Introduction

Overview of CNC Aluminum Machining

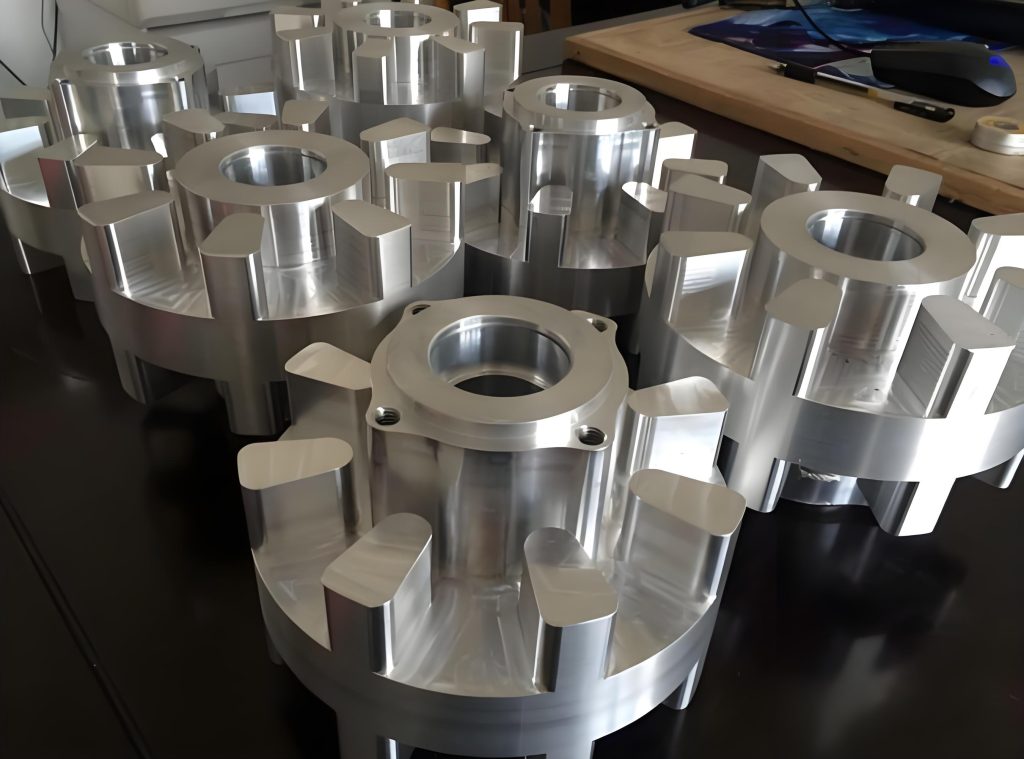

CNC aluminum machining is a highly sophisticated and essential process in various industries. This technology involves the use of computer-controlled machinery to create precise and complex aluminum parts. The importance of CNC aluminum machining cannot be overstated. It offers several significant advantages that contribute to its widespread use.

The importance of precision in CNC aluminum machining is of paramount importance. In industries such as aerospace, automotive, and electronics, tight tolerances are crucial for ensuring the proper functioning and safety of components. CNC machines are capable of achieving extremely high levels of accuracy, ensuring that each part meets the required specifications.

Another aspect of importance is the efficiency of the process. CNC aluminum machining can produce a large number of parts in a relatively short period of time. This is particularly beneficial for industries with high production demands. The automated nature of CNC machines reduces the need for manual labor, minimizing errors and increasing productivity.

The versatility of CNC aluminum machining is also a key factor. It can be used to create a wide variety of shapes and sizes of parts, from simple geometries to complex three-dimensional structures. This allows manufacturers to meet the diverse needs of different industries and applications.

In addition to precision, efficiency, and versatility, CNC aluminum machining also offers cost-effectiveness in the long run. Although the initial investment in CNC machines may be significant, the ability to produce high-quality parts with minimal waste and reduced labor costs can lead to significant savings over time.

Overall, CNC aluminum machining is a crucial technology that plays a vital role in many industries. Its ability to produce precise, efficient, and versatile aluminum parts makes it an indispensable tool for manufacturers seeking to meet the demanding requirements of today’s market.

Importance of CNC Aluminum Machining

Aluminum is widely favored in many applications due to its lightweight nature, excellent thermal conductivity, and corrosion resistance. CNC machining of aluminum holds significant importance as it enables the production of parts that precisely meet the specific requirements of diverse industries such as aerospace, automotive, medical, and electronics.

The importance of this machining process lies in several aspects. Firstly, in industries like aerospace and automotive, where safety and performance are of utmost concern, the precision offered by CNC aluminum machining is crucial. Tight tolerances are essential for ensuring the proper functioning and safety of components. With CNC machines, extremely high levels of accuracy can be achieved, guaranteeing that each part conforms to the required specifications.

Secondly, efficiency is a key factor. CNC aluminum machining can produce a large number of parts in a relatively short period. This is particularly beneficial for industries with high production demands. The automated nature of CNC machines reduces the need for manual labor, minimizing errors and significantly increasing productivity.

Moreover, the versatility of CNC aluminum machining cannot be overlooked. It can create a wide variety of shapes and sizes of parts, ranging from simple geometries to complex three-dimensional structures. This allows manufacturers to meet the diverse needs of different industries and applications.

In addition to precision, efficiency, and versatility, CNC aluminum machining also proves to be cost-effective in the long run. Although the initial investment in CNC machines may be substantial, the ability to produce high-quality parts with minimal waste and reduced labor costs leads to significant savings over time.

In conclusion, CNC aluminum machining is of paramount importance. It plays a vital role in various industries by providing precise, efficient, and versatile aluminum parts. This technology is an indispensable tool for manufacturers striving to meet the demanding requirements of today’s competitive market.

1、Computer Numerical Control (CNC) Technology

Computer technology plays a crucial role in controlling machinery tools in CNC aluminum machining. It enables the achievement of high precision and accuracy, which are essential in various industries.

In the field of machining, computer numerical control technology acts as the backbone. It takes charge of precisely directing the movement and operations of the machinery tools. This is achieved through a series of complex algorithms and programming codes that ensure every action of the machine is accurate and consistent.

The precision offered by computer technology is vital in industries such as aerospace, automotive, and electronics. In these sectors, tight tolerances are non-negotiable for ensuring the proper functioning and safety of components. CNC machines, under the control of computer technology, can achieve extremely high levels of accuracy. For instance, they can ensure that each part conforms precisely to the required specifications, down to the minutest detail.

Efficiency is another significant aspect where computer technology shines. CNC aluminum machining can produce a large number of parts in a relatively short period. This is made possible by the automated nature of CNC machines, which is governed by computer programs. The reduction in the need for manual labor not only minimizes errors but also significantly increases productivity.

Moreover, the versatility of CNC aluminum machining is largely attributed to computer technology. It can create a wide variety of shapes and sizes of parts, ranging from simple geometries to complex three-dimensional structures. This is because computer programs can be customized and adjusted to meet the diverse needs of different industries and applications.

In conclusion, computer technology is the driving force behind CNC aluminum machining. It enables high precision, efficiency, and versatility, making it an indispensable tool in modern manufacturing.

2、Steps in CNC Aluminum Machining

The process of CNC aluminum machining consists of several distinct stages, each playing a crucial role in ensuring the production of high-quality aluminum parts.

2.1. Design and Programming

The first step in CNC aluminum machining is design and programming. This stage involves creating a detailed digital model of the desired part using computer-aided design (CAD) software. Designers use this software to specify the exact dimensions, shapes, and features of the part. Once the design is complete, it is converted into a machine-readable format using computer-aided manufacturing (CAM) software.

The CAM software generates a set of instructions, known as a toolpath, that tells the CNC machine how to move and cut the aluminum material to create the part. These toolpaths take into account factors such as the type of cutting tool to be used, the feed rate (the speed at which the tool moves through the material), and the spindle speed (the speed at which the cutting tool rotates).

2.2. Machining Operations

After the design and programming stage is complete, the actual machining operations can begin. The CNC machine follows the toolpath generated in the previous stage to cut and shape the aluminum material.

There are several types of machining operations that can be performed, including milling, turning, drilling, and grinding. Milling involves removing material from the workpiece using a rotating cutting tool. Turning is used to create cylindrical shapes by rotating the workpiece while a cutting tool is applied. Drilling is used to create holes in the workpiece, and grinding is used to smooth and refine the surface of the part.

During the machining operations, the CNC machine is controlled by a computer program that ensures precise and accurate movements. The machine can perform complex operations with high repeatability, allowing for the production of large quantities of identical parts.

2.3. Inspection and Quality Control

Once the machining operations are complete, the final stage is inspection and quality control. This stage is crucial to ensure that the finished parts meet the required specifications and quality standards.

Inspection can be performed using a variety of methods, including visual inspection, dimensional measurement, and surface finish analysis. Visual inspection involves looking for any visible defects or imperfections in the part, such as cracks, chips, or burrs. Dimensional measurement is used to ensure that the part’s dimensions are within the required tolerances. Surface finish analysis is used to measure the smoothness and texture of the part’s surface.

If any defects or deviations from the specifications are found during inspection, the part may need to be reworked or scrapped. Reworking may involve additional machining operations to correct the defect, while scrapping means that the part is unusable and must be discarded.

In conclusion, the steps involved in CNC aluminum machining are complex and require a high degree of precision and accuracy. From design and programming to machining operations and inspection, each stage plays a crucial role in ensuring the production of high-quality aluminum parts. By following these steps and implementing strict quality control measures, manufacturers can produce parts that meet the demanding requirements of various industries.

Spindle speed, feed rate, and depth of cut are crucial machining parameters that significantly influence the quality of the final product in CNC aluminum machining.

Spindle speed plays a vital role. A proper spindle speed ensures efficient cutting and smooth surface finish. If the spindle speed is too low, it can lead to poor surface quality and increased tool wear. On the other hand, if the speed is too high, it may cause excessive heat generation, which can damage the tool and the workpiece. In industries such as aerospace and electronics, where high precision is required, the selection of the right spindle speed is essential. For example, in the production of aluminum parts for aircraft components, a specific spindle speed is determined based on the material properties and the required tolerances.

Feed rate also has a significant impact on the machining process. The feed rate determines how quickly the cutting tool moves through the material. A too slow feed rate can result in low productivity and increased machining time. Conversely, a too fast feed rate can cause tool breakage and poor surface finish. In CNC aluminum machining, the feed rate is carefully adjusted according to the material hardness, tool type, and cutting depth. For instance, when machining soft aluminum alloys, a higher feed rate can be used compared to harder alloys.

Depth of cut is another important parameter. It refers to the amount of material removed in a single pass. A deep depth of cut can increase productivity but may also lead to excessive tool wear and poor surface quality. On the other hand, a shallow depth of cut may result in longer machining time and lower productivity. In CNC aluminum machining, the depth of cut is selected based on the machine’s power, tool strength, and material properties. For example, when machining thin-walled aluminum parts, a shallow depth of cut is preferred to avoid deformation.

In conclusion, spindle speed, feed rate, and depth of cut are essential machining parameters that must be carefully considered and optimized to achieve high-quality products in CNC aluminum machining. By understanding the relationship between these parameters and the material properties, manufacturers can improve productivity, reduce tool wear, and ensure the quality of the final product. If you are looking for a reliable CNC aluminum machining service provider, consider rapidefficient. With their advanced technology and experienced team, rapidefficient can meet your specific machining needs and deliver high-quality products on time.

Highlight the ability of CNC machining to achieve micron-level precision, making it ideal for applications that require strict tolerances.

CNC aluminum machining is renowned for its high precision, capable of achieving micron-level accuracy. This remarkable precision is crucial in various industries where even the slightest deviation can have significant consequences. In sectors such as aerospace, where safety and performance are of utmost importance, the tight tolerances offered by CNC machining are essential. Components for aircraft must meet extremely strict specifications to ensure the integrity and reliability of the aircraft. Similarly, in the medical field, precision is vital for the production of surgical instruments and implants. The ability of CNC machining to achieve such high levels of accuracy is a result of advanced technology and precise control systems.

The computer-controlled nature of CNC machines allows for consistent and repeatable results. Each operation is executed with exacting precision, ensuring that every part produced meets the required specifications. This consistency is essential for mass production, where thousands of identical parts need to be manufactured with minimal variation. In contrast to traditional machining methods, which may be subject to human error and variation, CNC machining offers a level of precision that is unrivaled.

Moreover, the precision of CNC machining is not limited to simple geometries. It can handle complex three-dimensional shapes with ease, making it suitable for a wide range of applications. Whether it’s the intricate design of a medical device or the complex components of an aerospace engine, CNC machining can deliver the required precision.

In conclusion, the high precision of CNC aluminum machining is a significant advantage that makes it an ideal choice for applications that demand strict tolerances. Its ability to achieve micron-level accuracy, combined with consistency and the capacity to handle complex shapes, sets it apart from other machining methods. If you are looking for a reliable CNC aluminum machining service provider, consider rapidefficient. With their advanced technology and experienced team, rapidefficient can meet your specific machining needs and deliver high-quality products on time.

3、Consistency

In CNC aluminum machining services, consistency is of utmost importance. It emphasizes the ability to produce identical parts, a crucial aspect for mass production.

CNC machining is renowned for its remarkable consistency. The computer-controlled nature of the process ensures that each operation is executed with exact precision, resulting in parts that are virtually identical in dimensions and shape. This level of consistency is essential in industries where large quantities of parts are required, such as the automotive and electronics sectors.

For example, in the automotive industry, components need to fit precisely to ensure the smooth functioning and safety of the vehicle. CNC aluminum machining guarantees that each part meets the strict tolerances required, minimizing the risk of assembly issues and enhancing the overall quality of the product.

The consistency achieved through CNC machining also extends to complex three-dimensional structures. Whether it’s a detailed aerospace component or a sophisticated medical device part, CNC technology can reproduce intricate designs with remarkable accuracy and repeatability.

Moreover, the use of advanced software and programming in CNC machining allows for easy adjustments and modifications to meet specific design requirements. This flexibility does not compromise the consistency of the production process. Manufacturers can quickly adapt to changes in design specifications while still maintaining the high level of uniformity in the manufactured parts.

In conclusion, the consistency offered by CNC aluminum machining is a significant advantage that makes it an ideal choice for industries that demand large quantities of identical, high-quality parts. rapidefficient is a leading provider of CNC aluminum machining services, known for its commitment to precision, consistency, and quality. With their advanced technology and experienced team, rapidefficient can meet your specific machining needs and ensure consistent production of top-notch aluminum parts.

Automation in CNC aluminum machining significantly reduces human error and increases production efficiency.

The computer-controlled nature of CNC machines enables automation, which plays a crucial role in ensuring precision and consistency. With automation, the risk of human error is minimized as the machines follow pre-programmed instructions with exacting precision. This is especially important in industries where even the slightest deviation can have significant consequences, such as aerospace and medical equipment manufacturing.

For example, in the production of complex aluminum parts for aircraft engines, automation ensures that each part is manufactured to extremely tight tolerances. Human operators may be prone to errors due to fatigue, distractions, or variations in skill levels. However, with automated CNC machines, the process is consistent and reliable, reducing the likelihood of defects and ensuring the safety and performance of the final product.

In addition to reducing errors, automation also increases production efficiency. CNC machines can operate continuously without the need for breaks, significantly increasing the number of parts that can be produced in a given time. This is particularly beneficial for industries with high production demands, such as the automotive industry.

Automation also allows for faster setup times and changes in production. With advanced software and programming, adjustments can be made quickly and easily, enabling manufacturers to respond to changing market demands and customer requirements.

Moreover, the use of automation in CNC aluminum machining can lead to cost savings in the long run. By reducing human error and increasing productivity, manufacturers can produce high-quality parts with less waste and lower labor costs.

In conclusion, automation in CNC aluminum machining is a key factor in reducing human error and increasing production efficiency. It enables manufacturers to produce precise and consistent aluminum parts, meeting the demanding requirements of various industries. If you are looking for a reliable CNC aluminum machining service provider, consider rapidefficient. With their advanced automation technology and experienced team, rapidefficient can meet your specific machining needs and deliver high-quality products on time.

4、Flexibility

CNC aluminum machining services offer remarkable flexibility through simple programming changes. This ability to adapt to different designs is a crucial advantage in today’s dynamic manufacturing environment.

The computer-controlled nature of CNC machines allows for easy adjustments to the machining process. By making changes to the programming, manufacturers can quickly switch between different product designs without the need for extensive retooling. This flexibility is especially beneficial for businesses that need to respond quickly to changing market demands or produce small batches of diverse products.

For example, in the electronics industry, product designs can change rapidly. CNC aluminum machining enables manufacturers to quickly adapt to these changes by simply modifying the programming. This allows them to produce the latest components with minimal downtime and cost.

Moreover, the flexibility of CNC machining extends to complex three-dimensional designs. Whether it’s a unique shape for a medical device or a custom part for an aerospace application, CNC technology can handle it with ease. The advanced software and programming capabilities of CNC machines allow for precise control over every aspect of the machining process, ensuring that even the most intricate designs can be accurately reproduced.

In conclusion, the flexibility offered by CNC aluminum machining services is a significant asset for manufacturers. It enables them to adapt quickly to changing design requirements, produce diverse products efficiently, and stay competitive in today’s fast-paced market. If you are looking for a CNC aluminum machining service provider that offers exceptional flexibility, consider rapidefficient. With their advanced technology and experienced team, rapidefficient can meet your specific design needs and deliver high-quality products on time.

5、Safety

Automated operations in CNC aluminum machining significantly reduce the risk of accidents. The computer-controlled nature of CNC machines ensures precise and consistent movements, minimizing the potential for human error that can lead to accidents. In traditional machining processes, human operators are often exposed to various risks such as being caught in moving parts or dealing with sharp tools. However, with automated CNC machining, the majority of operations are carried out by machines following pre-programmed instructions.

For example, in the aerospace industry where safety is of utmost importance, the use of automated CNC aluminum machining reduces the risk of accidents during the production of critical components. The machines can operate continuously without fatigue or distraction, ensuring a higher level of safety compared to manual operations.

Moreover, automated CNC machining also reduces the need for workers to be in close proximity to dangerous machinery. This not only lowers the risk of physical injuries but also improves overall workplace safety.

In conclusion, the automated operations in CNC aluminum machining play a crucial role in reducing the risk of accidents. This makes it a safer option for manufacturers, especially in industries where safety is a top priority. If you are looking for a reliable CNC aluminum machining service provider that prioritizes safety, consider rapidefficient. With their advanced automation technology and strict safety measures, rapidefficient can ensure a safe and efficient machining process.

5.1 Factors to Consider

When it comes to material selection for aluminum parts, several factors need to be considered. Thermal conductivity, strength, and corrosion resistance are crucial aspects that play a significant role in choosing the right aluminum material.

Thermal Conductivity: Thermal conductivity is an important property of aluminum materials. It refers to the ability of a material to conduct heat. In applications where heat dissipation is essential, such as in electronics and some industrial processes, a high thermal conductivity is desirable. Aluminum alloys with good thermal conductivity can efficiently transfer heat away from sensitive components, preventing overheating and ensuring the proper functioning of the system. For example, in the production of computer components, aluminum parts with high thermal conductivity are often used to dissipate the heat generated by the processors and other electronic devices.

Strength: The strength of aluminum materials is another crucial factor. Different applications require different levels of strength. In industries such as aerospace and automotive, where safety and performance are of utmost importance, materials with high strength are essential. Aluminum alloys can be designed to have varying levels of strength by adjusting the composition and processing methods. For instance, some aluminum alloys are strengthened through heat treatment or the addition of alloying elements such as copper, magnesium, and zinc. These alloys can offer excellent strength-to-weight ratios, making them ideal for applications where weight reduction is a priority.

Corrosion Resistance: Corrosion resistance is also a significant consideration when selecting aluminum materials. Aluminum has a natural oxide layer that provides some degree of corrosion protection. However, in certain environments, such as those with high humidity or exposure to corrosive chemicals, additional corrosion resistance may be required. Aluminum alloys can be formulated to enhance their corrosion resistance by adding elements such as chromium, nickel, or titanium. These alloys can withstand harsh environments and maintain their integrity over long periods of time. For example, in marine applications, aluminum parts with high corrosion resistance are essential to prevent degradation due to saltwater exposure.

In conclusion, when choosing aluminum materials for parts, it is essential to consider factors such as thermal conductivity, strength, and corrosion resistance. By carefully evaluating these factors and selecting the right aluminum alloy, manufacturers can ensure the production of high-quality parts that meet the specific requirements of their applications. If you are looking for a reliable CNC aluminum machining service provider that can help you select the right materials for your projects, consider rapidefficient. With their expertise in material selection and advanced machining capabilities, rapidefficient can deliver high-quality aluminum parts that meet your exact specifications.

5.2 Popular Aluminum Alloys for CNC Machining

Aluminum alloys are widely used in CNC machining due to their unique characteristics. Some of the commonly used aluminum alloys in CNC machining include 6061 and 7075 alloys.

6061 aluminum alloy is known for its excellent combination of strength, corrosion resistance, and weldability. It has good thermal conductivity and can be easily machined into various shapes. In applications such as automotive parts and structural components, 6061 alloy is a popular choice. For example, in the production of motorcycle frames, 6061 alloy offers the required strength and durability while keeping the weight relatively low.

7075 aluminum alloy, on the other hand, is renowned for its high strength and hardness. It is often used in aerospace and military applications where lightweight and high-performance materials are essential. The alloy has a relatively low thermal conductivity compared to 6061 but offers superior strength-to-weight ratio. For instance, in the manufacturing of aircraft parts, 7075 alloy can withstand the extreme stresses and loads encountered during flight.

Another commonly used alloy is 5052 aluminum alloy. This alloy has good formability, corrosion resistance, and moderate strength. It is often used in applications such as enclosures, brackets, and panels. The alloy’s good formability allows for complex shapes to be easily created through CNC machining.

In conclusion, different aluminum alloys offer specific characteristics that make them suitable for various applications in CNC machining. Manufacturers need to carefully consider the requirements of their projects and select the appropriate alloy to ensure high-quality and reliable parts. If you are looking for a reliable CNC aluminum machining service provider that can work with different alloys, consider rapidefficient. With their expertise and advanced technology, rapidefficient can handle a wide range of aluminum alloys and deliver high-quality products on time.

6、Preparing the CNC Machine for Aluminum Machining

6.1 Machine Setup

Preparing a CNC machine for aluminum machining is a crucial step to ensure high-quality and efficient production. The process involves several important aspects, including tool selection and calibration.

Tool Selection

Selecting the right cutting tools is essential for successful aluminum machining. Different tools are designed for specific machining operations and aluminum alloys. For example, end mills with specific geometries and coatings are suitable for milling aluminum, while drills are used for creating holes. The choice of tool depends on factors such as the part’s geometry, the required surface finish, and the machining parameters.

In industries like aerospace and electronics, where precision is critical, high-quality cutting tools are essential. These tools are often made of materials that can withstand the high speeds and forces involved in CNC machining. They also have features such as sharp cutting edges and excellent wear resistance to ensure accurate and efficient cutting.

Calibration

Calibration is a critical process that ensures the accuracy and precision of the CNC machine. It involves adjusting and verifying the machine’s settings to ensure that it operates within the required tolerances.

The calibration process typically includes checking and adjusting the machine’s axes, spindle speed, feed rate, and tool offsets. This is done using specialized calibration tools and software. For example, a laser interferometer can be used to measure the accuracy of the machine’s axes, while a tool setter can be used to accurately set the tool lengths.

Calibration is an ongoing process and should be performed regularly to ensure the continued accuracy and performance of the CNC machine. This is especially important for aluminum machining, where tight tolerances are often required.

In conclusion, setting up a CNC machine for aluminum machining involves careful tool selection and calibration. By taking these steps, manufacturers can ensure high-quality and efficient production of aluminum parts. rapidefficient is a leading provider of CNC aluminum machining services, with expertise in tool selection and calibration. They can help you set up your CNC machine for optimal performance and deliver high-quality aluminum parts on time.

6.2 Coolant Use

Coolant plays a crucial role in the CNC aluminum machining process. It has a significant impact on tool life and surface finish.

In the machining process, coolant helps to dissipate heat generated during cutting. This is essential as excessive heat can lead to tool wear and damage, reducing the lifespan of the cutting tools. By effectively cooling the cutting zone, coolant helps to maintain the integrity of the tools, allowing them to perform at optimal levels for a longer period.

Moreover, coolant also has a positive effect on surface finish. It helps to flush away chips and debris, preventing them from interfering with the cutting process and resulting in a smoother surface finish. A good surface finish is important in many applications, as it not only enhances the aesthetic appeal of the part but also improves its functionality. For example, in the aerospace industry, smooth surface finishes are crucial for reducing drag and improving aerodynamic performance.

In conclusion, coolant is an essential component of the CNC aluminum machining process. Its role in cooling the cutting zone and improving surface finish makes it indispensable for achieving high-quality results and prolonging tool life. rapidefficient, as a leading CNC aluminum machining service provider, understands the importance of coolant and uses it effectively to ensure the best possible results for their clients.

7、Fine-Tuning Machining Parameters

Adjusting machining parameters is crucial for optimizing precision and surface quality in CNC aluminum machining. Spindle speed, feed rate, and depth of cut are three key parameters that significantly influence the final product.

Spindle speed plays a vital role. A proper spindle speed ensures efficient cutting and a smooth surface finish. For instance, in industries like aerospace and electronics where high precision is required, the selection of the right spindle speed is essential. If the spindle speed is too low, it can lead to poor surface quality and increased tool wear. Conversely, if it is too high, it may cause excessive heat generation, which can damage the tool and the workpiece.

Feed rate also has a significant impact on the machining process. It determines how quickly the cutting tool moves through the material. A too slow feed rate can result in low productivity and increased machining time. On the other hand, a too fast feed rate can cause tool breakage and poor surface finish. The feed rate is carefully adjusted according to factors such as material hardness, tool type, and cutting depth. For example, when machining soft aluminum alloys, a higher feed rate can be used compared to harder alloys.

Depth of cut is another important parameter. It refers to the amount of material removed in a single pass. A deep depth of cut can increase productivity but may also lead to excessive tool wear and poor surface quality. Conversely, a shallow depth of cut may result in longer machining time and lower productivity. The depth of cut is selected based on the machine’s power, tool strength, and material properties. For instance, when machining thin-walled aluminum parts, a shallow depth of cut is preferred to avoid deformation.

By carefully considering and optimizing these machining parameters, manufacturers can improve productivity, reduce tool wear, and ensure the quality of the final product. If you are looking for a reliable CNC aluminum machining service provider, consider rapidefficient. With their advanced technology and experienced team, rapidefficient can meet your specific machining needs and deliver high-quality products on time.

8、Tool Maintenance

Keeping the cutting tools sharp and in good condition is of utmost importance in CNC aluminum machining services. Sharp tools ensure efficient cutting and a smooth surface finish on the aluminum parts.

A dull cutting tool can lead to several issues. Firstly, it can result in poor surface quality, with visible marks and roughness on the workpiece. This not only affects the aesthetic appeal of the part but also can impact its functionality in applications where a smooth surface is crucial. For example, in the aerospace industry, even a minor imperfection on a part’s surface can affect aerodynamic performance.

Secondly, a dull tool can cause increased tool wear. As the tool struggles to cut through the aluminum material, it experiences higher levels of friction and stress, leading to faster degradation. This not only requires more frequent tool changes, which can disrupt the production process and increase costs, but also can affect the dimensional accuracy of the parts being machined.

In addition, a dull tool can generate excessive heat during cutting. This heat can damage the tool itself and the workpiece, potentially leading to warping or other forms of deformation. In industries such as electronics, where tight tolerances are essential, any deviation from the required dimensions can render the part unusable.

To maintain the cutting tools in good condition, regular inspection and maintenance are essential. This includes checking for signs of wear such as chipped edges or reduced sharpness. When necessary, tools should be sharpened or replaced to ensure optimal performance.

Moreover, proper storage and handling of tools can also contribute to their longevity. Keeping tools clean and dry, and protecting them from damage during storage and transportation, can help maintain their sharpness and integrity.

In conclusion, maintaining sharp and well-conditioned cutting tools is crucial for ensuring high-quality and efficient CNC aluminum machining. By paying attention to tool maintenance, manufacturers can improve productivity, reduce costs, and deliver parts that meet the demanding requirements of various industries. If you are looking for a reliable CNC aluminum machining service provider that emphasizes tool maintenance, consider rapidefficient. With their commitment to quality and attention to detail, rapidefficient can ensure that your machining projects are completed with the highest level of precision and efficiency.

9、Inspection and Quality Control

9.1 Methods for Quality Assurance

Inspection techniques play a crucial role in ensuring the quality of CNC machined aluminum parts. In the realm of CNC aluminum machining services, quality assurance is of paramount importance. Various methods are employed to achieve high-quality results.

One of the key inspection methods is dimensional measurement. This involves using precision measuring tools to ensure that the dimensions of the machined parts are within the required tolerances. For example, calipers and micrometers can be used to measure the length, width, and height of the parts. By comparing the measured dimensions with the design specifications, any deviations can be identified and corrected.

Visual inspection is another important technique. This involves examining the parts visually for any visible defects such as cracks, chips, or burrs. Trained inspectors look for these defects and determine if the part is acceptable or needs to be reworked or scrapped. In industries such as aerospace and electronics, where even the slightest defect can have serious consequences, visual inspection is carried out meticulously.

Surface finish analysis is also an essential part of quality assurance. The smoothness and texture of the part’s surface are measured to ensure that it meets the required standards. This is particularly important in applications where the surface finish can affect the functionality or aesthetic appeal of the part. For example, in the automotive industry, a smooth surface finish is desired for parts that are visible to the consumer.

In addition to these methods, advanced inspection technologies such as coordinate measuring machines (CMMs) are also used. CMMs can measure the dimensions and geometry of the parts with extremely high accuracy. They can detect even the smallest deviations from the design specifications and provide detailed reports on the quality of the parts.

Quality inspection in CNC aluminum machining is not only about detecting defects but also about ensuring consistency. As mentioned earlier, consistency is crucial in mass production. Inspection techniques help to ensure that each part produced is identical to the others in terms of dimensions, shape, and quality. This is achieved by regularly checking and calibrating the CNC machines and using standardized inspection procedures.

Moreover, quality assurance also involves documentation and record-keeping. All inspection results are documented, including the dimensions measured, any defects found, and the actions taken to correct them. This documentation is essential for traceability and quality control purposes. It allows manufacturers to identify trends and patterns in the production process and take corrective actions if necessary.

In conclusion, inspection techniques are essential for ensuring the quality of CNC machined aluminum parts. By using a combination of dimensional measurement, visual inspection, surface finish analysis, and advanced inspection technologies, manufacturers can ensure that their products meet the highest quality standards. rapidefficient, as a leading CNC aluminum machining service provider, employs these inspection techniques to deliver high-quality products to its customers. With their commitment to quality and attention to detail, rapidefficient is a reliable choice for all your CNC aluminum machining needs.

Early detection of defects in CNC aluminum machining is crucial as it can save significant time and resources. In the CNC aluminum machining process, defects can occur at various stages, from design and programming to machining operations and final inspection. Detecting these defects early on allows for timely corrective actions, minimizing the need for rework or scrapping of parts.

For example, if a defect is identified during the design and programming stage, adjustments can be made easily without incurring significant costs or delays. Similarly, detecting defects during machining operations can prevent further damage to the workpiece and tools, reducing the overall production time and resource consumption.

Moreover, early defect detection helps in maintaining the quality standards of the final product. In industries such as aerospace and automotive, where precision and safety are of utmost importance, even a minor defect can have serious consequences. By detecting and addressing defects early, manufacturers can ensure that the parts meet the required specifications and perform reliably.

In conclusion, early detection of defects in CNC aluminum machining is essential for saving time and resources while maintaining high-quality standards. This not only benefits the manufacturers but also ensures the safety and performance of the end products. rapidefficient, as a leading CNC aluminum machining service provider, emphasizes early defect detection to deliver high-quality products on time and within budget.

9.2 Surface Finishing Options

In the field of CNC aluminum machining, different surface finishing options are available to enhance the appearance and functionality of aluminum parts. Two popular finishing processes are anodizing and powder coating.

Anodizing

Anodizing is a surface treatment process that increases the thickness of the natural oxide layer on the surface of aluminum. This process not only provides a decorative finish but also offers several benefits. Anodized aluminum has excellent corrosion resistance, making it suitable for applications in harsh environments. It also has a hard and durable surface that resists scratches and abrasion. Additionally, anodizing allows for a wide range of colors to be achieved, giving designers more options for creating aesthetically pleasing parts.

For example, in the electronics industry, anodized aluminum enclosures are commonly used to protect sensitive components. The anodized finish provides a sleek and professional look while also offering protection against moisture and dust.

Powder Coating

Powder coating is another popular surface finishing option for aluminum parts. This process involves applying a dry powder electrostatically to the surface of the part and then curing it in an oven. Powder coating provides a smooth and uniform finish that is highly resistant to chipping, fading, and corrosion. It also offers excellent color retention and can be applied in a wide variety of colors and finishes.

In applications such as automotive and architectural components, powder coating is often used to give aluminum parts a durable and attractive finish. The powder coating process can be customized to meet specific requirements, such as high-temperature resistance or chemical resistance.

In conclusion, anodizing and powder coating are two effective surface finishing options for CNC aluminum parts. Each process has its own unique advantages and can be chosen based on the specific needs of the application. Whether it’s for corrosion resistance, aesthetics, or durability, these finishing processes can enhance the quality and performance of aluminum parts. If you are looking for a reliable CNC aluminum machining service provider that offers surface finishing options, consider rapidefficient. With their expertise in anodizing and powder coating, rapidefficient can help you achieve the perfect finish for your aluminum parts.

9.3 Assembly Considerations

In assembling CNC machined aluminum parts, there are several challenges and best practices to consider.

Challenges

One of the main challenges is ensuring proper alignment and fit of the parts. Due to the high precision of CNC machining, even small deviations in dimensions can lead to difficulties in assembly. For example, if a hole is machined slightly off-center or a part is not within the required tolerances, it can cause problems when trying to assemble multiple components.

Another challenge is dealing with the potential for damage during assembly. Aluminum parts can be easily scratched or dented, especially if they are handled roughly. This can affect the appearance and functionality of the final product. In addition, some assembly methods may require the use of tools or fixtures that can also cause damage if not used properly.

Best Practices

To overcome these challenges, several best practices can be followed. First, careful inspection of the parts before assembly is essential. This includes checking dimensions, surface finish, and any potential defects. Using precision measuring tools such as calipers and micrometers can help ensure that the parts meet the required specifications.

Proper handling and storage of the parts is also crucial. Aluminum parts should be stored in a clean, dry environment to prevent corrosion and damage. During assembly, they should be handled with care to avoid scratches and dents. Using soft gloves or padded tools can help minimize the risk of damage.

Another best practice is to use appropriate assembly methods and tools. For example, when fastening parts together, using the correct size and type of screws or bolts can ensure a secure fit without causing damage. In some cases, specialized fixtures or jigs may be needed to hold the parts in place during assembly.

In conclusion, assembling CNC machined aluminum parts requires careful attention to detail and the implementation of best practices to ensure a successful outcome. By addressing the challenges and following these guidelines, manufacturers can produce high-quality products that meet the demanding requirements of various industries. rapidefficient, as a leading CNC aluminum machining service provider, has the expertise and experience to handle the assembly process effectively and ensure the quality of the final product.

10、Case Studies

10.1 Success Stories in Various Industries

In various industries, CNC aluminum machining has delivered remarkable success stories. Let’s take a look at some real-life examples in aerospace, automotive, medical, and other sectors.

Aerospace Industry

In the aerospace sector, precision is of utmost importance. Components for aircraft must meet extremely strict specifications to ensure the integrity and reliability of the aircraft. CNC aluminum machining plays a crucial role in producing parts such as engine components, structural elements, and control surfaces. For example, rapidefficient has been involved in the production of aluminum parts for a leading aerospace company. Through advanced CNC technology, they were able to achieve micron-level precision, ensuring that each part conformed precisely to the required specifications. The high strength and lightweight nature of aluminum, combined with the precision of CNC machining, made these parts ideal for aerospace applications.

Automotive Industry

The automotive industry also benefits greatly from CNC aluminum machining. Components such as engine blocks, transmission cases, and suspension parts can be made with high precision and efficiency. For instance, a major automotive manufacturer turned to rapidefficient for the production of aluminum parts for their high-performance sports cars. The use of CNC machining allowed for consistent production of identical parts, ensuring a smooth assembly process and optimal performance. The corrosion resistance and durability of aluminum, along with the flexibility and speed of CNC machining, made it an ideal choice for the automotive industry.

Medical Industry

In the medical field, precision and sterility are crucial. CNC aluminum machining is used to produce surgical instruments, implants, and medical equipment components. For example, rapidefficient has worked with a leading medical device company to produce aluminum parts for a new generation of imaging equipment. The tight tolerances and smooth surface finish achieved through CNC machining were essential for the proper functioning and safety of these medical devices. The biocompatibility of aluminum and the ability to produce complex shapes made it an ideal material for medical applications.

Other Sectors

CNC aluminum machining is also widely used in other sectors such as electronics, telecommunications, and consumer goods. In the electronics industry, aluminum enclosures and heat sinks are produced with high precision to protect sensitive components and dissipate heat. In the telecommunications industry, aluminum parts are used in antennas and communication equipment. And in the consumer goods industry, aluminum is used in products such as laptops, smartphones, and home appliances.

In conclusion, CNC aluminum machining has proven to be a highly successful technology in various industries. Its ability to produce precise, efficient, and versatile aluminum parts makes it an indispensable tool for manufacturers seeking to meet the demanding requirements of today’s market. rapidefficient is a leading provider of CNC aluminum machining services, with a track record of success in multiple industries. Whether it’s aerospace, automotive, medical, or any other sector, rapidefficient can deliver high-quality products on time and within budget.

10.2 Lessons Learned

The case studies presented earlier offer several key takeaways. Firstly, the precision offered by CNC aluminum machining is crucial in industries like aerospace, automotive, and electronics. The ability to achieve micron-level accuracy ensures that components meet strict tolerances, enhancing safety and performance. For example, in aerospace applications, precise CNC machining of aluminum parts is essential for the integrity and reliability of aircraft.

Consistency is another important lesson. CNC machining is renowned for its ability to produce identical parts, which is vital for mass production. This consistency is achieved through the computer-controlled nature of the process, ensuring that each operation is executed with exact precision. In industries such as the automotive sector, where components need to fit precisely for smooth functioning and safety, CNC aluminum machining guarantees the required tolerances.

Automation in CNC aluminum machining significantly reduces human error and increases production efficiency. The computer-controlled machines follow pre-programmed instructions, minimizing the risk of defects caused by human factors. This is particularly beneficial in industries where even the slightest deviation can have serious consequences, such as aerospace and medical equipment manufacturing.

The flexibility offered by CNC aluminum machining services is also a valuable lesson. Through simple programming changes, manufacturers can adapt to different designs quickly, enabling them to respond to changing market demands and produce small batches of diverse products. This flexibility is especially useful in industries like electronics, where product designs change rapidly.

Finally, safety is a crucial aspect. Automated operations in CNC aluminum machining reduce the risk of accidents by ensuring precise and consistent movements, minimizing the potential for human error. In industries where safety is a top priority, such as aerospace, the use of automated CNC machining is essential.

In conclusion, these lessons learned from the case studies highlight the importance of precision, consistency, automation, flexibility, and safety in CNC aluminum machining. By understanding and applying these principles, manufacturers can improve productivity, reduce costs, and deliver high-quality products that meet the demanding requirements of various industries. rapidefficient, as a leading CNC aluminum machining service provider, embodies these qualities and can help you achieve your machining goals.

11、Why Choose Rapidefficient as a CNC Machining Service Provider

11.1 Expertise and Experience

Rapidefficient stands out as a premier CNC machining service provider with years of extensive experience in the field. The company boasts a team of highly skilled professionals who are dedicated to delivering top-notch quality and service.

Rapidefficient’s expertise is evident in every aspect of CNC machining. Their in-depth knowledge of the process enables them to handle complex projects with ease and precision. Whether it’s aerospace components with strict tolerances or intricate medical devices, the team at Rapidefficient has the know-how to meet the diverse needs of different industries.

The company’s years of experience have also allowed them to refine their processes and techniques. They continuously invest in state-of-the-art technology and equipment to stay at the forefront of the industry. This commitment to innovation ensures that Rapidefficient can offer the highest level of precision and efficiency in CNC machining.

Moreover, Rapidefficient’s team is trained to handle a wide range of materials, including various aluminum alloys. They understand the unique properties of each alloy and can select the most appropriate one for a specific project. This expertise in material selection further enhances the quality and performance of the final product.

In conclusion, Rapidefficient’s expertise and experience make it an ideal choice for CNC machining services. Whether it’s a small batch production or a large-scale project, the company can deliver high-quality results on time and within budget.

11.2 State-of-the-Art Equipment

Describe the advanced machinery and technology used by Rapidefficient.

Rapidefficient is renowned for its state-of-the-art equipment, which plays a crucial role in delivering high-quality CNC aluminum machining services. The company’s machinery is equipped with the latest technology to ensure precision, efficiency, and versatility.

One of the key features of Rapidefficient’s equipment is its advanced computer numerical control (CNC) systems. These systems enable precise control over the machining process, allowing for micron-level precision. The CNC technology allows for complex geometries and three-dimensional shapes to be created with ease, meeting the diverse needs of different industries.

The machines at Rapidefficient are also designed for high-speed operation. With advanced spindle speeds and feed rates, they can produce a large number of parts in a relatively short period. This not only increases productivity but also reduces production time and costs.

In addition to speed, the equipment is known for its durability and reliability. Made from high-quality materials, the machines can withstand the rigors of continuous operation without sacrificing precision. This ensures consistent quality and performance over time.

Another aspect of Rapidefficient’s state-of-the-art equipment is its automation capabilities. Automated operations reduce human error and increase production efficiency. The machines can follow pre-programmed instructions with exact precision, ensuring that each part is manufactured to the highest standards.

Moreover, Rapidefficient invests in continuous research and development to stay at the forefront of technology. This allows the company to incorporate the latest advancements into its equipment, providing customers with the best possible machining services.

In conclusion, Rapidefficient’s state-of-the-art equipment is a testament to its commitment to quality and innovation. With advanced CNC systems, high-speed operation, durability, automation, and a focus on research and development, Rapidefficient is able to meet the demanding requirements of various industries and deliver high-quality CNC aluminum machining services.

11.3 Quality Assurance

Highlight the company’s commitment to quality through strict inspection and testing procedures.

Rapidefficient is unwavering in its commitment to quality. This commitment is evident through a series of strict inspection and testing procedures that ensure the highest level of precision and performance in CNC aluminum machining services.

One of the key aspects of quality assurance at Rapidefficient is the use of advanced inspection technologies. Coordinate measuring machines (CMMs), for example, are employed to measure the dimensions and geometry of machined parts with extreme accuracy. These machines can detect even the smallest deviations from the design specifications, providing detailed reports on the quality of the parts.

Visual inspection also plays a crucial role. Trained inspectors meticulously examine each part for visible defects such as cracks, chips, or burrs. In industries like aerospace and electronics, where even the slightest imperfection can have serious consequences, this level of scrutiny is essential.

Surface finish analysis is another important part of the quality assurance process. The smoothness and texture of the part’s surface are measured to ensure it meets the required standards. This is particularly significant in applications where the surface finish can affect functionality or aesthetic appeal.

In addition to these inspection methods, Rapidefficient conducts regular testing of materials and machining processes. This includes testing the strength, corrosion resistance, and thermal conductivity of aluminum alloys to ensure they meet the specific requirements of different applications.

The company’s strict quality control procedures are not only about detecting defects but also ensuring consistency. Through careful calibration of CNC machines and the use of standardized inspection procedures, Rapidefficient guarantees that each part produced is identical to the others in terms of dimensions, shape, and quality.

Documentation and record-keeping are also integral to quality assurance. All inspection results are carefully documented, including the dimensions measured, any defects found, and the actions taken to correct them. This documentation is essential for traceability and quality control purposes, allowing the company to identify trends and patterns in the production process and take corrective actions if necessary.

In conclusion, Rapidefficient’s commitment to quality is demonstrated through its strict inspection and testing procedures. By employing advanced inspection technologies, conducting regular testing, ensuring consistency, and maintaining detailed documentation, Rapidefficient is able to deliver high-quality CNC aluminum machining services that meet the demanding requirements of various industries.

12、Customer Satisfaction

Share testimonials from satisfied customers to demonstrate the company’s reliability and service quality.

Customers around the world have praised Rapidefficient for its outstanding CNC aluminum machining services. One customer from the aerospace industry said, “We needed precision parts for our aircraft components, and Rapidefficient delivered exactly what we were looking for. Their attention to detail and high level of accuracy are truly remarkable.”

In the automotive sector, a major manufacturer commented, “Rapidefficient’s CNC machining services have been a game-changer for us. The consistent quality and timely delivery of aluminum parts have helped us streamline our production process and meet the high demands of our customers.”

The medical field has also benefited from Rapidefficient’s expertise. A leading medical device company stated, “The quality and precision of the aluminum parts produced by Rapidefficient are essential for the safety and effectiveness of our medical devices. We are extremely satisfied with their service.”

These testimonials are just a few examples of the many satisfied customers who have experienced the reliability and service quality of Rapidefficient. Whether it’s aerospace, automotive, medical, or any other industry, Rapidefficient is committed to providing top-notch CNC aluminum machining services that meet the unique needs of each customer.

12.1 Summary of Key Points

CNC aluminum machining offers several key advantages and features. Precision is a standout aspect, capable of achieving micron-level accuracy, which is crucial in industries like aerospace and electronics where even the slightest deviation can have significant consequences. Efficiency is another major benefit, as CNC machines can produce a large number of parts in a relatively short period, reducing the need for manual labor and increasing productivity. The versatility of CNC aluminum machining allows it to create a wide variety of shapes and sizes of parts, from simple geometries to complex three-dimensional structures, meeting the diverse needs of different industries. Additionally, CNC aluminum machining is cost-effective in the long run, despite the initial investment in CNC machines. The ability to produce high-quality parts with minimal waste and reduced labor costs leads to significant savings over time. Automation in CNC aluminum machining further reduces human error and increases production efficiency, while also enhancing safety by minimizing the risk of accidents. The flexibility offered by simple programming changes enables manufacturers to adapt quickly to different designs. Material selection is also important, considering factors such as thermal conductivity, strength, and corrosion resistance. Popular aluminum alloys for CNC machining include 6061 and 7075 alloys. Preparing the CNC machine for aluminum machining involves careful tool selection and calibration, as well as the use of coolant. Fine-tuning machining parameters and maintaining cutting tools are crucial for optimizing precision and surface quality. Inspection and quality control methods ensure the quality of CNC machined aluminum parts, including dimensional measurement, visual inspection, surface finish analysis, and the use of advanced inspection technologies. Surface finishing options like anodizing and powder coating enhance the appearance and functionality of aluminum parts. Assembly considerations include challenges such as ensuring proper alignment and fit of parts and dealing with potential damage, as well as best practices such as careful inspection, proper handling and storage of parts, and using appropriate assembly methods and tools. Case studies in various industries demonstrate the success of CNC aluminum machining, and lessons learned highlight the importance of precision, consistency, automation, flexibility, and safety. Rapidefficient is a reliable CNC machining service provider, with expertise and experience, state-of-the-art equipment, a commitment to quality assurance through strict inspection and testing procedures, and a track record of customer satisfaction.

12.2 Future Outlook

The field of CNC aluminum machining holds great potential for growth and innovation. As technology continues to advance, we can expect to see several developments that will shape the future of this industry.

One area of growth is in the improvement of machining precision. Currently, CNC aluminum machining can achieve micron-level precision, which is crucial for applications in industries such as aerospace and electronics. In the future, we can anticipate even greater levels of accuracy as new technologies and techniques are developed. For example, advancements in computer control systems and cutting tools may enable even tighter tolerances and smoother surface finishes.

Innovation in materials is also likely to drive growth in the field. As the demand for lightweight and high-performance materials continues to increase, researchers are constantly exploring new aluminum alloys and composite materials that offer improved strength, corrosion resistance, and thermal conductivity. These new materials will open up new possibilities for CNC machining, allowing for the production of more complex and specialized parts.

Automation and robotics will play an increasingly important role in the future of CNC aluminum machining. As the cost of automation technology continues to decline, more manufacturers will adopt automated systems to reduce labor costs and increase production efficiency. Robotic arms and automated conveyor systems can work alongside CNC machines to handle material loading and unloading, tool changes, and quality inspection tasks. This will not only improve productivity but also enhance workplace safety by reducing the risk of human error and accidents.

The integration of artificial intelligence and machine learning is another area of potential innovation. These technologies can be used to optimize machining parameters, predict tool wear, and detect defects in real-time. By analyzing large amounts of data from previous machining operations, AI systems can learn to make more informed decisions and improve the overall quality and efficiency of the machining process.

In addition to these technological advancements, there is also potential for growth in the application of CNC aluminum machining in new industries. For example, as the renewable energy sector continues to expand, there will be a growing demand for precision aluminum parts for wind turbines, solar panels, and energy storage systems. Similarly, the growing popularity of electric vehicles will create new opportunities for CNC machining in the automotive industry.

Overall, the future of CNC aluminum machining looks bright. With continued innovation in technology and materials, as well as expanding applications in new industries, this field is poised for significant growth and development. As a leading CNC machining service provider, rapidefficient is well-positioned to take advantage of these trends and continue to deliver high-quality products and services to its customers.

12.3 Recommendation

Rapidefficient is the ideal choice for your CNC machining needs. With its extensive expertise and experience, state-of-the-art equipment, strict quality assurance measures, and a proven track record of customer satisfaction, Rapidefficient stands out as a premier CNC machining service provider.

The company’s expertise is demonstrated by its team of highly skilled professionals who are dedicated to delivering top-notch quality and service. They have in-depth knowledge of the CNC machining process and can handle complex projects with ease and precision. Whether it’s aerospace components with strict tolerances or intricate medical devices, Rapidefficient has the know-how to meet the diverse needs of different industries.

Rapidefficient’s state-of-the-art equipment is another reason to choose them. Equipped with advanced computer numerical control (CNC) systems, the machines can achieve micron-level precision. They are designed for high-speed operation, increasing productivity and reducing production time and costs. The equipment is also known for its durability and reliability, ensuring consistent quality and performance over time. Additionally, the automation capabilities reduce human error and increase production efficiency.

Quality assurance is a top priority for Rapidefficient. The company uses advanced inspection technologies such as coordinate measuring machines (CMMs) to measure the dimensions and geometry of machined parts with extreme accuracy. Visual inspection and surface finish analysis are also crucial parts of the quality assurance process. Rapidefficient conducts regular testing of materials and machining processes and maintains detailed documentation for traceability and quality control purposes.

Customer satisfaction is evident from the testimonials of satisfied customers from various industries. Whether it’s aerospace, automotive, medical, or any other industry, Rapidefficient is committed to providing top-notch CNC aluminum machining services that meet the unique needs of each customer.

In conclusion, if you are looking for a reliable CNC machining service provider that offers precision, efficiency, quality, and customer satisfaction, look no further than Rapidefficient. Choose Rapidefficient for your CNC machining needs and experience the difference.