Overmolding is a unique manufacturing process. It involves combining two or more materials into one product. This technique offers various advantages that can enhance product quality and performance. Let’s explore the key benefits of overmolding.

Improved Ergonomics

One significant advantage of overmolding is improved ergonomics. Manufacturers often use softer materials for the outer layer. This design enhances the grip and comfort of products. For example, overmolded handles on tools and appliances provide a secure hold. This feature reduces hand fatigue and increases user satisfaction.

Enhanced Aesthetics

Overmolding also allows for creative design possibilities. Manufacturers can use different colors and textures to create visually appealing products. The combination of materials can add depth and style. This advantage is particularly useful in consumer goods, where aesthetics play a crucial role in attracting customers.

Reduced Assembly Time

Another benefit of overmolding is the reduction in assembly time. By combining materials in a single process, manufacturers eliminate extra assembly steps. This efficiency leads to lower labor costs and faster production times. As a result, companies can respond quickly to market demands and increase overall productivity.

Cost-Effectiveness

Overmolding can be cost-effective in the long run. Although the initial investment in molds may be higher, the savings in labor and production time often outweigh these costs. Additionally, overmolding reduces the number of individual components required. This simplification of the supply chain can lead to further savings.

Improved Durability

Durability is another key advantage of overmolding. The combination of materials can enhance the strength of the final product. For instance, the rigid core provides structural integrity, while the softer outer layer offers impact resistance. This characteristic is vital in industries like automotive and electronics, where products must withstand wear and tear.

Better Sealing and Protection

Overmolding can improve the sealing and protection of components. The soft material can create a barrier against moisture, dust, and other contaminants. This feature is especially important in electronics, where exposure to the elements can damage sensitive components. By using overmolding, manufacturers can enhance the longevity and reliability of their products.

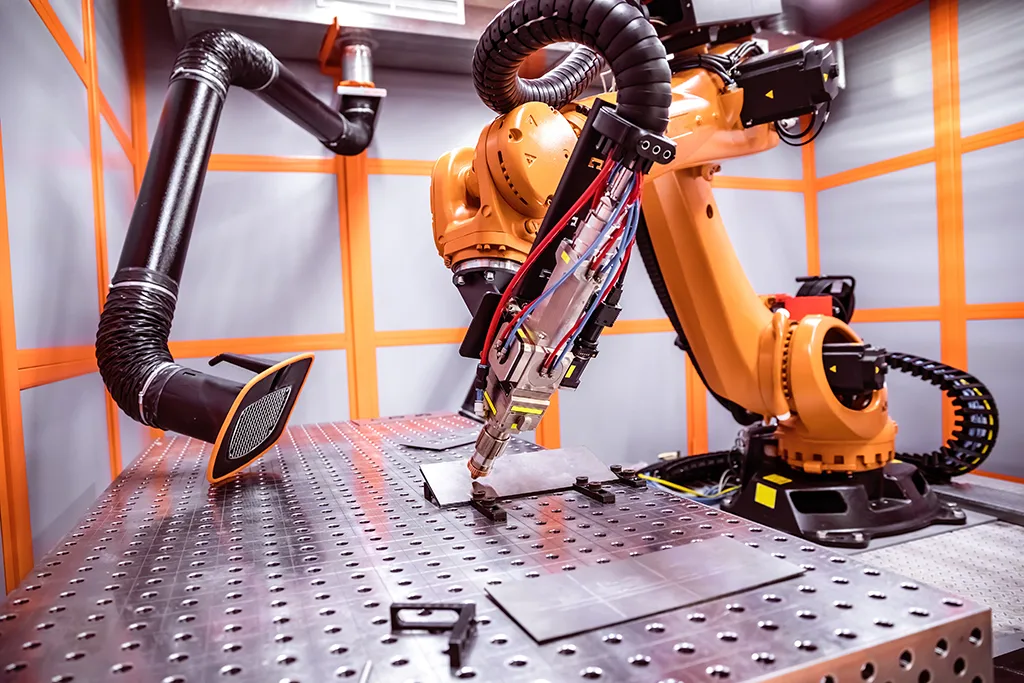

Versatility in Applications

Overmolding is highly versatile and can be applied across various industries. From consumer electronics to medical devices, its benefits are evident. Manufacturers can tailor the process to meet specific requirements, such as improved grip or enhanced safety features. This versatility allows companies to innovate and stay competitive.

Customization Options

Another advantage of overmolding is the potential for customization. Manufacturers can create unique products that meet specific customer needs. By using different materials and designs, companies can differentiate themselves in the market. This ability to customize enhances customer satisfaction and loyalty.

Environmental Benefits

Overmolding can also contribute to environmental sustainability. By reducing the number of parts and materials required, manufacturers can minimize waste. Additionally, the use of eco-friendly materials in overmolding is on the rise. This shift toward sustainability aligns with consumer preferences and regulatory requirements.

Conclusion

In summary, overmolding offers numerous advantages that can significantly improve product quality and performance. From enhanced ergonomics and aesthetics to cost-effectiveness and durability, the benefits are compelling. As industries continue to evolve, overmolding will play an increasingly important role in manufacturing.

By understanding the advantages of overmolding, businesses can leverage this technique to create superior products. Ultimately, adopting overmolding can lead to higher customer satisfaction and a competitive edge in the market. Companies that embrace this innovative process will be well-positioned for future success.