As plastic 3D printing gains popularity, questions about its environmental impact arise. Many see it as a revolutionary technology, but is it eco-friendly? In this article, we explore how plastic 3D printing technology affects the environment, covering its benefits, challenges, and sustainability innovations.

1. Reduced Material Waste

One of the main benefits of 3D printing is its material efficiency. Unlike traditional manufacturing, which often cuts away material, 3D printing uses an “additive” process. It builds objects layer by layer, only using the amount of material needed. This approach reduces waste, which can help conserve resources and lower manufacturing costs.

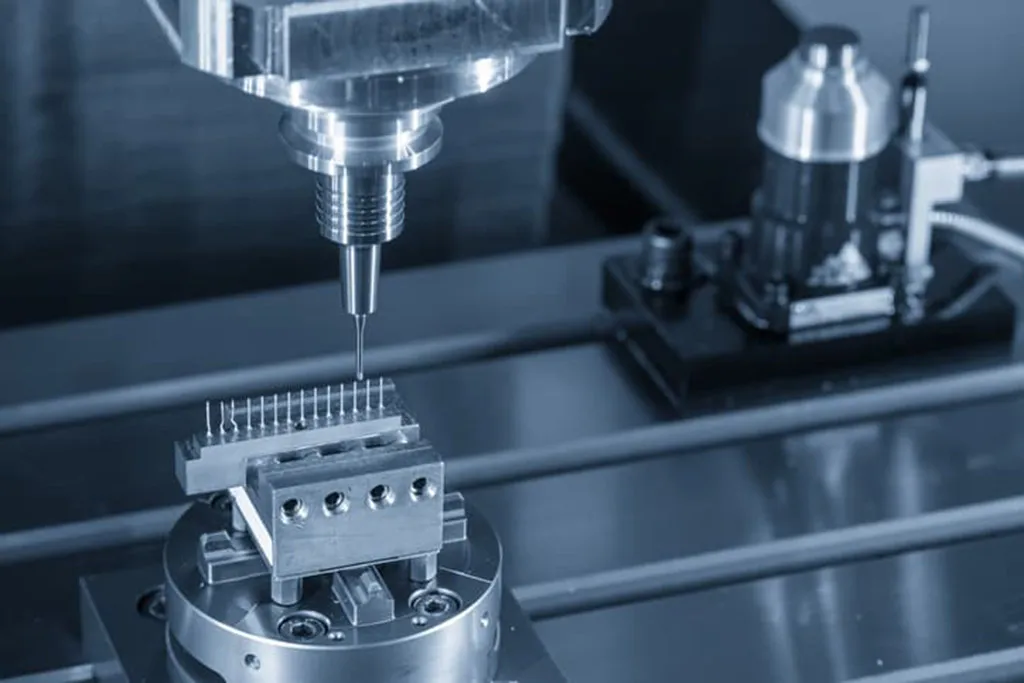

For industries needing rapid prototypes or custom designs, this efficiency can make a significant environmental difference. Fields like automotive and aerospace rely on 3D printing to reduce material waste while still producing high-quality parts.

2. Biodegradable and Recycled Materials

Many 3D printers now use biodegradable and recycled materials, helping reduce environmental impact. PLA, a popular 3D printing plastic, is biodegradable and sourced from renewable resources like cornstarch. This makes it a more eco-friendly choice than petroleum-based plastics.

Additionally, some companies are developing filaments from recycled plastics, such as used PET bottles. By reusing waste materials, these recycled filaments promote a circular economy, which reduces the demand for new plastic production.

3. Lower Energy Use in Production

3D printing often requires less energy than traditional manufacturing, particularly for small production runs. In traditional methods, energy goes into powering heavy machinery, transportation, and material processing. But with 3D printing, companies can create parts and products on-demand, reducing both energy use and waste.

Yet, it’s worth noting that some 3D printers, especially industrial models, consume significant power. Still, for rapid prototyping and small-scale production, 3D printing is generally more energy-efficient. Some companies are also adopting renewable energy sources to further lower their carbon footprint.

4. On-Demand and Localized Production

One advantage of 3D printing is that it enables on-demand and localized production. Rather than shipping products from centralized factories, businesses can print parts closer to where they’re needed. This reduces transportation emissions and helps lower overall carbon impact.

For industries like healthcare, where custom parts are essential, this capability is invaluable. Hospitals can print medical devices or surgical tools on-site, reducing shipping needs and supporting sustainability goals.

5. Plastic Waste and Recycling Challenges

Despite its benefits, plastic 3D printing has challenges, especially with waste. Failed prints, test models, and obsolete parts contribute to plastic waste. Not all 3D-printed plastics are biodegradable, and some, like ABS, degrade slowly, adding to landfill waste.

Recycling 3D-printed plastic is also complicated. While PLA is biodegradable, it requires industrial composting. Recycling facilities that handle 3D printing plastics are limited, though some companies have begun developing specialized recycling systems. For example, some machines can grind used plastic parts into new filament, creating a closed-loop system to reduce waste.

6. Eco-Friendly Material Innovations

The demand for sustainable materials is leading to new 3D printing options. Today, companies are producing filaments made from renewable resources like algae and hemp. These eco-friendly materials have a smaller carbon footprint than traditional plastics and are often biodegradable.

Innovations also include recycled filaments and composite materials that mix bioplastics with waste materials, such as wood or bamboo. These developments make it possible to create durable, eco-friendly parts that support both functionality and sustainability.

7. Energy-Efficient Practices for Greener Printing

Adopting energy-efficient practices can also make 3D plastic printing greener. Choosing low-energy printers, minimizing print times, and using eco-friendly settings all help reduce environmental impact. Some companies have optimized their 3D printing workflows to ensure that they’re using minimal energy and producing less waste.

Additionally, designing parts for 3D printing can make them more sustainable. By creating lightweight, efficient designs, companies use less plastic and still produce durable, functional parts. This approach reduces both material use and energy consumption, maximizing the sustainability of 3D plastic printing.

Conclusion

So, is 3D plastic printing environmentally friendly? It depends on the materials, processes, and practices used. 3D printing offers advantages, like reduced waste and localized production, but energy use and plastic waste remain concerns. However, with eco-friendly materials, recycling innovations, and energy-efficient practices, 3D printing can move closer to true sustainability. As the technology evolves, it has the potential to become a vital tool for environmentally conscious manufacturing.