CNC machining Services

As our featured business, From prototyping to production parts, Match your plastic and metal parts with the most suitable CNC machining services and produce and deliver them on demand.

One-off CNC machining prototype services

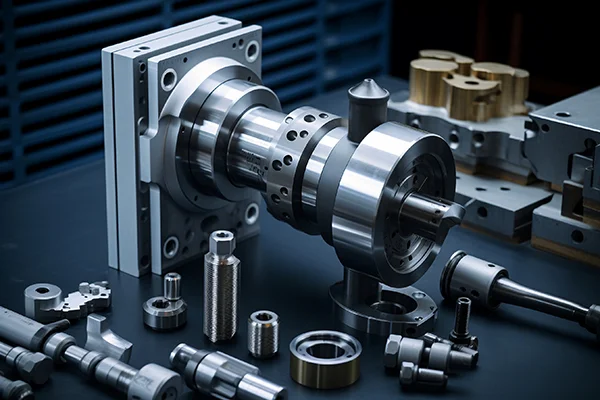

Our CNC machining services capabilities

If you are looking for a reliable custom metal fabrication parts Services manufacturer, RapidEfficiency will be your ideal solution. We are an excellent CNC machining manufacturer, Specializing in CNC prototype processing for design verification and small batch customized CNC parts processing, Whether it is a simple or complex geometric part, We are all confident in our CNC machining capabilities, We will solve the manufacturing issues within a few days and maintain good quality.

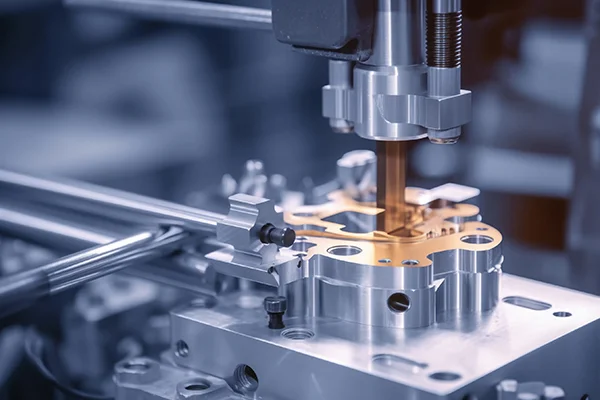

CNC numerical control machining, The full name is Computer Numerical Control CNC machining, It is a processing method that uses a digital control system to accurately control machine tools.

It works like a precise conductor, Through pre-programmed instructions, Precisely control the tool movement trajectory of the machine tool, Parameters such as cutting speed and feed. Compared with traditional processing methods, CNC machining has significant advantages. first, It enables extremely high machining accuracy, Tolerances can be strictly controlled within a very small range, Ensure product quality and consistency. Whether it’s complex geometries or fine details, CNC machining can be easily handled.

Secondly, CNC machining is efficient. Once the program is set, The machine tool can continuously, Process stably, Greatly improved production efficiency. at the same time, It can also realize automated processing, Reduces errors and labor intensity caused by manual operations.

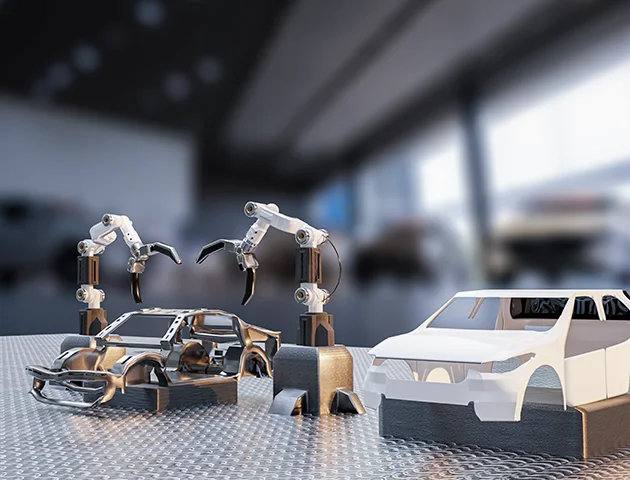

in various fields, CNC machining services has a wide range of applications. In aerospace field, High-precision parts are inseparable from CNC machining; Automobile manufacturing industry, Complex engine components also benefit from this advanced processing method. also, medical device, Electronic products and other fields are also highly dependent on CNC machining.

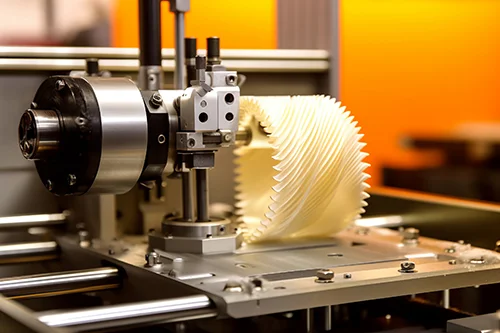

CNC prototyping of complex designs

We specialize in CNC precision machining of functional prototypes with complex geometries, Provide superior support for your design verification and engineering testing. For example, Detail-oriented optical parts, and aluminum housing parts with complex structures.

Customized low-volume CNC machining

Need to get your product to market faster? It turns out, CNC machining is a versatile solution for producing custom parts quickly and flexibly. Our experienced team can increase efficiency and reduce processing costs with flexible machine configurations and machining practices, Can provide customized small batch CNC machining services for any industry.

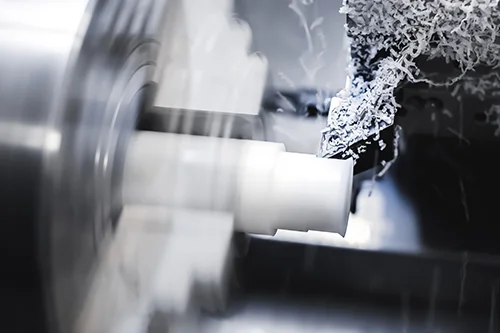

CNC turning

We provide fast, Precision CNC turning services include extensive customer guidance and support, From start to part completion.

CNC milling

With our high-precision three-axis, Four- and five-axis CNC machining centers, We have professional CNC milling capabilities and an experienced team, Can efficiently produce milled parts with very tight tolerances and high-quality surface finishes.

CNC machining

In the machining industry, Metal processing is considered the most widespread part processing technology, CNC metal processing can provide tighter processing accuracy. More stable processing quality and higher processing efficiency.

CNC plastic processing

Need some custom plastic prototypes or production-grade plastic parts? We offer CNC plastic machining, Manufacturing high quality machined plastic parts at competitive prices for global customers.

In order to let you intuitively feel our CNC machining Services strength, Here are some of our past project results, and demonstration components carefully designed by professional engineers. Our team has demonstrated exceptional flexibility with all types of CNC machined components. so, If you are looking for a CNC machining company for your project, Then you don’t have to run around anymore!

We adopt international standards ISO 2768 To control uninjected linear tolerances of machined parts, Among them ISO 2768(F) applies to metal parts, ISO 2768 (M) is suitable for plastic parts. Normally, We can guarantee processing accuracy of ± 0.10mm to ±0.05mm. If tighter tolerances are required, You will need to provide a 2D drawing with complete annotation information, Our engineering team will communicate critical dimensional tolerances with you, and provide the highest possible processing accuracy. What’s important, due to increased scrap rates, Additional fixtures and/or specialized measuring tools, Tighter tolerances may result in additional costs.

We have more than 30 A variety of engineering-grade plastic and metal materials, CNC part machining applications for a variety of industries. plastic: ABS, PC, ABS+PC, PMMA(Acrylic), PA(nylon), PA+glass fiber, POM, PP, PP+glass fiber, PVC, HDPE, PPS, PEEK, PEI(Ultimate), Teflon, Bakelite, Substitute tree.

Metal: aluminum, steel, Stainless steel, brass, red copper, bronze, Magnesium alloy, Titanium alloy, zinc alloy.

We support one-stop surface treatment, To meet the visual and functional requirements of any design. Including sanding, sandblasting, Mirror polished, spray paint, silk screen, Laser engraving, anodizing, plating, chrome plated, Powder spraying etc.

Avoid thin walls

Same as high features, Vibration increases when machining thin features. as a guide, The minimum thickness of metal thin-walled parts is 0.5-0.8mm, The minimum thickness of plastic parts is 1.0-1.5mm. If the wall is used for supporting or higher features, The wall thickness should be increased, To avoid vibration during processing.

Avoid small or raised text

You may need to mark the part with the part number or company name, Adding text looks cool, But processing is very time-consuming, Electrochemical etching or laser engraving is usually better. If you must mill text, Choose sunken rather than raised text whenever possible, Keep it simple with larger text, Font depth does not exceed 0.3mm.

Adhere to thread standards

When creating threads, It’s also important to stick to standard sizes. The larger the thread, The easier it is to process. The length should be kept to a maximum of the nominal diameter of the hole 3 times. For blind hole tapping, It is best to add at least at the root of the hole 1/2 Extra length of aperture. You may also consider using inserts, Threaded coils and copper nuts last longer than bare machined threads, Especially in materials like aluminum or plastic, and easy to install.

The largest possible interior angle

Any internal cuts will create fillets, It is half the diameter of the tool used. Milling with smaller tools takes a long time, We recommend that the radius should be larger than the machining depth 1/3. The best approach is to eliminate interior corners or allow the largest possible interior corner radius in the mating part design, and use the same radius on all inner edges, so that the same tool can be used throughout the process.

Avoid too deep cavities、Grooves and deep holes

The depth of the pocket and groove is usually related to the diameter of the tool used to machine the internal fillet. A good rule of thumb is to keep the pocket depth equal to the tool diameter 3-4 times, Or the groove depth is smaller than the feature width 4 times. Whether blind hole or through hole, Recommended maximum depth is diameter 4 times, The minimum aperture is 1 mm, And it is recommended to design standard size holes. Use a standard drill bit, Can process holes quickly and with high precision; For non-standard holes, Using end mills increases costs.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential

We provide new product developers with machined parts from engineering-grade materials suitable for functional testing or end-use applications. Get the CNC machining support you need by reading the FAQ.

What are the tolerances for manufacturing parts?

The tolerance range of sheet metal processing parts is ±0.2-0.3mm.

What are the quality standards for small batch production services?

We have strict quality control standards, To ensure the quality of small batch production. first, We inspect incoming materials to ensure material quality. Secondly, We inspect and test the production process, To ensure you get quality parts that exceed your expectations. third, We can provide certificates of conformity for all materials.

What is the cost of efficiently machined parts?

Our engineering and sales teams will provide one-on-one quoting support for your project. Normally, for similar parts, CNC lathe machining costs are 15% lower than 3-axis CNC milling. compared to this, 5The cost of shaft machining has increased, 5The processing cost of axis-linked CNC milling is usually more than 20% higher than that of 3+2 machine tools, About twice as long as a standard 3-axis mill. For the most cost-effective CNC machined parts, Recommended for larger production runs, To spread the cost of machine setup.

What information do you need to provide a quote?

To provide meaningful offers, We need the following information:

We accept 2D and 3D CAD data in any format, Includes STP, IGES, X_T, DWG, PDF, STL;

expected quantity, Processing technology, and the required raw materials;

Any necessary secondary operations, Includes finishing specifications, heat treatment, Oxidation or electroplating, etc.;

Any applicable customer specifications, For example, first article inspection, PPAP requirements and required external process certificates;

any other useful information, Such as target price or desired delivery time.

I don't have CAD data,Can you help me design the parts?

Designing parts is not within our scope as a contract manufacturer, But we can provide some guidance on Design for Manufacturability (DFM). via DFM, We can advise on how to optimize your design, Reduce costs while retaining functionality.

How soon can I receive your quote?

in most cases, We will respond to your quote within 1 working day. The best way to ensure a quick quote is to provide as many accurate details as possible.

What is the maximum size range of your machine tool travel?

Maximum stroke (3-axis machine tool): 1270×508×635 (mm).

Maximum stroke (5-axis machine tool): 450×700×400 (mm), Worktable rotation Φ400mm.

What machining tolerances can you achieve?

For CNC machining, Tolerances on all part dimensions will follow the ISO 2768-1 standard. if needed, You can specify tighter tolerances in part specs, This will require 2D technical drawings. Normally, We can control the tolerance range from ±0.125mm to ±0.05mm.

Tighter tolerances exceeding ±0.05mm will be reviewed by our engineers. please understand, Tolerances are greatly affected by part geometry and material type, Our project managers will consult with you on every part, And provide the highest processing accuracy within the allowable range as much as possible.

Importantly tighter tolerances may result in increased scrap rates, Additional costs due to additional fixtures and special measurement processes. The best way to apply tolerances is to apply tight tolerances only in critical areas, This will help keep costs to a minimum.

What kind of surface finish is left on CNC machined parts?

Once the processing is complete, CNC parts will have slight visible tool marks on the surface, call it”machined surface”. Machined surface roughness (Ra) The standard is 1.6-3.2μm, Surface finish requirements can be increased to 0.8-1.6μm, Or higher 0.2-0.8μm, However, this will require more operating time and higher costs.

Can Efficient provide optical quality transparent parts processing?

Yes. Efficient with 3 axes, 4Axis or even 5-axis CNC machining capabilities. We also use the latest diamond processing technology for ultra-precision processing. This is a type of processing known as single-point diamond processing(SPDM or SPDT)technology, It can match the capabilities of 5-axis micro milling, Produce a range of lens and light guide types with excellent optical quality in array or freeform mode. With rich polishing experience, We can achieve stunning looks inside and outside the part, Provide full support for transparent optical prototype development projects.

How does Efficiency ensure the quality of my parts?

If you are worried about the quality assurance of your order, ISO-9001 certified factory won’t let you down. We have dedicated testing equipment and skilled QC/QA personnel, 2D report/CMM report/3D scanning report can be provided, Ensure your part quality is within expectations.

All dimensional tolerances, 100% of geometric tolerances and special comments will be recorded according to our statistical sampling plan based on MIL-STD-105E, zero defect rate. All inspection reports will be shipped with your parts.

Rejected or nonconforming parts will be recorded and communicated based on the type of inspection agreed with the customer. Normally, For inspection items without 2D drawing size report, Efficient may rework parts found to be minor nonconforming (unable to be reworked to conform to requirements, And it is assumed that it does not affect the fit of the parts, form or function) sent to customer for review. For any order with formal inspection with dimensional report, Efficient will obtain customer opinions on the handling of all non-conforming issues that cannot be reworked before shipment.

What is your delivery time?

In fact, There is no standard delivery time, We will arrange the production plan based on the current workload. Once your purchase order is received, Documentation completed, Materials ready, We will promptly feedback the accurate delivery time, Usually delivered within 3 working days to a few weeks, This depends on the complexity of the part and the quantity of parts ordered.

Our CNC machining services have been praised by global customers from different fields. We supply CNC machining components to a variety of industries, Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.