In manufacturing and fabrication, choosing the right cutting method is crucial. Two popular techniques are laser cutting and blade cutting. Each method has its own advantages and disadvantages. In this article, we will explore the differences between laser cutting and blade cutting, helping you determine which method is best for your needs.

Precision and Accuracy

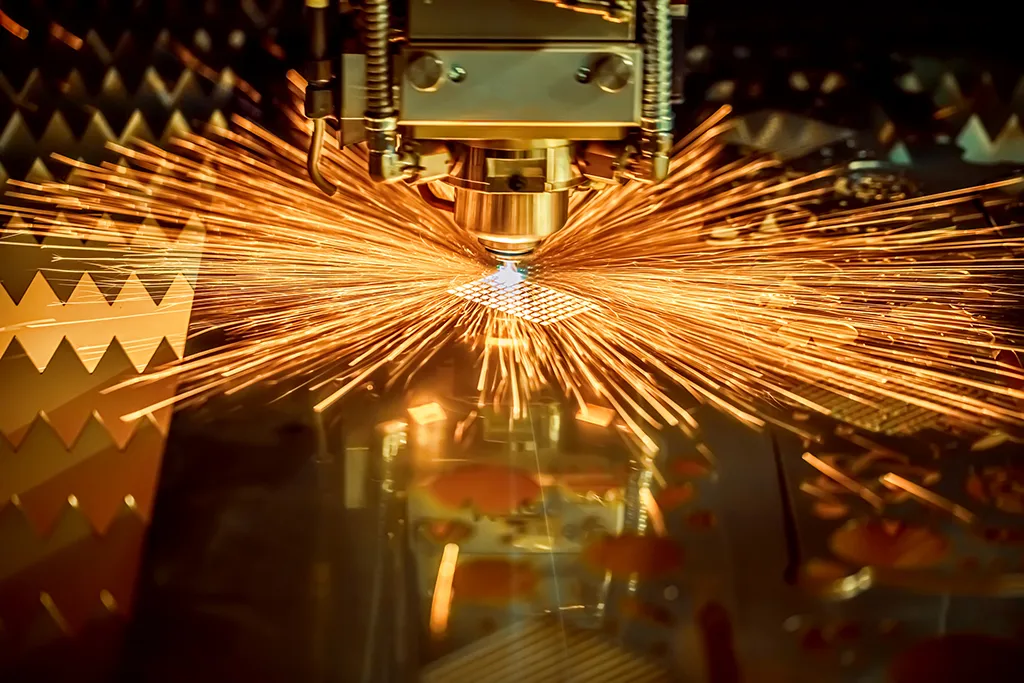

One of the most significant differences between laser cutting and blade cutting is precision. Laser cutting uses a highly focused beam of light to cut through materials. This process allows for incredibly precise cuts, often with tolerances of a fraction of a millimeter. The clean edges produced by laser cutting require minimal finishing, making it ideal for intricate designs and complex shapes.

On the other hand, blade cutting relies on mechanical blades to slice through materials. While blade cutting can achieve good accuracy, it may not match the precision of laser cutting. The edges produced by blade cutting can be rougher, necessitating additional finishing processes. This difference is particularly noticeable when working with detailed or intricate designs.

Material Compatibility

Another crucial distinction lies in material compatibility. Laser cutting is versatile and can cut through a wide range of materials, including metals, plastics, wood, and textiles. It excels in cutting thin sheets of material and can handle complex shapes with ease. However, its effectiveness may vary depending on the material thickness and type.

Conversely, blade cutting is typically limited to softer materials. It works well with wood, cardboard, and certain plastics but struggles with harder materials like metals. Additionally, thicker materials may present challenges for blade cutting, as the blades may not penetrate effectively. As a result, laser cutting often has a broader range of applications across different industries.

Speed and Efficiency

Speed is another factor to consider when comparing these two cutting methods. Laser cutting can process materials quickly, especially for complex shapes. The ability to cut multiple parts simultaneously makes it highly efficient for high-volume production runs. Additionally, laser cutting machines can operate continuously, minimizing downtime.

In contrast, blade cutting can be slower, particularly for intricate designs. The mechanical nature of blade cutting means that it requires more time to complete cuts, especially when working with thicker materials. Moreover, blade replacement and maintenance can lead to interruptions in production. Consequently, laser cutting is often preferred for applications requiring speed and efficiency.

Cost Considerations

When evaluating laser cutting versus blade cutting, cost is a crucial factor. Laser cutting machines typically involve higher initial investment costs. They require specialized equipment, technology, and maintenance. However, the long-term savings from reduced material waste and faster production times can offset these initial costs.

Blade cutting machines, on the other hand, are generally more affordable. The equipment is simpler and often easier to maintain. However, the potential need for additional finishing processes and slower production speeds can increase overall costs over time. Businesses should weigh these factors carefully when choosing a cutting method.

Versatility and Applications

Laser cutting is highly versatile, making it suitable for various applications. Industries such as aerospace, automotive, and fashion utilize laser cutting for its precision and adaptability. It is especially beneficial for custom designs and prototypes.

Blade cutting is common in woodworking and packaging industries. It excels in producing simple shapes and straightforward cuts. However, its limitations in handling intricate designs may restrict its applications compared to laser cutting.

Conclusion

In summary, laser cutting and blade cutting are distinct methods with unique advantages and disadvantages. Laser cutting offers unparalleled precision, versatility, and speed, making it ideal for complex designs and a wide range of materials. Blade cutting, while more affordable, is limited in terms of material compatibility and precision.

When deciding between laser cutting and blade cutting, consider your specific needs. Evaluate factors such as material type, desired precision, production speed, and budget. Understanding these differences will help you make an informed choice that best suits your manufacturing requirements. As technology continues to advance, both methods will play important roles in various industries, but laser cutting remains a standout choice for precision and versatility.