Five-axis CNC machining

Five-axis CNC machining is an advanced manufacturing technology, It allows the machine tool to perform cutting operations simultaneously on five coordinate axes.

Start a new quote

Our five-axis CNC machining capabilities

There are many reasons to choose Rapidefficient 5-axis CNC machining. first, It can achieve high-precision machining, For complex parts, Multi-axis linkage can cut from different angles, Ensure dimensional accuracy and surface quality, Reduce errors. Secondly, Its processing efficiency is extremely high, Complete multi-faceted processing in one clamping, Reduce clamping times and time, High-speed cutting and rapid positioning further shorten the processing cycle. Furthermore, It is highly flexible, Accommodates a variety of materials and part types, Easy to program and operate, Can quickly respond to market changes. Whether it is aerospace or automobile manufacturing and other fields, It’s ideal.

CNC 5 Axis CNC machining is an advanced machining technology, It utilizes a computer numerical control (CNC) system to operate machine tools, Achieve high precision on workpieces, High efficiency processing.

In traditional three-axis CNC machining, The three axes of the machine tool are X, Y, Z axis, For controlling tool movement in three linear directions. and 5 Axis CNC machining adds two rotating axes on this basis, usually A, B, Two in the C axis. These two rotational axes allow the tool to approach the workpiece at different angles and directions, thereby enabling more complex machining operations.

one, High precision machining

5 Axis CNC machining enables high-precision machining of complex parts. Because there are two more rotation axes, The tool can approach the workpiece from different angles, Avoid machining errors caused by tool angle restrictions. at the same time, 5 Axis machining enables better control of tool cutting paths, Reduce the impact of cutting forces on the workpiece, thereby improving processing accuracy.

two, High efficiency production

5 Axis CNC machining can improve production efficiency. on the one hand, 5 Shaft machining can complete the processing of multiple surfaces in one clamping, Reduces the number of workpiece clamping times and adjustment time, Improved effective processing time of equipment. on the other hand, 5 Shaft machining can use more optimized cutting parameters, Increase cutting speed and feed, thereby shortening processing time.

three, Complex shape processing capabilities

5 Axis CNC machining can process parts of various complex shapes, such as freeform surface, impeller, Propellers, etc., By adjusting the angle of the rotation axis,Tools can cut in different directions, Achieve multi-sided processing and multi-angle processing. This flexibility allows 5 Axis CNC machining can adapt to the diverse needs of different industries.

Complex aviation parts processing

Precisely machine aircraft engine blades,Impellers and other components with complex curved surfaces and high precision requirements. Through multi-axis linkage, Able to process complex blade shapes in one go, Ensure the aerodynamic performance and strength requirements of the blades. at the same time, High-precision machining capabilities ensure dimensional tolerances and surface quality of parts, Meets the aviation industry’s stringent standards for safety and reliability.

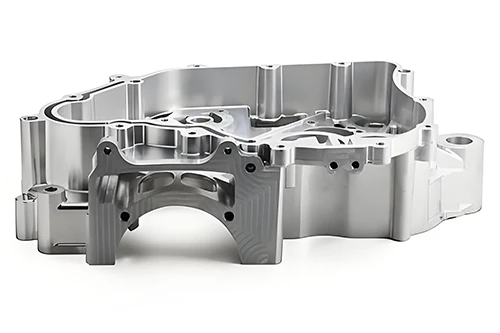

Automotive mold manufacturing

Efficient processing of automotive panel molds, Large and complex molds such as injection molds. 5 Axis CNC machining can complete the processing of multiple surfaces in one clamping, Reduces mold splicing errors, Improved mold accuracy and surface quality. at the same time, Fast processing speed can shorten the mold manufacturing cycle, Meet the automotive industry’s need for rapid launch of new products.

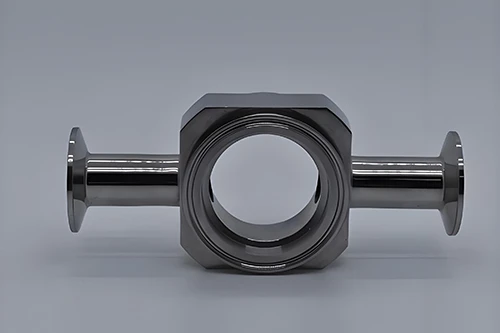

Medical device parts

Processing high-precision medical device parts, such as artificial joints, Dental implants etc., 5 Axis CNC machining enables machining of complex shapes, Ensure the dimensional accuracy and surface quality of parts, Meet biocompatibility and reliability requirements for medical devices. at the same time, A clean machining environment prevents contamination of parts, Ensure the safety of medical devices.

Electronic equipment housing processing

For mobile phone, Manufacturing precision casings for tablets and other electronic devices. 5 Axis CNC machining can produce complex surfaces and details, Give the shell a beautiful appearance and comfortable feel. at the same time, High-precision machining capabilities can ensure the matching accuracy of the outer shell and internal components, Improve the performance and reliability of electronic equipment.

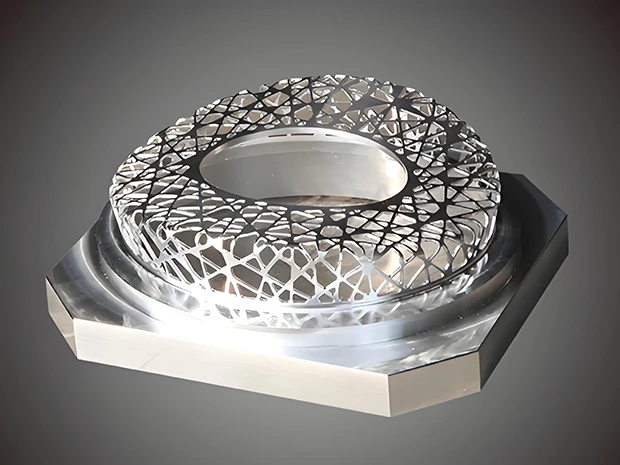

Handicraft processing

Create beautiful crafts, like sculpture, Jewelry, etc., 5 Axis CNC machining enables complex engraving and shaping, Create unique artistic effects. at the same time, High-precision processing capabilities can ensure the details and quality of handicrafts, Satisfy art lovers’ pursuit of beauty.

New energy equipment parts processing

Processing wind turbine blades, New energy equipment parts such as solar panel frames. 5 Axis CNC machining can accommodate the large sizes and complex shapes of these parts, Guarantee processing accuracy and surface quality. at the same time, Efficient processing capabilities can meet the needs of the new energy industry for mass production.

In order to let you intuitively feel our CNC machining strength, Here are some of our past project results, and demonstration components carefully designed by professional engineers. Our team has demonstrated exceptional flexibility with all types of CNC machined components. so, If you are looking for a CNC machining company for your project, Then you don’t have to run around anymore!

1. Multi-axis linkage realizes complex shape cutting: 5 Axis CNC machining via three linear axes (X, Y, Z) and the coordinated motion of the two rotation axes, Allows the tool to approach the workpiece from different angles and directions, Easily process various complex surface shapes. Whether it is turbine blades in the aerospace field, Molds for the automotive industry, Or precision parts in medical equipment. Can achieve high-precision processing.

2. Reduce machining errors: Compared with traditional three-axis machining, 5 Axis machining enables better control of tool cutting paths, Avoid machining errors caused by tool angle restrictions. at the same time, Multiple surfaces can be processed in one clamping operation, Reduces accumulated errors caused by multiple clamping, Greatly improved processing accuracy.

1. Improve production efficiency: 5 Axis CNC machining can complete multiple processes in one clamping, Reduces the number of workpiece loading and unloading times and adjustment time, Improved effective processing time of equipment. at the same time, Multi-axis linkage and high-speed cutting functions can speed up cutting speed, Shorten processing cycle, thereby significantly improving production efficiency.

2. Adapt to a variety of processing needs: 5 Axis CNC machining offers high flexibility, Ability to adapt to different materials, Processing of workpieces of different shapes and sizes. Whether it is small precision parts or large complex structural parts, Tool paths and machining parameters can be adjusted programmatically, achieve efficiency, Precise processing. also, Customized processing can also be carried out according to customers’ special requirements, Meet diverse market needs.

1. Advanced CNC system: 5 Axis CNC machining adopts advanced CNC system, With powerful computing power and precise control functions. Enables complex programming and tool path planning, Automatically optimize processing parameters, Improve processing quality and efficiency. at the same time, The CNC system also has fault diagnosis and self-repair functions, Ensure the stable operation of the equipment.

2. Automated production: 5 Axis CNC machining can be integrated with automated production lines, Realize unmanned production. Through automated loading and unloading system, Cooperation with equipment such as robot handling, Continuous processing can be achieved, Greatly reduced labor costs, Improved safety and reliability of production. also, Remote monitoring and management can also be achieved through network connection, Further improve the level of intelligence in production.

Preparation before processing

1. Design and programming

According to the shape of the workpiece, Dimensions and processing requirements, Design and program using professional CAD/CAM software. Make sure tool paths are reasonable, Cutting parameter optimization, to improve processing efficiency and quality.

For complex parts, Multiple simulation processing may be required, To verify the correctness and feasibility of the program.

2. Tool selection

According to workpiece material, Processing technology and accuracy requirements, Choose the right tool. 5 Axis CNC machining often requires the use of high-performance tools, Such as carbide cutting tools, Coated tools, etc.

Consider the diameter of the tool, length, Number of blades and other parameters, And the way the tool is clamped, Ensure that the tool can cut stably.

3. Workpiece clamping

Choose the right fixture, Ensure the workpiece is stable and reliable during processing. For workpieces with complex shapes, Special clamps or combination clamps can be used.

Pay attention to the positioning accuracy of the workpiece, Avoid processing errors caused by improper clamping.

Process

1. Machine tool operation

Familiar with machine tool operation panels and control systems, Start the machine tool according to the operating procedures, stop, Feeding and other operations.

during processing, Pay close attention to the operating status of machine tools, Such as cutting force, temperature, Vibration etc., Adjust cutting parameters in time or take corresponding measures.

2. Toolpath control

Monitor the cutting path of the tool, Ensure that the tool cuts according to the programmed trajectory. If it is found that the tool deviates from the trajectory or an abnormality occurs, Processing should be stopped immediately, Check programs and tools.

Utilize the automatic compensation function of machine tools, Such as tool radius compensation, Length compensation, etc., Improve machining accuracy.

3. Cutting parameter adjustment

According to workpiece material, Tool performance and processing requirements, Reasonably adjust cutting speed, Feed amount, Cutting depth and other parameters. On the premise of ensuring processing quality, Maximize cutting efficiency.

Pay attention to the impact of changes in cutting parameters on machining accuracy and surface quality, Make timely adjustments.

Post-processing

1. Workpiece inspection

After processing is completed, Use measuring tools to inspect workpieces, Such as calipers, micrometer, Three coordinate measuring instrument, etc., Ensure the dimensional accuracy of the workpiece, Shape accuracy and surface quality meet requirements.

If processing errors are found, The cause should be analyzed and corresponding measures should be taken to correct it.

2. Tool maintenance

Check tool wear, Replace severely worn tools promptly. For tools that can be resharpened, Timely sharpening and maintenance should be carried out.

Clean chips and oil from tools and fixtures, Keep tools and jigs clean.

3. Machine tool maintenance

After processing is completed, Clean and maintain machine tools, Such as wiping the surface of the machine tool, Clean the chip bin, Add lubricating oil, etc.

Regularly perform accuracy testing and adjustments on machine tools, Ensure stable performance of machine tools.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential.

1. Programming is complex

1. Multi-axis linkage programming is difficult: 5 Axis CNC machining involves the coordinated movement of multiple axes,Tool paths need to be considered when programming, Rotation axis angle, Feed speed and other factors, Programming is difficult.

2. High demands on programmers: Requires programmers to have deep mathematics, Machining and programming knowledge, Familiar with the operation of CAM software and 5 Process characteristics of shaft machining.

2. Tool selection and management

1. Multi-axis linkage programming is difficult: 5 Axis CNC machining involves the coordinated movement of multiple axes, Tool paths need to be considered when programming, Rotation axis angle, Feed speed and other factors, Programming is difficult.

2. High demands on programmers: Requires programmers to have deep mathematics, Machining and programming knowledge, Familiar with the operation of CAM software and 5 Process characteristics of shaft machining.

3. Machine tool accuracy and stability

1. Multi-axis linkage programming is difficult: 5 Axis CNC machining involves the coordinated movement of multiple axes, Tool paths need to be considered when programming, Rotation axis angle, Feed speed and other factors, Programming is difficult.

2. High demands on programmers: Requires programmers to have deep mathematics, Machining and programming knowledge, Familiar with the operation of CAM software and 5 Process characteristics of shaft machining.

4. Processing technology and parameter selection

1. Multi-axis linkage programming is difficult: 5 Axis CNC machining involves the coordinated movement of multiple axes, Tool paths need to be considered when programming, Rotation axis angle, Feed speed and other factors, Programming is difficult.

2. High demands on programmers: Requires programmers to have deep mathematics, Machining and programming knowledge, Familiar with the operation of CAM software and 5 Process characteristics of shaft machining.

5. Higher cost

1. Multi-axis linkage programming is difficult: 5 Axis CNC machining involves the coordinated movement of multiple axes, Tool paths need to be considered when programming, Rotation axis angle, Feed speed and other factors, Programming is difficult.

2. High demands on programmers: Requires programmers to have deep mathematics, Machining and programming knowledge, Familiar with the operation of CAM software and 5 Process characteristics of shaft machining.

Our CNC machining services have been praised by global customers from different fields.We supply CNC machining components to a variety of industries, Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.