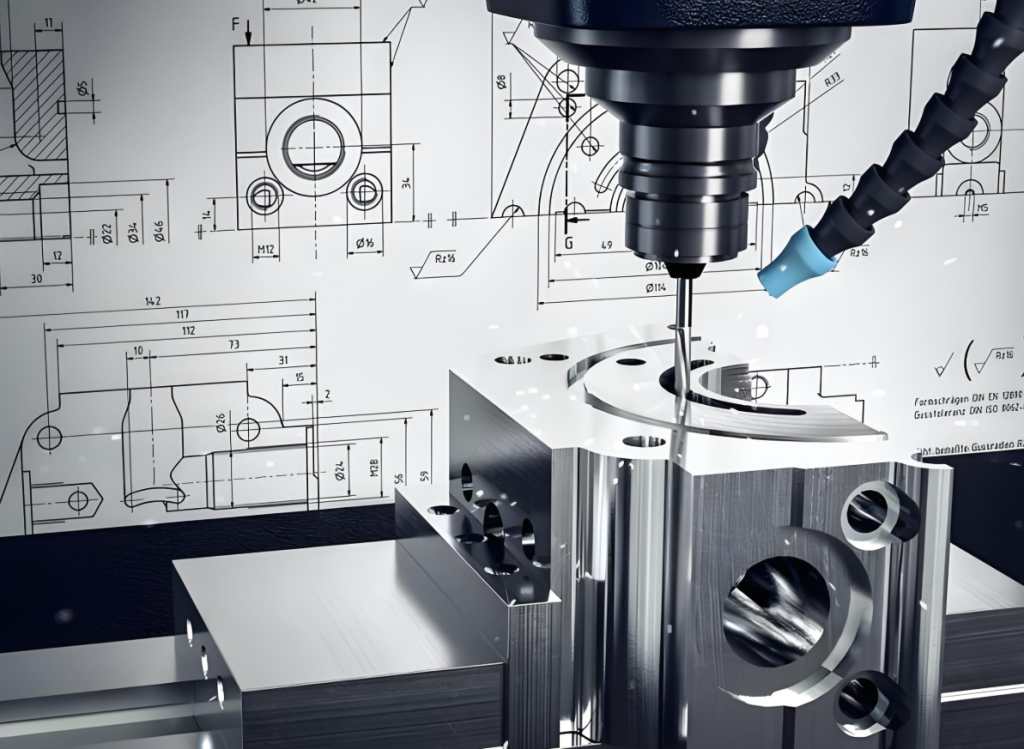

In the grand narrative of “Made in China 2025”, CNC (Computer Numerical Control) machining has always been an irreplaceable core driving force in the field of precision manufacturing. It has transcended a single technology and has become a key yardstick for measuring a country’s high-end manufacturing capabilities. The industry is undergoing profound changes, with technological iteration and market pattern restructuring intertwined, jointly painting a picture of future manufacturing.

1. Five-axis linkage: from “luxury” to “must-have”, a revolutionary breakthrough in precision machining

Five-axis machining technology is becoming popular at an unprecedented speed, completely subverting the machining logic of complex curved surfaces and special-shaped structural parts. Its core advantages are:

Efficiency Jump: Complete multi-sided processing in one clamping, reduce repeated positioning errors, and increase efficiency by 20%-30%.

Precision Leap: Complex Spatial Angle Compensation Capability (RTCP Function) ensures micron-level accuracy, meeting stringent requirements such as aero engine blades and precision medical implants.

Cost Optimization: Significantly reduces the cost per piece by reducing fixtures, processes, and manual interventions.

Design Freedom: Engineers break free from the constraints of traditional craftsmanship and achieve more lightweight, integrated innovative designs.

Industry case: A precision mold company in Shenzhen introduced domestic high-end five-axis machine tools, successfully processed magnesium alloy medical endoscope components with a wall thickness of 0.1mm and complex curved surfaces, with a yield rate of more than 95%, becoming a core supplier of international giants.

2. Smart factory: CNC from “stand-alone intelligence” to “system intelligence”

CNC machines are no longer information islands and are deeply integrated into the Industrial Internet of Things (IIoT) ecosystem:

Data-driven decision-making: Real-time collection of spindle load, vibration, temperature, tool wear, and other data, using AI algorithms to predict equipment failures and optimize process parameters.

Cloud collaboration: Remote issuance of processing programs, real-time status monitoring, and intelligent scheduling of production capacity to achieve cross-factory and cross-regional collaborative production.

Digital twin application: Simulate and verify the machining process in a virtual environment, greatly shortening the trial production cycle and reducing the cost of physical trial and error.

Industry Dynamics: A leading auto parts factory in the Yangtze River Delta has built a “black light workshop”, hundreds of CNC equipment are interconnected through 5G private network, key processes are unattended, the overall equipment comprehensive efficiency (OEE) has been increased to 85%, and the order delivery cycle has been shortened by 40%.

3. Additive Manufacturing (3D Printing): From “Disruptor” to “Collaborator”

Metal 3D printing technology does not replace CNC, but forms a powerful complementary effect with it:

Rise of hybrid manufacturing: 3D printing completes the near-net forming of complex blanks, and CNC precision machining ensures critical dimensions and surface quality, achieving both efficiency and precision.

Repair and Remanufacturing: CNC finishing 3D prints or damaged high-value parts, such as turbine blades, to extend life and reduce costs.

Conformal cooling mold: 3D printing manufacturing special-shaped cooling water channel that cannot be achieved by traditional processes, CNC machining mating surface, significantly improving injection molding efficiency and quality.

Technological frontier: International leading machine tool manufacturers have launched composite machining centers that integrate metal 3D printing and five-axis milling to achieve “one-step” manufacturing of complex parts, bringing revolutionary changes to the aerospace and medical fields.

4. Emerging markets driven: new energy and semiconductors have become new engines of growth

Under the fluctuation of demand for traditional automobiles and general machinery, the CNC industry has ushered in an explosion in two major fields:

New energy vehicles: The demand for precision parts for motor housings (high-precision requirements), battery trays (processing of super-large structural parts), and electronic control systems has surged, promoting the development of high-speed, high-rigidity, and large-stroke CNC equipment.

Semiconductor equipment: Core components such as wafer transfer manipulators, vacuum chambers, and optical component bases require nano-level surface roughness and sub-micron shape and position tolerances, giving rise to the demand for ultra-precision machining technology and equipment.

Market observation: Leading CNC companies in China have laid out new energy special models, and the “gantry high-speed machining center” developed by a company specializes in battery pallet processing, with an efficiency increase of 50% compared with traditional solutions, quickly seizing the market.

Conclusion: The future has come, only change remains unchanged

The CNC machining industry is standing at the crossroads of technology integration and industrial upgrading. The four major trends of five-axis popularization, intelligent interconnection, additive integration, and emerging market drive do not exist in isolation, but are intertwined and reinforce each other, jointly promoting the manufacturing industry to make a leap in the direction of higher efficiency, higher precision, higher flexibility, and more sustainability.

Technology has no end, only continuous innovators can grasp the core voice in this new era of precision manufacturing and define future manufacturing standards. For practitioners, understanding trends, embracing change, and deepening technology are the only ways to seize the opportunities of the times.