Introduction

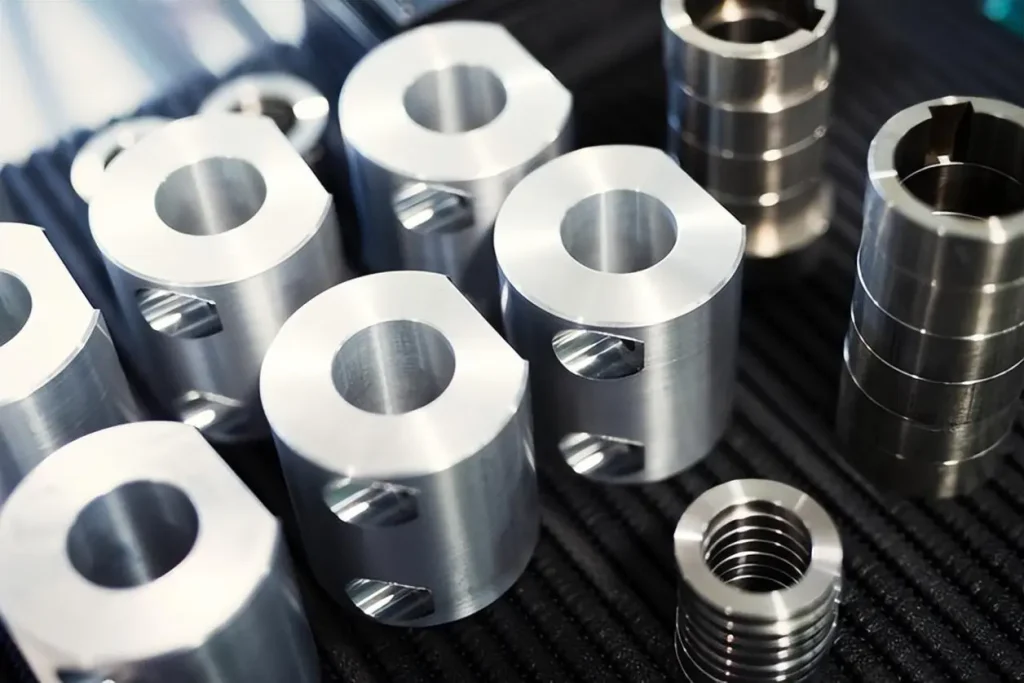

In the highly competitive field of precision parts processing, precision parts processing manufacturers are constantly seeking ways to enhance production efficiency. Higher efficiency not only enables them to meet growing market demands more promptly but also helps reduce costs, thereby strengthening their competitiveness. rapidefficient, with its advanced technology and innovative solutions, holds great potential in this regard. This article will explore practical strategies for precision parts processing manufacturers to improve production efficiency, highlighting the role that rapidefficient can play.

Analyze the current situation

Before delving into improvement strategies, it’s crucial for precision parts processing manufacturers to conduct a comprehensive self – assessment. Many manufacturers today are grappling with issues such as inconsistent product quality. Variations in the quality of precision parts can occur due to a variety of factors, including subpar raw materials, inconsistent machining processes, or insufficient operator training.

Delivery delays are also a common headache. In a supply chain where just – in – time inventory management is the norm, any delay in the delivery of precision parts can disrupt the entire production schedule of downstream manufacturers. For example, if an automotive manufacturer is waiting for precision engine parts, a delay can lead to a halt in vehicle assembly lines, resulting in significant financial losses.

Furthermore, high production costs remain a persistent problem. These costs can be attributed to factors like inefficient use of raw materials, high energy consumption during the machining process, and excessive machine downtime for maintenance. The urgency of improving production efficiency is underscored by the fact that in a global market, customers are becoming increasingly demanding. They expect not only high – quality precision parts but also quick delivery times and competitive prices. Manufacturers that fail to meet these expectations risk losing market share to more efficient competitors. rapidefficient understands these pain points well and can be a game – changer in helping manufacturers overcome these challenges.

Strategies to improve production efficiency

Optimize the production process

One of the primary strategies for precision parts processing manufacturers to enhance production efficiency is to optimize the production process. This involves a meticulous review of each step in the manufacturing process to identify and eliminate any unnecessary or redundant steps. For instance, in the machining of a complex precision part, some traditional processes might involve multiple set – ups that consume a significant amount of time. By streamlining the process and using multi – axis machining centers, manufacturers can reduce the number of set – ups. rapidefficient can assist in this process by providing advanced process planning software. This software can simulate the entire machining process, allowing manufacturers to visualize potential bottlenecks and inefficiencies. It can then suggest optimized tool paths, cutting parameters, and sequence of operations, thereby significantly reducing production time.

Upgrade equipment and technology

Upgrading equipment and technology is a game – changer for precision parts processing manufacturers. Advanced numerical control (NC) machining equipment, such as high – speed milling machines and multi – axis lathes, offers several advantages. These machines can achieve higher machining speeds and accuracies compared to older models. High – speed milling machines can operate at much faster spindle speeds, enabling quicker material removal rates. This not only shortens the machining time for each part but also improves the surface finish of the precision parts.

rapidefficient specializes in providing state – of – the – art equipment and technology solutions. Their advanced NC systems are equipped with high – performance control algorithms that can precisely control the movement of the machine tools. This ensures that the machining process is highly accurate and stable, reducing the occurrence of machining errors. Additionally, rapidefficient’s equipment often incorporates the latest sensor technology. These sensors can monitor the machining process in real – time, detecting any abnormal conditions such as tool wear or excessive vibration. Once detected, the system can automatically adjust the machining parameters or alert the operator, preventing damage to the workpiece and reducing downtime.

Strengthen personnel training

Personnel training is a cornerstone of improving production efficiency. Well – trained operators are essential for the smooth running of precision parts processing operations. They need to have a deep understanding of the equipment they operate, as well as the machining processes involved. For example, an operator who is proficient in programming NC machines can write more efficient code, reducing machining time and improving part quality.

Training should cover a wide range of aspects, including technical skills, quality control, and safety procedures. Technical training can include hands – on operation of new equipment, learning advanced machining techniques, and understanding the principles of precision measurement. Quality control training ensures that operators are aware of the importance of maintaining high – quality standards throughout the production process. Safety training, of course, is crucial to prevent accidents in the workplace.

rapidefficient offers comprehensive training programs for personnel. Their training courses are designed by industry experts and are tailored to the specific needs of precision parts processing manufacturers. These courses can be delivered on – site or online, providing flexibility for manufacturers. In addition to theoretical knowledge, the training programs also emphasize practical skills, with participants having the opportunity to operate real – world equipment and solve actual production problems. By investing in personnel training with the support of rapidefficient, manufacturers can significantly improve the skills and productivity of their workforce.

Improve management level

A high – level management system is vital for precision parts processing manufacturers to improve production efficiency. Establishing a scientific management system, such as implementing a well – organized production planning and control system, can ensure that all production activities are coordinated and efficient. For example, a good production planning system can accurately schedule the production of different parts, taking into account factors like equipment availability, raw material supply, and customer delivery deadlines.

Optimizing resource allocation is another key aspect of management. This includes effectively managing human resources, equipment, and raw materials. By ensuring that the right people are assigned to the right tasks, and that equipment is properly maintained and utilized, manufacturers can avoid bottlenecks and idle time.

rapidefficient can play a significant role in helping manufacturers improve their management levels. They can provide management software solutions that integrate production planning, quality control, and inventory management. This software allows managers to have a real – time overview of the entire production process, enabling them to make informed decisions promptly. For example, if there is a sudden change in customer demand, the management software can quickly recalculate the production schedule and adjust resource allocation accordingly, ensuring that the manufacturer can respond to the change efficiently.

The value of rapidefficient in the CNC machining market

rapidefficient has emerged as a highly valuable player in the CNC machining market. One of its most prominent features is its high precision. In precision parts processing, achieving tight tolerances is crucial. For example, in the aerospace industry, where components need to withstand extreme conditions, the precision requirements are extremely high. rapidefficient’s equipment can consistently achieve micron – level precision, ensuring that parts fit together perfectly. This not only improves the performance of the final products but also reduces the need for rework, saving both time and cost.

The high – speed capabilities of rapidefficient are also a game – changer. High – speed machining allows for faster material removal rates. In a manufacturing scenario where a large number of precision parts need to be produced within a short time frame, such as in the electronics industry for components like circuit boards, rapidefficient’s high – speed machines can significantly shorten the production cycle. This enables manufacturers to meet tight delivery schedules and gain a competitive edge in the market.

Stability is another key aspect of rapidefficient’s offerings. In the machining process, stability ensures that the quality of the parts remains consistent throughout production. For instance, in the automotive industry, when manufacturing engine parts, any instability in the machining process could lead to parts with inconsistent quality, which could in turn affect the performance and reliability of the engines. rapidefficient’s stable equipment and advanced control systems minimize vibrations and fluctuations during machining, guaranteeing that each part produced meets the highest quality standards.

A real – world example of rapidefficient’s impact can be seen in a medical device manufacturing company. The company was struggling to meet the growing demand for its precision – made surgical instruments while maintaining high quality. After adopting rapidefficient’s CNC machining solutions, they were able to increase their production capacity by 30% within three months. The high precision of the equipment reduced the defect rate from 5% to less than 1%, and the stable operation of the machines meant fewer machine breakdowns, resulting in significant cost savings.

Conclusion

In conclusion, precision parts processing manufacturers can significantly enhance their production efficiency through a combination of strategies. Optimizing the production process, upgrading equipment and technology, strengthening personnel training, and improving the management level are all essential steps. rapidefficient, with its high – precision, high – speed, and stable CNC machining solutions, offers a wealth of opportunities for manufacturers. By leveraging rapidefficient’s advanced technology and services, manufacturers can not only improve production efficiency but also enhance product quality, reduce costs, and ultimately gain a competitive edge in the global precision parts processing market. It’s time for precision parts processing manufacturers to take action and explore how rapidefficient can transform their operations.