CNC machining is to precisely control the machine tool through pre-written CNC programs, thereby achieving precision machining of various materials. In the CNC machining process, the selection and use of tools are crucial. So, how many different types of tools are there in CNC machining?

1. Milling cutter

Milling cutter plays a vital role in CNC machining. It is mainly used for milling shapes such as planes, curves and contours. According to different shapes and uses, milling cutters are further subdivided into flat head milling cutters, ball head milling cutters, keyway milling cutters and angle milling cutters. The design of flat head milling cutters makes it particularly suitable for machining planes and simple contour shapes. The ball head milling cutter, due to its unique shape, can easily cope with the machining needs of curved surfaces and arc structures.

2. Drill bit

It is mainly used for drilling operations in CNC machining. The drill bit is one of the indispensable tools in CNC processing. Common types of drill bits include twist drills, flat drills and center drills. Twist drills have become the first choice for processing various hole diameters due to their wide application.

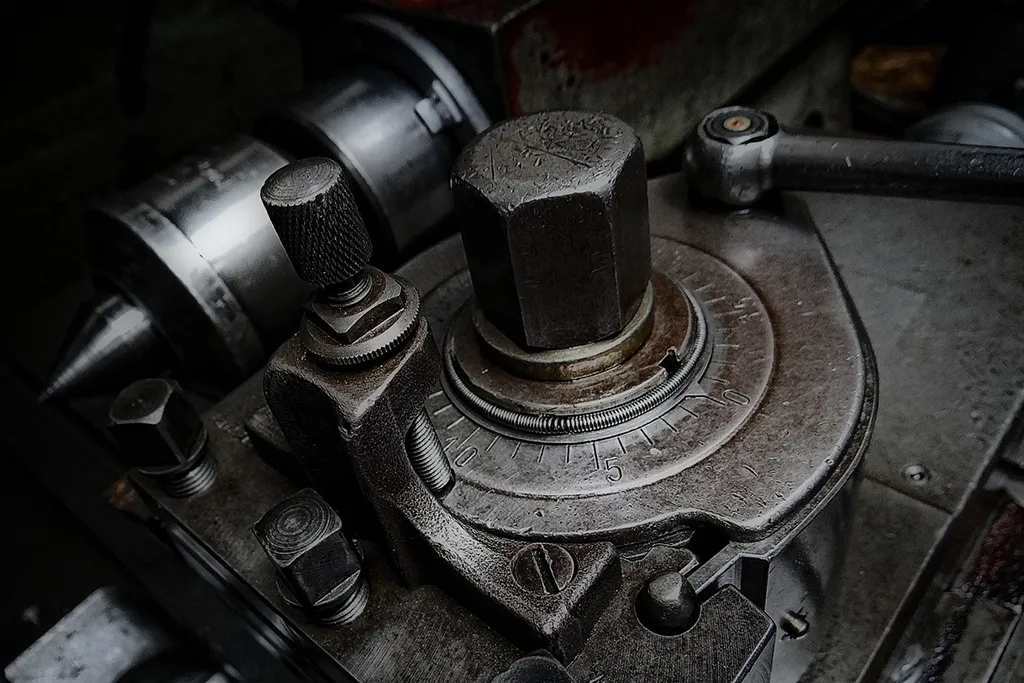

3. Turning tool

Turning tools also play an important role in CNC processing. Turning tools are mainly used for turning processing, and can process various shapes such as external circles, internal holes, and end faces.

The blade of the external turning tool is arc-shaped, which can fit closely to the surface of the cylinder for cutting.

The blade of the internal hole turning tool is thinner and longer, and can cut deep into the hole.

The blade of the cutting turning tool is sharp and strong, and can quickly cut the workpiece without affecting its overall structure.

4. Boring tool

Boring tools are mainly used for boring processing. They can ensure that the dimensional accuracy and surface finish of the hole reach a very high level. Types of boring tools include standard boring tools and floating boring tools. Standard boring tools are suitable for processing simple hole diameters, while floating boring tools can automatically adjust the position of the tool during processing to adapt to slight changes in the hole, thereby ensuring that the processed holes have extremely high precision and finish.

5. Other tools

In addition, there are many other types of tools in CNC processing, such as thread tools, saw blade milling cutters and reamers. Thread tools are mainly used for processing threads, saw blade milling cutters are used for sawing materials, and reamers are used for reamer processing to improve the dimensional accuracy and surface finish of holes. These tools play an irreplaceable role in CNC processing.

In short, there are many kinds of tools in CNC machining, and different tools have their own unique structure and design, which are suitable for different machining tasks. In the actual machining process, we need to choose the appropriate tool according to the specific situation to ensure machining efficiency and product quality.