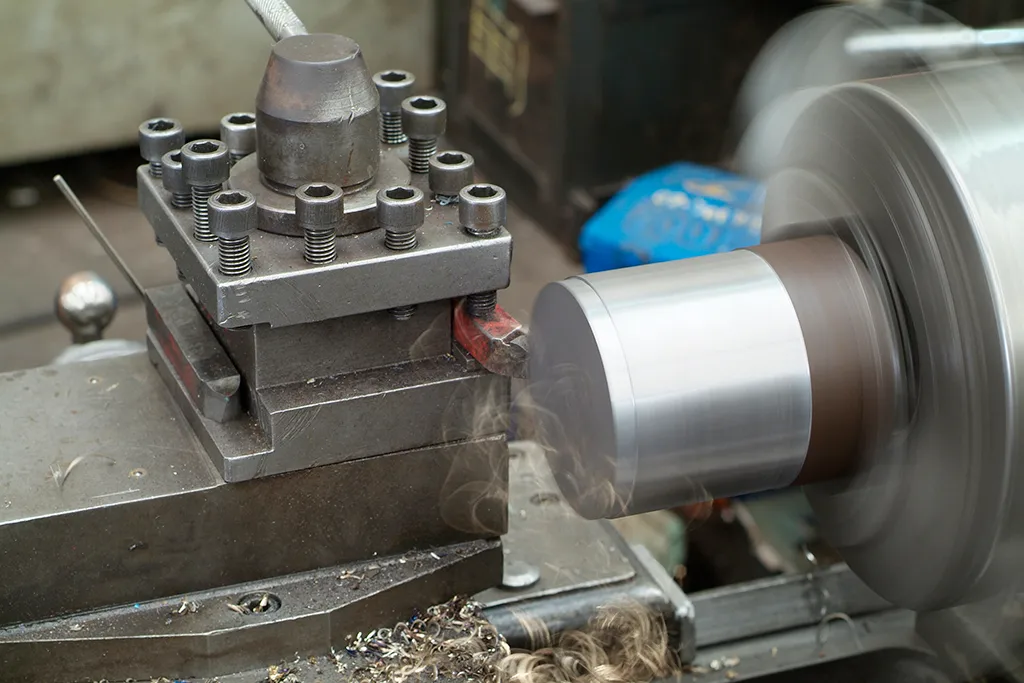

CNC turning is a crucial manufacturing process. It involves shaping materials into precise cylindrical parts using computer-controlled lathes. As industries evolve, various types of CNC turning emerge. Each type serves specific purposes and offers unique advantages. In this article, we will explore the different types of CNC turning and their applications.

1. Conventional CNC Turning

Conventional CNC turning is the most common type. It uses a standard lathe machine controlled by a computer. Operators input specifications into the system, which then guides the cutting tools. This method is suitable for producing simple cylindrical shapes. It works well for small to medium production runs.

Moreover, conventional CNC turning provides high precision. Manufacturers can create parts with tight tolerances. As a result, this type is widely used in industries like automotive and aerospace.

2. CNC Swiss Turning

CNC Swiss turning is another specialized method. It originated from Swiss watchmaking. This type utilizes a sliding headstock. The material is fed through a guide bushing, which stabilizes it during the process.

CNC Swiss turning is ideal for creating small, intricate parts. It excels in high-volume production. The setup reduces tool wear and increases precision. Industries such as medical devices and electronics frequently use this method.

3. CNC Vertical Turning

CNC vertical turning machines operate differently from traditional lathes. In this setup, the workpiece stands vertically. The cutting tools approach from above. This orientation allows for efficient chip removal.

CNC vertical turning is particularly useful for large, heavy parts. It enhances stability and accuracy during the cutting process. Manufacturers often use this type for producing components like rotors and large flanges.

4. CNC Horizontal Turning

CNC horizontal turning is the counterpart to vertical turning. In this case, the workpiece is positioned horizontally. The cutting tools move along the X and Z axes. This setup is versatile and allows for various operations.

Horizontal turning is effective for a wide range of applications. It is commonly used in automotive and manufacturing industries. Moreover, it supports additional processes like milling and drilling, increasing overall productivity.

5. CNC Multi-Axis Turning

CNC multi-axis turning machines offer advanced capabilities. These machines can rotate the workpiece around multiple axes. As a result, they can create complex geometries and intricate designs.

Multi-axis turning is ideal for high-precision components. It reduces the need for multiple setups, saving time and effort. Industries such as aerospace and defense benefit from this technology.

6. CNC Turning with Live Tools

CNC turning with live tools combines turning and milling operations. This type uses a lathe with rotating tools. These tools can perform additional machining tasks during the turning process.

This capability allows for more complex shapes in a single setup. It reduces production time and enhances efficiency. Industries that require intricate parts often prefer this method.

7. CNC Turning for Hard Materials

CNC turning for hard materials focuses on machining tough substances. This type uses specialized tools and techniques to handle materials like titanium and hardened steel.

These machines ensure precision and durability. They are essential in industries like aerospace and defense, where material strength is crucial.

Conclusion

In conclusion, CNC turning encompasses various types, each tailored for specific applications. From conventional to advanced multi-axis turning, each method offers distinct advantages. As technology continues to evolve, the capabilities of CNC turning will expand. Businesses must understand these types to choose the right method for their needs. Embracing the appropriate CNC turning type can lead to enhanced efficiency and superior product quality.