Why is CNC part processing so expensive? It is related to the processing quantity, processing time, material cost, setup time, and other design factors.

Processing Quantity

The prices for individual parts and in – batch production are definitely different.

Processing Time

The longer the processing time for aluminum alloy parts, the higher the CNC cost. Processing time is the main driving factor of CNC cost.

Material Cost

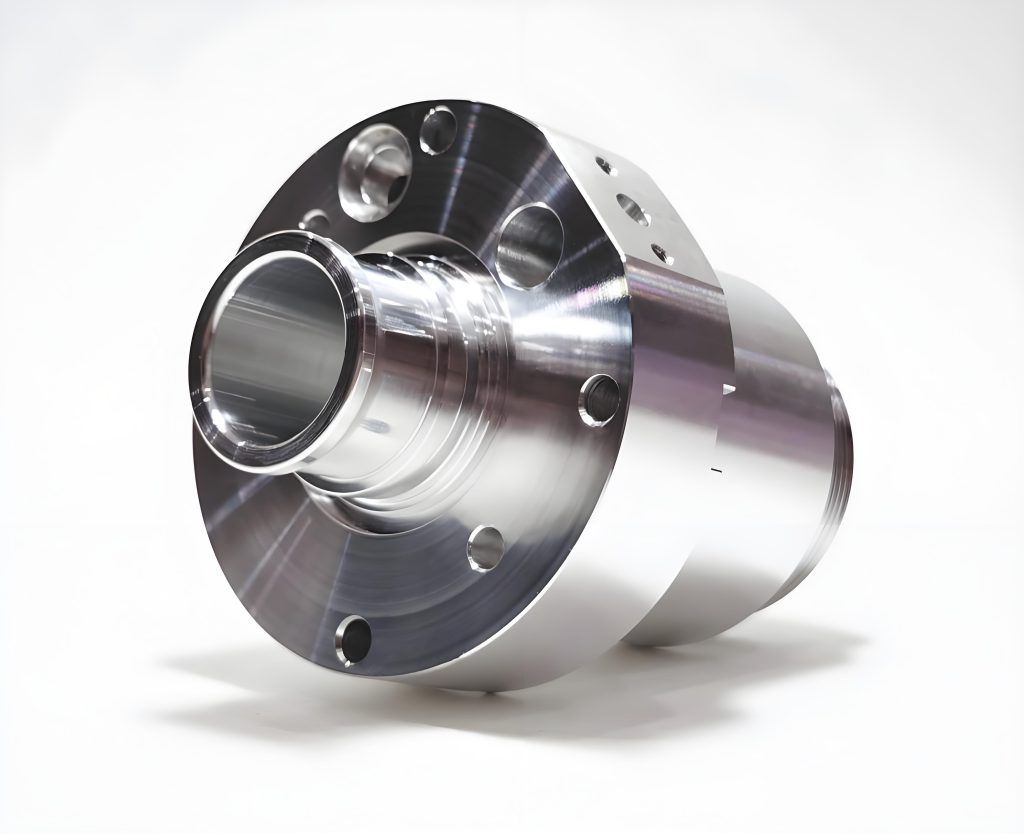

The cost of blank materials is an important part of CNC processing cost. Material costs can be reduced by optimizing the design to use standardized blanks as much as possible and reducing waste. Currently, aluminum alloy is one of the raw materials with a relatively moderate price and good machinability.

Setup Time

When CNC part processing is on a small scale, the preparation of the geometric model and the planning of the processing process seriously affect the CNC cost of aluminum alloy part processing. This part of the cost is a fixed cost and can be spread out through large – volume production.

Other Design Factors

When the design of CNC part processing has special requirements (such as precise tolerance requirements and thin – wall design), special tools, more precise quality control, lower processing speeds, and more complex processing steps are required, all of which will seriously affect the CNC cost.