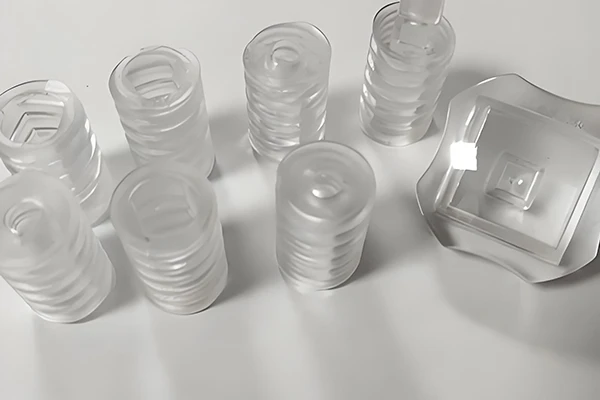

Precision plastic parts processing

Serve

Precision plastic parts refer to products with high precision, Plastic products with high complexity and strict quality requirements. They are commonly used in a variety of precision equipment and products, Plays a key role in product performance and quality.

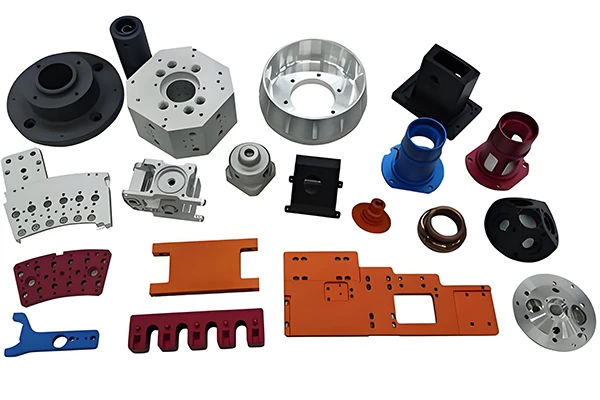

One-off CNC machining prototype

Our precision plastic processing capabilities

Choose Rapidefficient Precision Plastic Parts, The reasons are as follows: First, high precision, Can meet the requirements of strict parts matching accuracy scenarios, Ensure product performance and reliability; Second, excellent performance, Has good mechanical properties, such as intensity, Stiffness and toughness, Can withstand corresponding external forces and loads, There are also better impact resistance, etc.; The third is efficient production, Adopting advanced technology and processes, Ability to quickly produce high-quality parts, Shorten product development cycle and delivery time, Meet market demand for rapid response; Fourth, complex shapes can be realized, Parts with various complex geometric shapes can be manufactured, Meet product functional and design needs.

Precision plastic parts refer to products with high precision, Plastic products with high complexity and strict quality requirements. They are commonly used in a variety of precision equipment and products, Plays a key role in product performance and quality.

in industrial production, Precision plastic parts are widely used in automobile manufacturing, Medical equipment, consumer electronics, Aerospace, Industrial automation and other fields. For example, Plastic parts in car engines, Precision components in medical equipment, Housings and internal structural parts in consumer electronics products, etc., All require the use of precision plastic parts.

Injection molding: After heating and melting the plastic particles, Molten plastic is injected into the mold cavity through an injection molding machine, After cooling and solidification, the required parts are obtained. Injection molding is one of the most commonly used methods in precision plastic parts processing.

Extrusion molding: After heating and melting the plastic particles, Molten plastic is extruded into continuous profiles through an extruder, such as pipes, Rod, Plates, etc., Extrusion molding is suitable for producing parts with simple cross-section shapes.

Electronic equipment plastic parts

Such as mobile phone, Precision plastic casings for computers, etc., Buttons etc., High precision required、good appearance.

Automobile plastic parts

Automotive interior parts, Plastic parts around the engine, etc., Requires high temperature resistance, Wear resistance and other properties.

Medical device plastic parts

Such as testing instrument shell, Medical plastic products, High requirements for safety and sterility.

Optical instrument plastic accessories

like camera lens housing, Housings for optical instruments, etc., Extremely high requirements for dimensional accuracy and surface finish.

Precision gears and other transmission plastic parts

Manufacturing plastic gears, Racks and other transmission components, Meet specific transmission accuracy and reliability requirements.

Small precision structural plastic parts

Such as various buckles, Connectors, etc., Although small, it has strict requirements on size and mechanical properties.

Precision plastic parts display, High precision, Smooth surface, Complex and diverse structures, Reflect advanced manufacturing technology, Meet the needs of various fields.

High dimensional accuracy, Can meet precision equipment assembly needs, Ensure product performance is stable and reliable.

Material and processing costs are relatively low, Suitable for mass production, Reduce overall product cost.

Compared to metal parts, Plastic parts are lightweight, Easy to transport and install, Reduce energy consumption.

Design stage

1. Clarify needs: Determine the function of the part, Dimensional accuracy, Mechanical properties and other requirements, and usage environment and working conditions.

2. Select material: Choose the appropriate plastic material according to your needs, Consider the strength of the material, hardness, toughness, Temperature resistance, Corrosion resistance and other properties.

3. Optimize design: Design parts with advanced 3D design software, Optimize structure, Reduce wall thickness differences, Avoid sharp and sharp corners, To improve the molding quality and accuracy of parts.

Mold making

1. Choose mold manufacturer: Looking for a professional mold manufacturer, Inspect its equipment, technology, Experience and credibility.

2. Mold design: Cooperate with mold manufacturers, Carry out mold design, Ensure the mold structure is reasonable, Easy to process and maintain, At the same time meet the accuracy requirements of the parts.

3. Mold processing: Adopt high-precision processing equipment and technology, Such as CNC machining, EDM, Wire cutting, etc., Ensure the dimensional accuracy and surface quality of the mold.

Injection molding

1. Choose injection molding machine: Based on part size and output requirements, Choose the right injection molding machine, Ensure the stable performance of the injection molding machine, High control accuracy.

2. Debugging process parameters: Passed mold trial, Adjust injection molding temperature, pressure, speed, Process parameters such as time, To obtain the best molding effect.

3. Quality control: During the injection molding process, Perform real-time quality monitoring, Such as size measurement, Appearance inspection, etc., Find and solve problems promptly.

Post-processing

1. Remove gates and flash: Mechanically or chemically remove gates and flash from parts, Improve the appearance quality of parts

2. surface treatment: Surface treatment as needed, as polished, Spray, Electroplating, etc., Improve part surface finish and corrosion resistance.

3. Assembly and packaging: Assemble and package parts, Ensure parts are not damaged during transportation and storage.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential

Dimensional deviation: There is a difference between the actual production part size and the design size

Reason: Mold wear, Injection molding process parameters are unstable, Changes in material shrinkage, etc.

Solution

Regularly inspect and maintain molds, Ensure mold dimensional accuracy.

Optimize injection molding process parameters, such as adjusting the temperature, pressure, speed etc., Ensure process stability.

According to the shrinkage rate of the material, Reasonably adjust mold size.

Surface defects: Scratches appear on the surface of the part、bubble、Problems such as sink marks

Reason: Rough mold surface, Injection molding temperature is too high or too low, Injection speed is too fast or too slow, etc.

Solution

Polish the mold, Improve mold surface finish.

Adjust injection molding temperature and speed, Avoid going too high or too low.

Optimize the exhaust system of the mold, Prevent bubbles from forming.

Insufficient strength: Parts are prone to breakage or deformation during use

Reason: Improper material selection, Injection molding process is unreasonable, Unreasonable parts design and structure, etc.

Solution

Choose the right material, Ensure the strength and toughness of the material meet requirements.

Optimize the injection molding process, If the injection pressure is increased, Extend the holding time, etc.

Structural optimization of parts, Add reinforcement and other structures, Improve part strength.

Color difference problem: Parts produced in the same batch have inconsistent colors

Reason: Different batches of raw materials, Injection molding temperature and time changes, Inaccurate amount of color masterbatch added, etc.

Solution

Ensure batches of raw materials are consistent, Strictly control the quality of raw materials.

Stable injection molding process parameters, Avoid the effects of temperature and time changes on color.

Accurately control the amount of color masterbatch added, Make sure the color is even.

Our CNC machining services have been praised by global customers from different fields, We supply CNC machining components to a variety of industries, Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.