In the ever-evolving field of precision engineering, 5-axis CNC machining has emerged as a groundbreaking solution for manufacturing complex mechanical components. This technology offers unparalleled accuracy, efficiency, and versatility, enabling businesses to meet stringent requirements across various industries.

What is 5-Axis CNC Machining?

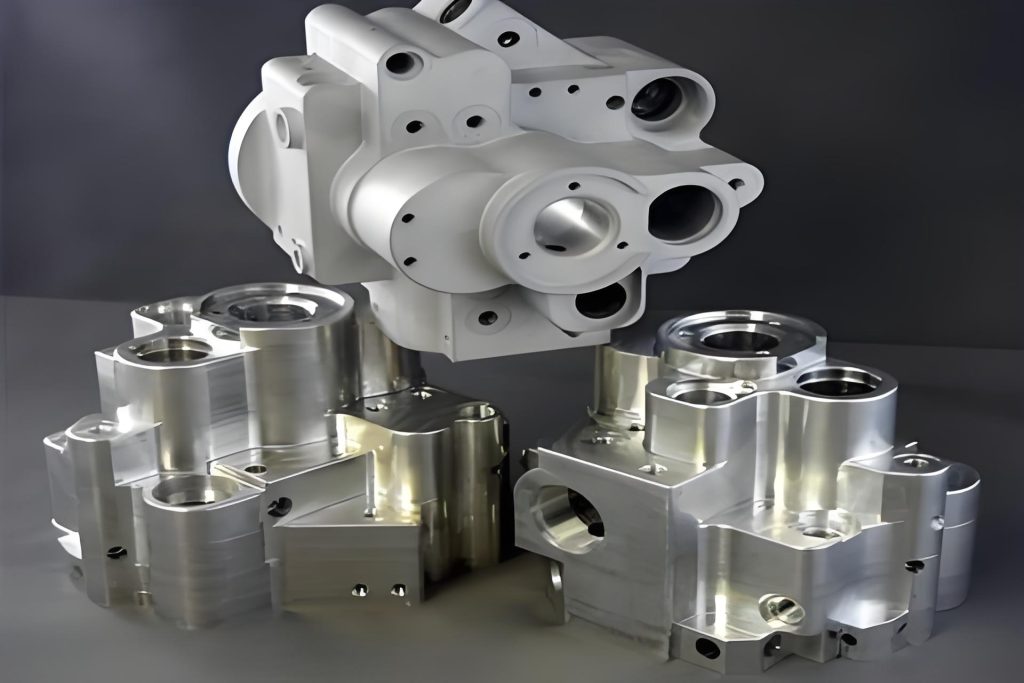

5-axis CNC machining refers to a manufacturing process where the cutting tool can move along five axes simultaneously. Unlike traditional 3-axis machines, which operate along X, Y, and Z planes, 5-axis machines include rotational movements on two additional axes, allowing for intricate geometries and tighter tolerances.

Benefits of 5-Axis CNC Machining

1. Superior Precision and Quality

With enhanced tool access, 5-axis machining minimizes repositioning during operations. This reduces errors and ensures superior surface finishes, making it ideal for complex components in aerospace, automotive, and medical industries.

2. Enhanced Efficiency

By combining multiple machining operations into one setup, 5-axis CNC machines significantly cut production times. Companies like Rapidefficient leverage this capability to deliver faster turnaround times while maintaining cost efficiency.

3. Versatility in Design

The ability to work on complex geometries without additional fixtures or tools empowers manufacturers to create innovative designs, expanding possibilities in product development.

4. Reduced Tool Wear

Thanks to optimal tool orientation, 5-axis machining reduces strain on tools, leading to longer lifespans and consistent performance.

Applications of 5-Axis CNC Machining

This advanced technology is revolutionizing multiple industries:

- Aerospace: Production of turbine blades, engine components, and structural parts with intricate designs.

- Automotive: Manufacturing lightweight, high-precision parts for modern vehicles.

- Medical: Creation of prosthetics, surgical instruments, and implants requiring extreme accuracy.

- Energy: Fabrication of parts for wind turbines and oil exploration equipment.

Why Choose Rapidefficient for 5-Axis CNC Machining?

Rapidefficient stands out in the CNC machining market due to its cutting-edge technology, skilled workforce, and customer-centric approach. Here’s why businesses trust Rapidefficient:

- State-of-the-Art Equipment: Rapidefficient invests in the latest 5-axis CNC machines to ensure precise and consistent results.

- Expertise Across Industries: With years of experience, they understand the unique challenges of various sectors, providing tailored solutions.

- Fast Turnaround Times: Leveraging advanced automation, they deliver projects quickly without compromising quality.

- Competitive Pricing: Their efficient processes reduce costs, making high-quality machining accessible.

- Commitment to Sustainability: By optimizing material usage and energy efficiency, Rapidefficient supports eco-friendly manufacturing.

How to Maximize Results with 5-Axis CNC Machining

- Collaborate Early in Design Stages: Engaging experts like Rapidefficient during the design phase helps optimize parts for manufacturability.

- Leverage Simulation Tools: Advanced software ensures error-free machining and accurate cost estimation.

- Focus on Material Selection: Choosing the right materials improves performance and longevity of components.

Conclusion

5-axis CNC machining is a game-changer for industries demanding precision, speed, and innovation. By partnering with Rapidefficient, businesses gain access to top-tier machining services that drive success. Whether you’re in aerospace, automotive, or medical manufacturing, Rapidefficient offers the expertise and technology to turn your ideas into reality.