Introduction

High precision mechanical machining solutions are essential for modern industries where exactness and performance are paramount. From aerospace to medical and automotive sectors, companies increasingly depend on precision machining to produce parts with tight tolerances and intricate details. With technological advancements and specialized equipment, precision machining has reshaped the manufacturing landscape by ensuring quality, reliability, and faster production. Here, we explore the benefits of high precision machining and why *rapidefficient* stands out as a leader in the field.

What is High Precision Mechanical Machining?

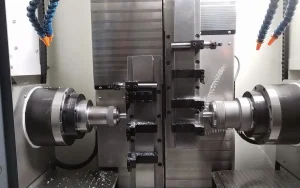

High precision mechanical machining involves using advanced equipment and technology to manufacture parts that meet strict tolerances and exacting specifications. Unlike standard machining, high precision machining focuses on producing components with near-perfect accuracy, making it ideal for parts that require consistent quality and close dimensional conformity. The process often involves CNC (Computer Numerical Control) machines, which follow precise instructions to cut, drill, and shape components accurately and efficiently.

Advantages of High Precision Mechanical Machining Solutions

- Unmatched Accuracy

High precision machining offers exact control over each manufacturing step, producing parts that fit seamlessly into larger assemblies. With tolerances that can be within microns, precision machining is essential for applications where accuracy cannot be compromised.

2. Improved Efficiency and Consistency

Precision machining reduces the need for rework by achieving consistent results in each production run. Automated CNC systems perform each step accurately, ensuring parts are uniform, even in high-volume production. This efficiency makes precision machining particularly valuable for companies aiming to streamline production without sacrificing quality.

3. Versatility Across Materials

High precision machining can accommodate a wide range of materials, including metals, plastics, and composites. This versatility allows manufacturers to create custom solutions tailored to specific project requirements, whether for durable metal components or lightweight plastic parts.

4. Enhanced Product Lifespan

The exactness of precision machining results in parts that wear less over time. Components manufactured with high precision are more durable and reliable, which is especially important in industries where product lifespan directly impacts performance and safety, such as aerospace and medical device manufacturing.

Rapidefficient: A Leader in High Precision Mechanical Machining

When choosing a provider for high precision mechanical machining, it’s essential to partner with a company that combines expertise, advanced technology, and a commitment to quality. Rapidefficient is a top choice in the CNC machining industry, offering clients several advantages:

1. Cutting-Edge CNC Machinery

Rapidefficient utilizes state-of-the-art CNC equipment capable of achieving ultra-tight tolerances and handling complex designs. Their machines are designed to work with a wide range of materials, ensuring that every project meets the exact standards required.

2. Experienced Machinists and Engineers

The team at rapidefficient brings extensive experience and technical expertise to each project. They understand the nuances of high precision machining, from programming to final inspection, ensuring that every component meets clients’ expectations.

3. Stringent Quality Control

Quality is a top priority for rapidefficient. Each part undergoes a comprehensive inspection process to ensure it aligns with specifications. This focus on quality minimizes errors and provides customers with reliable, high-performance parts.

4. Timely and Cost-Effective Solutions

With optimized workflows and advanced automation, rapidefficient offers fast turnaround times without compromising precision. Their ability to complete projects quickly and accurately can help clients reduce costs and meet tight production deadlines.

Applications of High Precision Mechanical Machining

Precision machining finds applications in numerous fields. Here are a few examples:

Aerospace: High precision components are vital for aircraft and spacecraft, where accuracy impacts safety and performance.

Medical Devices: In the medical industry, precision is essential for devices and implants that must meet stringent quality standards.

Automotive: Precision machining enhances the reliability of automotive parts, contributing to vehicle performance and longevity.

Electronics: For electronics, precision machining produces small, intricate components essential for devices like smartphones and computers.

Tips for Optimizing High Precision Machining Projects

For businesses aiming to maximize the benefits of high precision machining, the following tips can enhance project outcomes:

1. Define Specifications Clearly

Communicate material needs, tolerances, and any other project requirements with your machining provider. Clear specifications help avoid misunderstandings and ensure the final product meets expectations.

2. Choose a Reliable Provider

Selecting a trusted provider like rapidefficient ensures your project is handled by experts who understand the demands of precision machining and can adapt to unique project requirements.

3. Utilize Rapid Prototyping

For new designs, consider using rapid prototyping. Precision machining can create functional prototypes that allow for quick testing and refinement before large-scale production.

4. Plan for Regular Quality Checks

Quality checks are essential in high precision machining. Work with a provider that includes thorough inspections in their process to ensure each part meets the required standards.

Conclusion

High precision mechanical machining solutions are vital for industries that prioritize quality and performance. By partnering with an experienced provider like rapidefficient, companies can access reliable, accurate, and efficient machining services tailored to their needs. With their advanced CNC technology, skilled team, and commitment to quality, rapidefficient delivers solutions that enhance product reliability and streamline manufacturing processes.