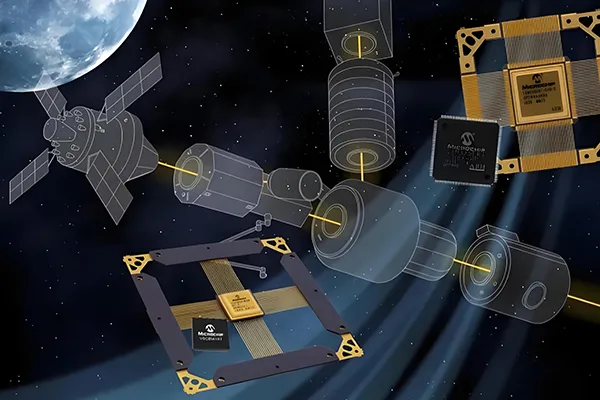

Aerospace Prototyping

Rapidefficient provides specialized manufacturing solutions to the aerospace industry, The industry’s focus on quality, Performance and durability requirements are very high. Our precision-crafted components, Advanced assembly structures and customized components, Help aerospace engineers, OEMs and suppliers meet industry’s stringent standards.

Extremely fast innovation

Excellent and efficient

Unique charm

Provide agile and high-quality rapid prototyping solutions, Covers industry, medical, transportation, Energy and environmental protection and other professional fields. From initial idea to finished part, We have state-of-the-art facilities and deep expertise to achieve the most challenging designs.

Producing quality aerospace component prototypes is a business that depends on precision, Quality and strict compliance with standards mission. for a long time, We are dedicated to aerospace prototyping, Accumulated professional experience in producing various types of aerospace components, whether simple or complex. 3EAP implements extensive quality inspections and testing, To ensure that all components produced must satisfy customers, and undergoes the most stringent certification and testing processes. Request a quote for your design or contact us, Find out how we can work with you in aerospace.

Can we still make it?

We can also make these

Rapidefficient provides comprehensive manufacturing processes for consumer product prototypes and production parts

CNC machining

By using CNC numerical control processing technology, We can create prototypes and production parts in a variety of complex shapes.

Die casting

We provide small batch test molds and high-volume production molds.

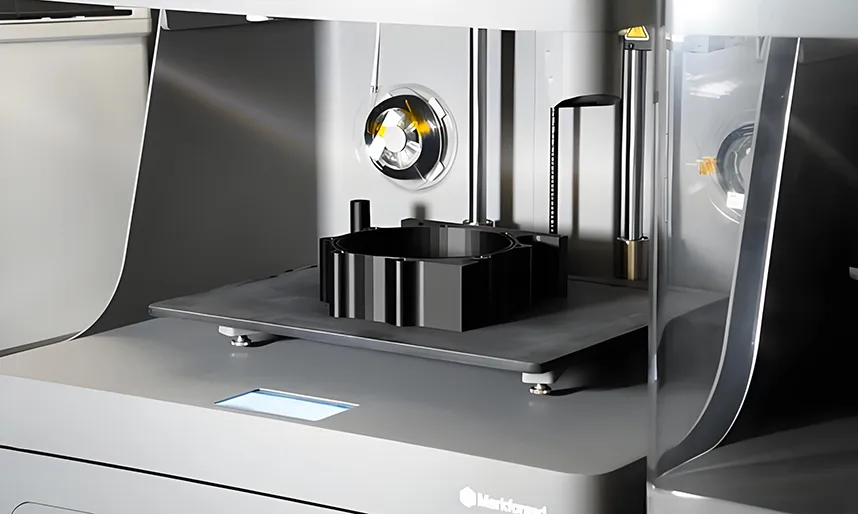

3D print

We provide 4D printing services for specialty material parts using a range of advanced additive manufacturing technologies.

Promising aerospace manufacturing

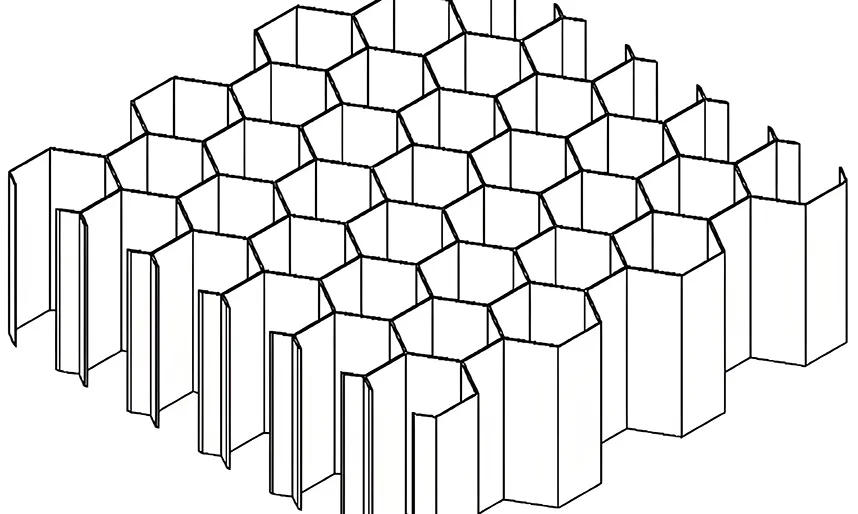

When building a spacecraft, Every bit of weight can affect a spacecraft’s optimal performance. We use advanced 3D printing technology, By creating a partially hollow honeycomb structure inside, Can significantly reduce component weight, This technique could be applied to create honeycomb structures within components such as metal spacecraft components or plastic cabin bulkheads.

Many aerospace vehicle parts can be processed by CNC, e.g. engine parts, landing gear components, electronic components, Bulkheads and fuselage skins. When the work involves producing critical end-use components, Precision machining requires the use of high-quality multi-axis machining centers.

Parts suitable for aerospace CNC machining are typically low-volume components that require high strength and fine features. Machining can also be used to repair or improve existing components, Add detailed features or add engraved text information (e.g. batch number). Some components may only be post-processed after forging or drawing.

Aerospace part display

for a long time, We have accumulated rich experience, Allowing us to handle any aerospace mission. Below is a showcase library of aerospace models and production components that we provide to our global customers.

A wide range of materials are available for all our manufacturing processes, Listed below are some common choices for consumer product projects.

Available in a variety of high level surface treatments. We list just some of the common surface treatment options. More surface treatment options for custom parts in the consumer products industry.

FAQ

Is Rapidefficient Manufacturing ISO certified?

Yes, Rapidefficient Manufacturing is an ISO9001-2015 certified manufacturer. No matter what kind of project or every customer, We all manufacture parts to high standards.

Can samples be provided?

For some manufacturing processes (such as die-casting), We can provide initial samples of your parts, Then provide subsequent samples according to demand.

How long will it take to get my parts?

We can fulfill orders quickly, But the delivery time depends on some factors, such as manufacturing processes, Order quantity and part complexity. The fastest way to CNC machine parts is 4 sky, 3The fastest way to 3D print parts is just 2 sky, The mold manufactured through rapid tooling is the fastest and only needs 4-6 sky.

I want to protect my intellectual property – are my designs safe?

Rapidefficient manufacturing takes privacy and security seriously, and will happily sign a non-disclosure agreement (NDA) upon your request, Let you feel confident about your intellectual property rights.