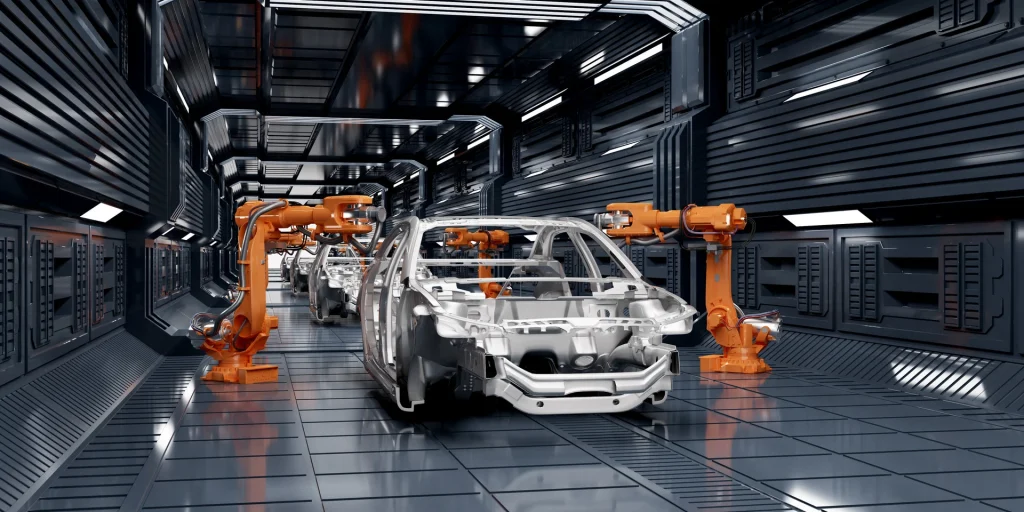

Express Solution for Auto Parts Manufacturing

Metal and plastic custom parts for the automotive industry with 3D printing, CNC machining, sheet metal, vacuum casting, and injection molding. Instant online quotation and lead time from 3 days.

Online instant pricing & Free DFM

Rapid prototype as far as 2 days

Tight tolerance control into +/- 0.01mm

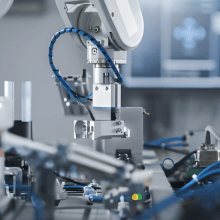

On-demand manufacturing in the Automotive Industry

We provide unrivaled speed and efficiency for automotive industry prototyping and production.

Powerful Capabilities

Our powerful manufacturing capabilities are the cornerstone of our success.

Instant Quotation

Get accurate and timely quotes with our innovative instant quotation system.

High Precision Parts

Our advanced manufacturing techniques and cutting-edge technology allow us to produce intricate.

Fast Cycle Time

At RapidEfficient, we pride ourselves on delivering fast cycle times that keep you ahead of the competition.

Solutions for Automotive Products

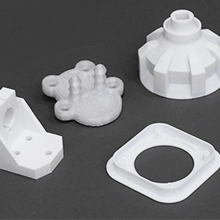

Prototype

Accelerate early design turnaround with a variety of 3D printing and vacuum casting options.

Verify Function and Material Vacuum casting in different Materials

Production Verification Test

Trial production in small batches to verify the overall performance of the product.

Highest Precision Requirements

Structural Components

Mass production

Mass Production of Plastic Parts

Highest Precision Requirements

Automotive Parts Applications

Rapid prototyping

Supply of production accessories

Volume manufacturing support

Cooperation With the Top Automotive Companies Worldwide

From custom designs to unique color and material options, RapidEfficient’s innovative manufacturing model gives you an advanced competitive edge.

- Electric vehicles

- Autonomous vehicle sensors

- Intermediary & replacement parts

- Electric bikes and scooters

- Infotainment systems

- Utility vehicles

- Commercial vehicles

- Manufacturing line jigs & fixtures

- Autonomous driving components

- EV battery testing components

Why Choose RapidEfficient

Unleashing Our Company's Strengths

RapidEfficient is a one-stop solution platform from prototyping, R&D to mass production. Utilizing our instant quoting platform and comprehensive supplier network, you can quickly obtain design validation and accelerate your product launch.

Production capacity

Strict quality control

Provide professional quality inspection report

- Standard Inspection with Formal Report

- CMM Inspection with Formal Report

- Source Material Certification

Instant quote online

Recognized by Many Large Enterprises

- Consumer electronics companies

- Personal and household products manufacturers

- Automobile OEMs

- Automotive Part Companies

- Aircraft OEMs

- Commercial aviation companies

- Healthcare providers

- Diagnostics equipment manufacturers

- Industrial robot manufacturers

- Heavy Machinery Manufacturers

Gallery of Automotive Parts

UTR Imagine Black

Technology:3D printing – SLA

UTR Imagine Black

Technology:3D printing – SLA

UTR Imagine Black

Technology:3D printing – SLA

UTR Imagine Black

Technology:3D printing – SLA

UTR Imagine Black

Technology:3D printing – SLA

UTR Imagine Black

Technology:3D printing – SLA

FAQ's

How is quality ensured in injection molding for automotive manufacturing?

Quality in injection molding for automotive manufacturing is ensured through rigorous quality control, precise process parameter control, proper mold design and maintenance, material selection, and testing. Advanced technologies and regular maintenance are employed to maintain consistent part quality.

How is 3D printing used for rapid iteration in automotive design?

What are the differences between sheet metal fabrication and injection molding in automotive?

How do CNC machining and 3D printing collaborate in automotive manufacturing?

Our Services Cover Multiple Other Industries

Automotive

Consumer Electronics

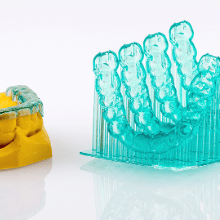

Medical and Dental

Industrial Machinery

Aerospace & Aviation

Robotics

3D Printing for Automotive

3D Printing for Medical and Dental

3D Printing for Cultural Creativity