Precision machining services

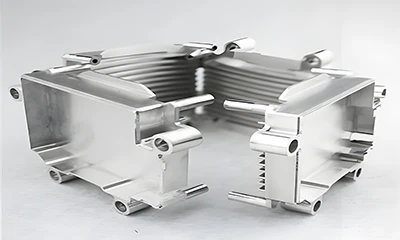

Our precision machining services are dedicated to manufacturing high quality precision machined parts that meet and exceed customer expectations.

One-off Precision machining services prototype

Our Precision machining services capabilities

There are many reasons to choose Rapidefficient Precision Machining Services. It has advanced CNC equipment, Ensure high-precision processing, Can meet complex design needs. Professional technical team strictly controls every aspect, Ensure product quality is stable and reliable. Efficient processing procedures shorten production cycle, Meet customer urgent order needs. at the same time, Focus on customer needs, Provide personalized solutions, With quality service and reasonable price, Create higher value for customers, Whether it is aerospace, Medical equipment or electronic equipment and other fields, All are ideal choices, Help customers stand out in market competition.

CNC numerical control precision machining is a method of high-precision machining using computer numerical control (CNC) technology.

In traditional machining, Workers need to manually operate machine tools, Machine parts by adjusting the position and movement of the tool. Not only is this approach inefficient, And the accuracy is difficult to guarantee. CNC precision machining controls the movement of the machine tool through pre-written programs, thereby achieving high precision, Highly efficient processing.

CNC precision machining usually uses CNC machine tools, These machine tools feature high-precision motion control systems and tooling systems, Very precise machining possible. CNC machines can process a variety of materials, including metal, plastic, Ceramics etc., And can process very complex shapes.

The main advantages of CNC precision machining include:

1. High precision: Very precise machining possible, Accuracy can reach micron level.

2. High efficiency: Can realize automated processing, Greatly improved production efficiency.

3. flexibility: Can process parts of various shapes and materials, Highly flexible.

4. Stable quality: Since the machining process is controlled by the program, So the processing quality is very stable.

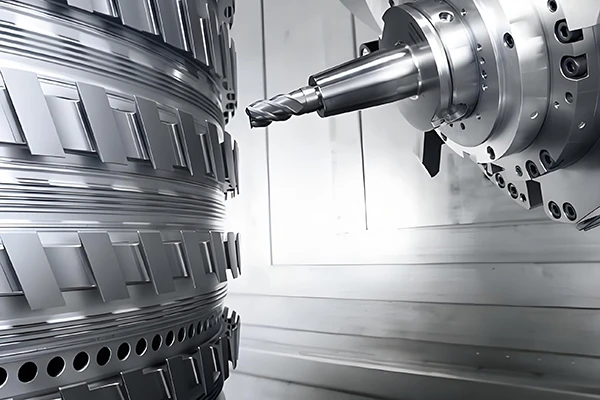

Aerospace parts processing

Can process aircraft engine blades with high precision, Turbine disc and other key components. With advanced equipment and exquisite craftsmanship, Can ensure dimensional accuracy and surface quality of complex curved surfaces, Meet the stringent requirements for safety and reliability in the aerospace industry.

Processing aircraft structural parts, such as fuselage frame, Wing connectors, etc., Guaranteeing high strength and lightweight at the same time, Achieve high-precision assembly requirements.

Medical device precision parts processing

Manufacturing high-precision medical implants, such as artificial joints, Dental implants, etc., Strictly control processing accuracy and surface roughness, Ensure good compatibility with human tissue and long-term stability.

Processing key components of medical instruments, such as microscope components, Surgical instruments, etc., Meets the high demands for precision and hygiene standards in the medical industry.

Electronic equipment precision housing processing

For mobile phone, Precision casings for tablets and other electronic devices. Through high-precision processing, Achieve thin, light and beautiful design, At the same time, it ensures perfect cooperation between the outer shell and the internal components.

Processing of radiators for electronic equipment, Shielding covers and other components, Ensure good heat dissipation performance and electromagnetic shielding effect.

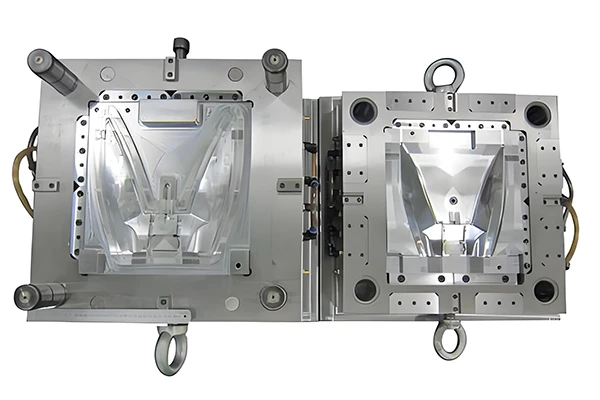

Precision mold processing

Manufacturing high-precision injection molds, Stamping molds, etc., Precisely control the dimensional accuracy and surface quality of the mold, Improve the service life of the mold and the molding quality of the product.

Machining complex die-casting molds, meet car, Demand for large precision molds in home appliances and other industries.

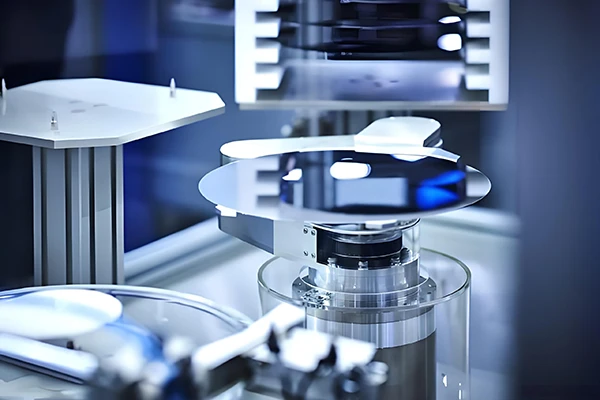

Optical component processing

Processing of high-precision optical lenses, prism etc., Strictly control surface roughness and shape accuracy, Ensure the stability and accuracy of optical performance.

Manufacture of precision components for optical instruments, such as microscope objective lens, Telescope barrel, etc., Meet the requirements of the optical industry for high-precision processing.

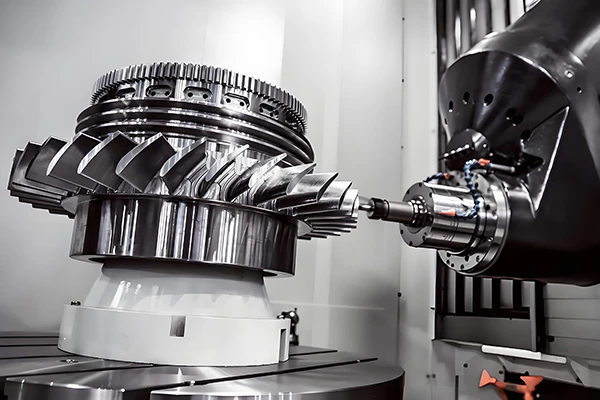

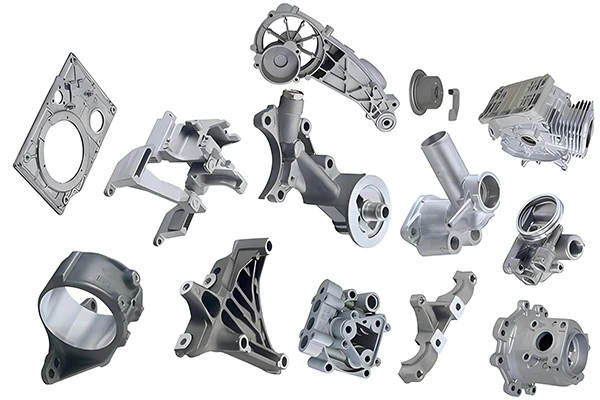

Automobile precision parts processing

Processing of automobile engine cylinder blocks, Cylinder head and other key components. Ensure high-precision dimensional fit and good sealing, Improve engine performance and reliability.

Making gears for automobile transmissions, Shafts and other parts, Meet the requirements of the automotive industry for high strength and precision.

In order to let you intuitively feel our CNC machining strength, Here are some of our past project results, and demonstration components carefully designed by professional engineers. Our team has demonstrated exceptional flexibility with all types of CNC machined components. so, If you are looking for a Precision machining services company for your project, Then you don’t have to run around anymore!

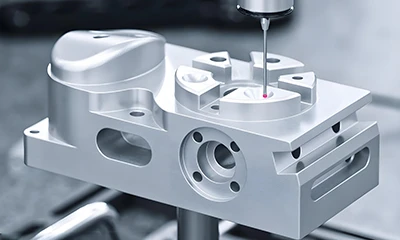

Your parts will be manufactured and inspected in our state-of-the-art in-house facilities, Includes precision three-axis, four axis, Five-axis machining center, CMM measuring instrument, 33D scanner, etc.

You will get a quick quote reply within 24 hours, 95%On-time delivery and parts shipped in 7 days or less.

From first prototype CNC machining inspection to 100% part final inspection, We ensure our quality inspection is as accurate as our CNC machining process.

We can produce high-precision, complex parts, Dimensional tolerance ±0.01mm, Geometric tolerance 0.01mm, Minimum processing radius R0.1mm, Machined surface roughness Ra0.2μm. We are also often challenged with optical parts with precision detail orientation.

Our CNC precision machining for volume production ensures repeatable and consistent results. You can get 1 to 10000 pieces of the same high quality parts, No need to compromise on cost or quality.

Reasonably design the structure of the part to reduce stress concentration during processing, thereby improving part accuracy.

Heat treating materials to increase strength and reduce internal stress, Control machining processes to reduce or eliminate machining defects.

Upgrading to a 5-axis machine or a 3+2 configuration is one of the fastest ways to increase CNC machining speed and accuracy.

Reasonably design the structure of the part to reduce stress concentration during processing, thereby improving part accuracy.

Properly designed tooling fixtures can ensure repeatability of machining accuracy, and improve processing efficiency.

Upgrade and maintain machines, And ensure that the machine tool has a flat, Stable and sturdy base, to absorb vibration.

Correct selection and use of knives, Essential for improving dimensional stability in processing.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential.

What are the tolerances for manufacturing parts?

The tolerance range of sheet metal processing parts is ±0.2-0.3mm.

What are the quality standards for small batch production services?

We have strict quality control standards, To ensure the quality of small batch production. first, We inspect incoming materials to ensure material quality. Secondly, We inspect and test the production process, To ensure you get quality parts that exceed your expectations. third, We can provide certificates of conformity for all materials.

What is the cost of efficiently machined parts?

Our engineering and sales teams will provide one-on-one quoting support for your project. Normally, for similar parts, CNC lathe machining costs are 15% lower than 3-axis CNC milling. compared to this, 5The cost of shaft machining has increased, 5The processing cost of axis-linked CNC milling is usually more than 20% higher than that of 3+2 machine tools, About twice as long as a standard 3-axis mill. For the most cost-effective CNC machined parts, Recommended for larger production runs, To spread the cost of machine setup.

What information do you need to provide a quote?

To provide meaningful offers, We need the following information:

We accept 2D and 3D CAD data in any format, Includes STP, IGES, X_T, DWG, PDF, STL;

expected quantity, Processing technology, and the required raw materials;

Any necessary secondary operations, Includes finishing specifications, heat treatment, Oxidation or electroplating, etc.;

Any applicable customer specifications, For example, first article inspection, PPAP requirements and required external process certificates;

any other useful information, Such as target price or desired delivery time.

CNC numerical control machining, i.e. computer numerical control processing, Plays a pivotal role in modern manufacturing, Its main advantages are as follows:

High precision machining:

CNC machining enables extremely high precision, Tolerances can be strictly controlled within a very small range, Accuracy of ±0.01 mm or better is typically achieved. Whether it is a complex three-dimensional surface, Or a fine microstructure, can be processed accurately. This results in manufactured parts with a high degree of consistency and reliability, Greatly improved product quality.

Efficient production:

1. High degree of automation: Once programming is complete, The machine tool can automatically run according to the predetermined program, No need for frequent manual intervention. This not only reduces the labor intensity of operators, It is also possible to achieve continuous, Stable processing, Greatly improved production efficiency.

2. Fast processing speed: CNC machine tools can be customized according to different processing requirements, Quickly adjust parameters such as cutting speed and feed rate, To achieve the best processing effect. Compared with traditional processing methods, Processing time can be significantly reduced.

High flexibility:

1. Suitable for processing a variety of parts: for different shapes, Dimensions and materials of parts, CNC machining can be easily handled. Whether it is a simple geometric shape or a complex special-shaped structure, can be programmed to achieve precise processing.

2. Easy to modify and adjust: If design changes need to be made to the part, Just modify the program, No need to re-make tooling fixtures, etc., Greatly save time and cost.

Stable quality:

Since the machining process is precisely controlled by computers, Reduces the impact of human factors on processing quality. Parts produced are highly consistent every time, Ensure the stability of product quality. at the same time, CNC machines also enable real-time monitoring and feedback, Find and correct problems during processing in a timely manner, Further improved processing quality.

Complex processing capabilities:

CNC machining can realize multi-axis simultaneous machining, Able to complete complex shape processing tasks that are difficult to complete with traditional processing methods. For example, Complex components in the aerospace industry, Car engine cylinder block, etc., are inseparable from the powerful capabilities of CNC machining.

Although CNC machining has many advantages in modern manufacturing, But it also faces some major challenges:

High cost investment:

1. Equipment acquisition cost is high: CNC machines themselves are expensive, Especially high precision, Advanced machine tools with multi-axis linkage, Its purchase cost may be as high as millions or even tens of millions of dollars. This is a huge investment for SMEs.

2. High maintenance costs: In order to ensure the normal operation and accuracy of machine tools, Requires regular maintenance and upkeep, Includes replacement tools, Lubrication system maintenance, Accuracy calibration, etc., These require a large investment of capital and manpower.

High technical requirements:

1. Programming is complex: CNC machining requires professional programmers for programming. The programming process requires more than just mastering complex programming languages and algorithms, You also need to have an in-depth understanding of the processing technology, to ensure program correctness and efficiency. This requires high technical level of programmers.

2. High skill requirements for operators: Operators of CNC machine tools require professional training, Be familiar with the operation methods of machine tools, Maintenance knowledge and safe operating procedures, etc., at the same time, Operators also need to have certain problem-solving skills, Able to handle various emergencies in a timely manner during processing.

Complex processing technology:

1. Difficulty in tool selection: Different materials and processing requirements require the selection of different tools, The choice of cutting tools directly affects the processing quality and efficiency. Correct selection of tools requires consideration of material hardness, cutting performance, Processing accuracy and many other factors, This places high demands on processing technology.

2. Difficulty optimizing processing parameters: cutting speed, Feed amount, Optimization of processing parameters such as cutting depth needs to be adjusted according to specific processing tasks, To achieve the best processing effect. This requires extensive processing experience and expertise, Otherwise, the processing quality may be reduced, Problems such as increased tool wear.

Market competition is fierce:

With the development of manufacturing, Competition in the CNC machining market is becoming increasingly fierce. Enterprises not only have to face competition from domestic peers, We also have to deal with challenges from the international market. in this case, Enterprises need to continuously improve their technical level and service quality, to reduce costs, Improve efficiency, Enhance market competitiveness.

Our CNC machining services have been praised by global customers from different fields. We supply CNC machining components to a variety of industries, Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.