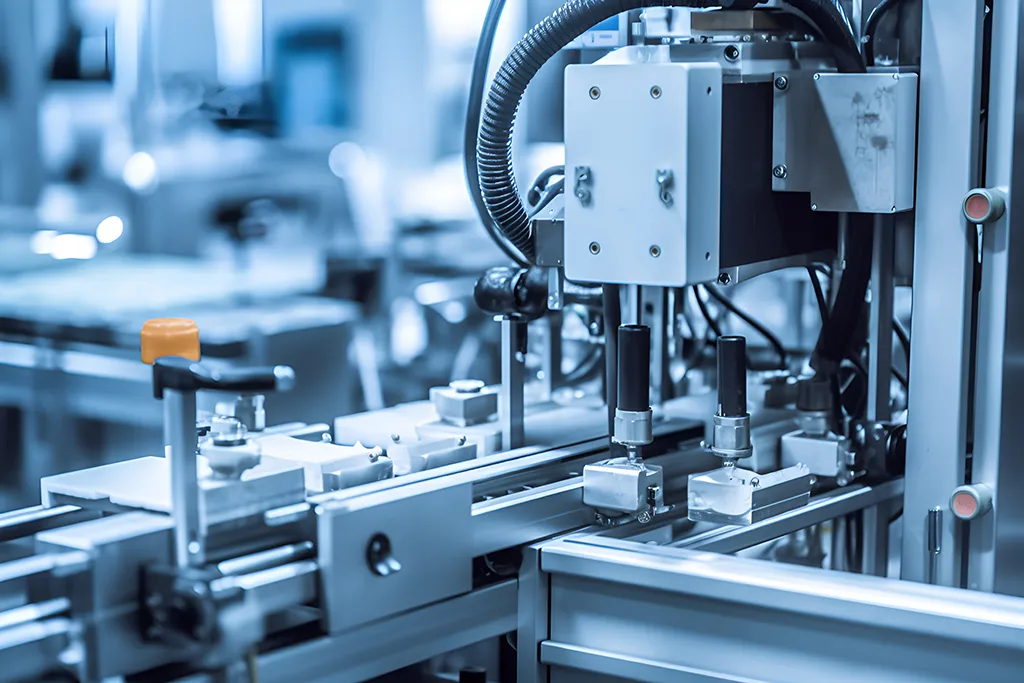

Laser cutting is widely used in various industries. In manufacturing, it helps create parts for machines, vehicles, and electronics. For instance, the automotive industry relies on laser cutting for precise metal parts. Similarly, the aerospace sector uses laser-cut components for aircraft.

In the fashion industry, designers use laser cutting to create unique fabric patterns. This technique allows for creativity and customization. Additionally, laser cutting finds applications in signage, creating eye-catching signs and displays.

Advantages of Laser Cutting

One significant advantage of laser cutting is its precision. The laser beam can cut materials to very tight tolerances. This accuracy reduces the need for additional finishing processes. Consequently, it saves time and resources.

Another benefit is the versatility of materials. Laser cutting works with various materials, from thin fabrics to thick metals. This adaptability makes it suitable for many applications.

Furthermore, laser cutting is efficient. The process is fast, which increases productivity. As a result, businesses can complete projects more quickly. Additionally, the minimal waste generated during cutting contributes to cost savings.

Environmental Considerations

Many businesses are becoming more environmentally conscious. Laser cutting is a greener option compared to traditional cutting methods. It produces less waste and uses less energy. Moreover, some laser cutting machines have features that enhance energy efficiency.

Businesses can also recycle the waste material generated during laser cutting. This approach further reduces environmental impact. By choosing laser cutting, companies can promote sustainability while maintaining high-quality production.

Conclusion

In summary, laser cutting is a powerful technology that offers numerous benefits. Its precision, versatility, and efficiency make it a preferred choice in many industries. Whether in manufacturing, fashion, or signage, laser cutting enhances creativity and productivity. As businesses continue to prioritize sustainability, laser cutting will likely play an even more significant role in the future.

By understanding the basics and advantages of laser cutting, businesses can make informed decisions. This knowledge allows them to leverage this technology for their projects effectively. In turn, they can achieve better results while minimizing their environmental footprint.