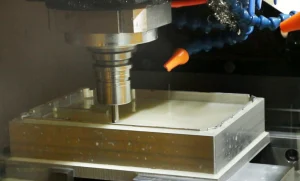

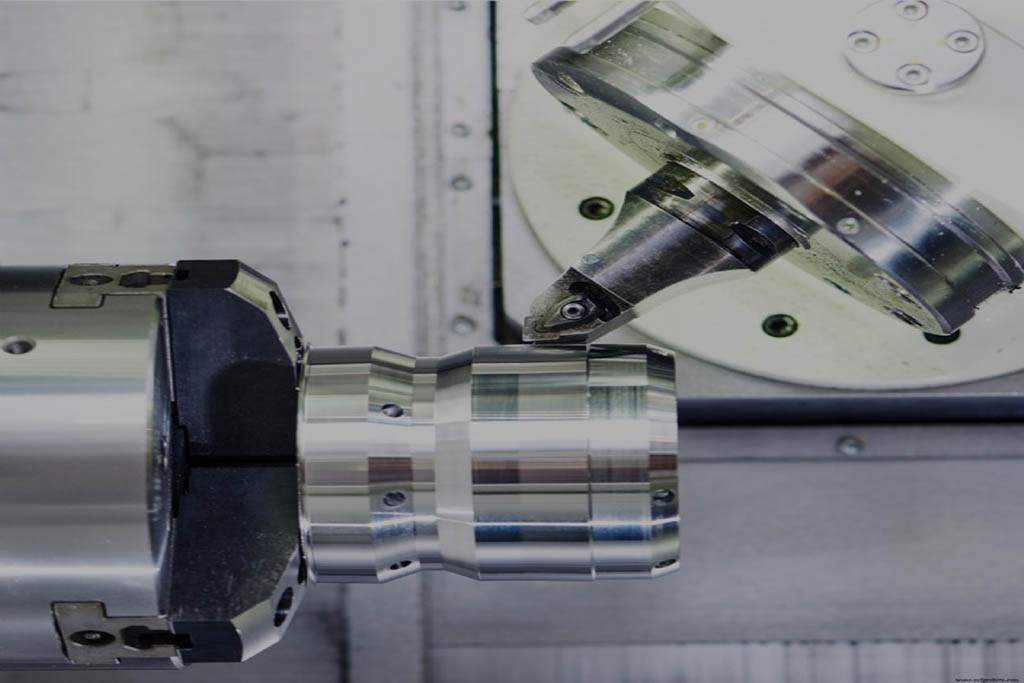

In the modern manufacturing landscape, CNC (Computer Numerical Control) machining plays a pivotal role in producing high-precision components. The quality control of CNC machining is essential for ensuring that the final products meet the required specifications and standards. This article will explore various aspects of quality control in CNC machining, highlighting its importance and best practices.

Quality control of CNC machining encompasses a range of processes and methodologies aimed at maintaining the integrity of the manufacturing process. The precision of CNC machines allows for intricate designs and complex geometries, but it also necessitates rigorous quality assurance measures. Implementing effective quality control strategies is crucial to minimize defects, reduce waste, and enhance overall productivity.

One of the primary aspects of quality control in CNC machining is the use of advanced measurement techniques. Tools such as coordinate measuring machines (CMM), laser scanners, and optical comparators are commonly employed to verify the dimensions and tolerances of machined parts. Regular inspections throughout the machining process help identify any deviations from the desired specifications, enabling timely corrective actions.

Another vital component of quality control of CNC machining is the establishment of clear standards and procedures. Standard Operating Procedures (SOPs) should be developed for every machining operation, detailing the necessary steps, acceptable tolerances, and inspection criteria. These SOPs serve as a reference for operators, ensuring consistency in production and adherence to quality benchmarks.

Training and skill development of CNC operators also play a significant role in quality control. Well-trained personnel are better equipped to identify potential issues during the machining process, which can prevent defects before they occur. Regular training sessions and workshops on the latest machining technologies and quality control methods can significantly enhance the overall quality of the output.

Furthermore, the use of statistical process control (SPC) techniques is becoming increasingly popular in quality control of CNC machining. By analyzing production data, manufacturers can identify trends and variations in the machining process. This proactive approach allows for adjustments to be made before problems escalate, thereby maintaining high standards of quality.

Collaboration between departments is also essential for effective quality control. Communication between engineering, production, and quality assurance teams ensures that everyone is aligned on quality objectives and standards. Regular meetings and feedback loops help in quickly addressing any quality-related concerns that may arise during the machining process.

Finally, continuous improvement is a cornerstone of quality control of CNC machining. Implementing methodologies such as Six Sigma or Lean Manufacturing can help organizations refine their processes, eliminate waste, and enhance quality. By fostering a culture of continuous improvement, companies can adapt to changes in market demands and technological advancements, ultimately leading to better quality outcomes.

It combines measurement, standards, training and continuous improvement. By prioritizing quality control, manufacturers can ensure that they produce high-quality components that meet customer expectations and industry standards. This commitment to quality not only enhances market competitiveness, but also builds a reputation for reliability and manufacturing excellence.