In the fast-paced world of modern manufacturing, the quest for precision and efficiency is paramount. As industries strive to meet evolving demands and stay competitive, the role of advanced machinery becomes increasingly crucial. Among the myriad of solutions available, the Rapidefficient CNC Machining Center stands out as a beacon of innovation, combining unparalleled precision with exceptional efficiency. This article delves into the fundamentals of CNC machining, the current market landscape, technological advancements, and the unique value proposition that Rapidefficient brings to the table.

The Basics of CNC Machining

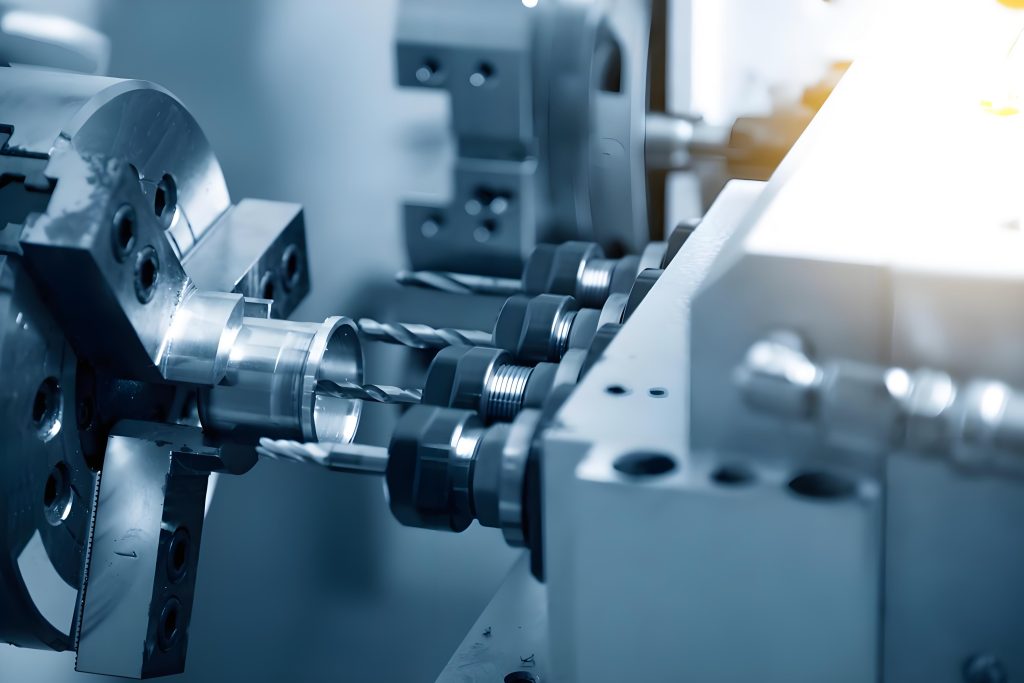

CNC, an acronym for Computer Numerical Control, represents a pivotal shift in manufacturing technology. Unlike traditional machining methods that rely heavily on manual operation, CNC machines utilize computer software to control and automate the cutting and shaping of materials. This transition has revolutionized the industry, offering enhanced accuracy, increased productivity, and reduced labor costs.

At the heart of every CNC machining center lies the control unit, which processes digital data to guide the movement of tools. This data typically originates from CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, allowing engineers to design intricate parts and then seamlessly translate those designs into machine-readable instructions. The result is a seamless workflow from concept to finished product, with minimal human intervention.

Market Landscape: The Rise of Advanced Machining Centers

The global CNC machining market is burgeoning, driven by a myriad of factors. Rapid technological advancements, coupled with an increasing demand for precision-engineered components across various industries, have fueled this growth. From aerospace and automotive to medical and electronics, the need for high-quality, custom-made parts has never been greater.

Moreover, the rise of Industry 4.0, or the fourth industrial revolution, has introduced concepts like smart manufacturing and the Internet of Things (IoT). These innovations have integrated CNC machines into larger, interconnected ecosystems, enabling real-time monitoring, predictive maintenance, and enhanced collaboration between machines and operators. As a result, manufacturers are now capable of achieving unprecedented levels of flexibility, efficiency, and productivity.

Technological Innovations Shaping CNC Machining

The evolution of CNC machining is marked by continuous technological innovations. Here are some of the most significant developments shaping the industry today:

Multi-Axis Machining:

Advanced multi-axis machines can perform complex operations in a single setup, drastically reducing setup times and improving accuracy. This capability is especially critical in the production of intricate parts, where even the slightest deviation can compromise functionality.

High-Speed Cutting (HSC) and Ultra-High-Speed Cutting (UHSC):

HSC and UHSC technologies enable faster material removal rates, leading to shorter cycle times and increased throughput. These advancements are particularly beneficial in the aerospace and automotive industries, where lightweight materials and intricate designs are the norm.

Additive and Subtractive Manufacturing Integration:

The convergence of additive manufacturing (3D printing) and subtractive machining (CNC cutting) is creating hybrid processes that can produce parts with unmatched complexity and precision. This integration allows manufacturers to leverage the strengths of both technologies, optimizing production workflows and expanding design possibilities.

Automated Tool Changing and Material Handling:

Automated systems for tool changing and material handling further enhance the efficiency of CNC machining centers. By minimizing downtime and reducing human error, these systems contribute to higher overall equipment effectiveness (OEE) and improved product quality.

Rapidefficient: Precision and Efficiency in One Center

In the crowded landscape of CNC machining solutions, Rapidefficient emerges as a trailblazer. With a commitment to innovation and excellence, Rapidefficient has designed a series of CNC machining centers that redefine the benchmarks for precision and efficiency.

Precision Engineering

Rapidefficient machines are engineered to achieve micron-level accuracy, ensuring that every part produced meets the strictest tolerances. The use of advanced sensors and feedback mechanisms, combined with precision-ground spindle bearings and high-resolution encoders, contributes to unparalleled repeatability and consistency in part quality.

Efficiency Optimized

Efficiency is a cornerstone of Rapidefficient’s design philosophy. From the streamlined user interface that facilitates quick and error-free programming to the robust construction that minimizes maintenance requirements, every aspect of the Rapidefficient CNC machining center is optimized for maximum productivity. The integration of smart manufacturing principles, such as real-time monitoring and predictive maintenance, further enhances operational efficiency and reduces downtime.

Customizable Solutions

Recognizing the diverse needs of the manufacturing industry, Rapidefficient offers a range of customizable solutions. Whether you require a compact machine for small-batch production or a full-sized center for high-volume manufacturing, Rapidefficient can tailor a solution to meet your specific requirements. This flexibility ensures that you can achieve optimal performance, regardless of your application or production scale.

Real-World Applications: Demonstrating Rapidefficient’s Value

Rapidefficient CNC machining centers have been deployed across a wide range of industries, delivering impressive results. Here are a few examples that highlight the unique value proposition of Rapidefficient solutions:

Aerospace:

In the aerospace industry, lightweight materials and intricate designs are critical. Rapidefficient machines have been instrumental in the production of precision components for aircraft engines, landing gear, and structural assemblies. The high-speed cutting capabilities and micron-level accuracy have enabled manufacturers to achieve significant weight reductions while maintaining structural integrity.

Automotive:

The automotive sector is constantly striving to improve fuel efficiency and reduce emissions. Rapidefficient machines have been pivotal in the development of lightweight components, such as aluminum and magnesium alloy parts, which contribute to overall vehicle efficiency. The ability to produce these parts with tight tolerances and consistent quality has been instrumental in meeting stringent regulatory requirements and customer expectations.

Medical:

In the medical industry, precision is a matter of life and death. Rapidefficient machines have been used to produce surgical instruments, implants, and prosthetics with unparalleled accuracy and reliability. The ability to produce these components in a controlled environment, with strict adherence to quality standards, has earned Rapidefficient a reputation for excellence in the medical manufacturing sector.

Electronics:

The electronics industry demands precision and repeatability in the production of components such as semiconductors, printed circuit boards, and housings. Rapidefficient machines have been instrumental in meeting these demands, enabling manufacturers to achieve tight tolerances and consistent quality across a wide range of materials and applications.

The Future of Rapidefficient CNC Machining

As the manufacturing industry continues to evolve, Rapidefficient remains committed to pushing the boundaries of precision and efficiency. With a focus on continuous innovation and customer-centric solutions, Rapidefficient is poised to lead the charge into the next generation of manufacturing technology.

Future developments will likely include even faster cutting speeds, more intelligent machine control systems, and enhanced integration with other manufacturing processes. Rapidefficient is actively researching and developing these technologies, with the goal of delivering even more powerful and versatile machining centers to the market.

Conclusion: Discover Rapidefficient for Your Manufacturing Needs

In conclusion, Rapidefficient CNC machining centers represent a pinnacle of precision and efficiency in manufacturing. By leveraging advanced technologies and a commitment to innovation, Rapidefficient has created a range of solutions that meet the diverse needs of the modern manufacturing industry.

If you are looking to enhance the precision, efficiency, and productivity of your manufacturing operations, Rapidefficient offers a compelling choice. With a track record of delivering impressive results across a wide range of industries, Rapidefficient is well-positioned to help you achieve your manufacturing goals.

Discover Rapidefficient Today:

For more information about Rapidefficient CNC machining centers and how they can benefit your manufacturing operations, please visit our website or contact us directly. Our team of experts is ready to assist you in selecting the right solution for your application, and we look forward to helping you achieve unparalleled success in your manufacturing endeavors.