Vacuum casting

Serve

Vacuum casting is an advanced casting process, It injects liquid metal into the mold in a vacuum environment, to reduce pores, Defects such as inclusions, Improve casting quality and performance.

One-off CNC machining prototype

Our Vacuum Cast Parts Processing Capabilities

Choose Rapidefficient Vacuum Casting, Because it can reduce pore defects, Improve the density and mechanical properties of castings; Improve filling ability, Complex structural parts can be formed; Improve production efficiency, Shorten delivery cycle, and can reduce costs, Suitable for small batches, High quality parts production.

Vacuum casting is an advanced casting process, It injects liquid metal into the mold in a vacuum environment, to reduce pores, Defects such as inclusions, Improve casting quality and performance. in vacuum environment, Gases and impurities in the molten metal are better able to escape, Make castings denser, Uniform. at the same time, Vacuum casting also enables high-precision manufacturing of complex-shaped castings, Provides greater freedom for product design in many fields.

Commonly used materials:

copper alloy:

characteristic: Has good electrical conductivity, Thermal conductivity and corrosion resistance. Copper alloys have higher strength and hardness, Good wear resistance.

Application scenarios: Commonly used in manufacturing electrical equipment, Mechanical parts, Plumbing equipment, etc., Such as motor rotor, valve, faucets etc.

Magnesium alloy:

characteristic: Is one of the lightest metal structural materials, Has high specific strength and specific stiffness, Features such as good electromagnetic shielding performance. Magnesium alloy has excellent shock absorption properties, Suitable for areas with high weight and performance requirements.

Application scenarios: Mainly used in aerospace, automobile manufacturing, Electronic communications and other fields. such as airplane seat frame, car dashboard bracket, Mobile phone casing, etc.

Auto parts manufacturing

Capable of producing complex automotive parts with high precision, such as engine block, Transmission housing, etc., Meeting the high demands of the automotive industry.

Aerospace components

Can produce fine structures, Reliable aerospace components, Adapt to high altitude, High speed and other extreme environments.

Medical device production

Used to manufacture precision medical devices, such as surgical instruments, Implants etc., Ensure product safety and accuracy.

Electronic product casing

Good at creating thin walls, High-precision electronic product casing, Provide good protection and appearance for electronic products.

Art sculpture creation

Able to achieve complex artistic sculpture shapes, Accurately replicate an artist’s design, Show unique artistic effects.

Small precision machinery parts

Can produce various small precision mechanical parts, like gears, Bearings, etc., Provide high-quality parts for the machinery industry.

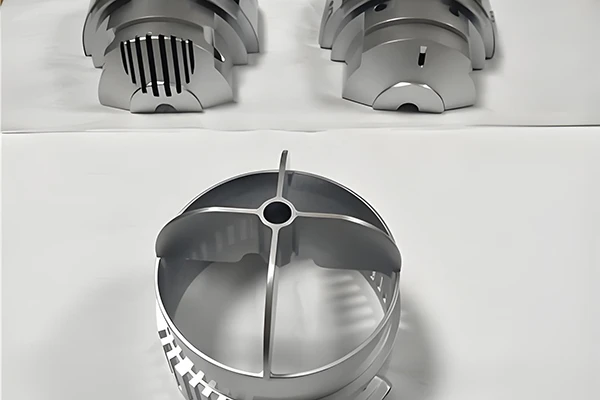

Stunning display of vacuum cast parts. High precision, Smooth surface, Complex structures perfectly presented, Highlight the charm of advanced manufacturing technology.

Reduce casting porosity, Increase density, Enhance the mechanical properties of parts, Ensure product quality is stable and reliable.

Improve the fluidity of molten metal, Can form complex structural parts, Meet diverse design needs.

High dimensional accuracy, Reduce subsequent processing, Reduce costs, Improve production efficiency.

Learn about the vacuum casting process

Vacuum casting is to inject molten metal into the mold cavity under negative pressure, The manufacturing process that solidifies it into shape. Be familiar with its principles, Applicable materials and main application fields.

Determine needs

Identify specific requirements for vacuum cast parts required, including size, shape, Accuracy, Performance etc., Consider its function in the product and the environment in which it is used.

Choose the right material

Common vacuum casting materials include aluminum alloy, Magnesium alloy, Copper alloy, etc., Select appropriate materials based on factors such as part performance requirements and cost.

Design and mold making

1. Vacuum casting process characteristics should be considered when designing parts, Avoid difficult-to-form structures. Reasonable design of wall thickness, Release angle, etc.

2. Entrust professional mold manufacturers to make high-quality molds, Ensure mold accuracy and durability.

Production process control

1. Strictly control vacuum degree, Pouring temperature, Pouring speed and other parameters, Ensure stable parts quality.

2. Perform appropriate post-processing, Such as deburring, Surface treatment, etc., Improve part appearance and performance.

Quality inspection

1. Comprehensive quality inspection of vacuum cast parts, Includes dimensional measurements, Appearance inspection, Mechanical property testing, etc.

2. Use advanced testing equipment and methods, Ensure parts meet quality standards.

Packaging and storage

Use appropriate packaging, Prevent parts from being damaged during shipping and storage. Storage environment should be dry, clean, Avoid parts getting wet, rust.

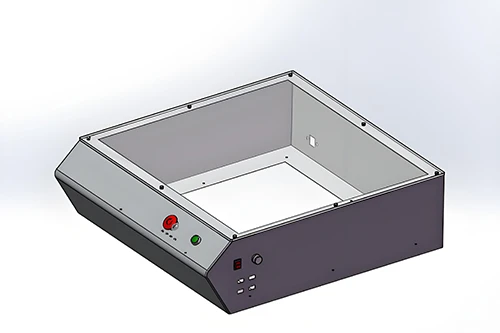

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential

Surface defects: Flow marks may appear, Cold insulation, Surface problems such as blisters

Reason: Improper design of the pouring system, The temperature of the molten metal is inappropriate, Rough mold surface, etc.

Solution

Optimize pouring system, Ensure smooth flow of molten metal.

Adjust molten metal temperature and pouring speed, keep it within the appropriate range.

Polish the mold, Improve mold surface quality.

Internal defects: like pores, shrinkage cavity, Inclusions, etc.

Reason: Insufficient vacuum, Incomplete degassing of molten metal, Pouring speed is too fast, etc.

Solution

Increase vacuum level, Ensure that the gas in the mold cavity is fully exhausted.

Fully degassing the molten metal, If vacuum degassing is used, Inert gas stirring and other methods.

Control pouring speed, Avoid turbulence in molten metal and gas entrainment.

Dimensional deviation: Actual size differs from design size

Reason: Mold deformation, Process parameters are unstable, Measurement error, etc.

Solution

Check the mold regularly, Prevent mold deformation.

Stable process parameters, Strengthen process control.

Use high-precision measuring equipment, Reduce measurement errors.

Poor mechanical properties: strength, Mechanical properties such as hardness do not meet requirements

Reason: Improper material selection, The heat treatment process is unreasonable, Effect of casting defects, etc.

Solution

Choose the right material, Ensure that the mechanical properties of the material meet the requirements.

Optimize heat treatment process, Improve the strength and hardness of parts.

Reduce casting defects, like pores, Shrinkage cavities, etc., Improve part density.

Our CNC machining services have been praised by global customers from different fields, We supply CNC machining components to a variety of industries, Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.