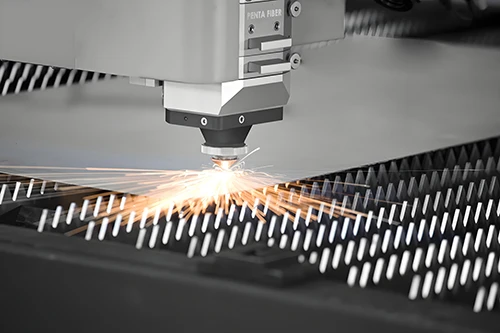

Laser cutting

Serve

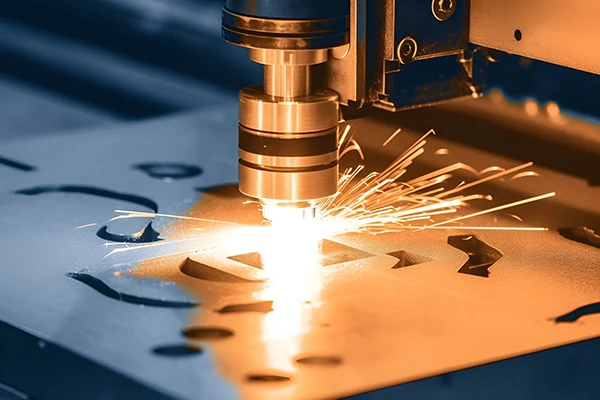

Laser cutting uses high power density laser beam as heat source, through computer-aided design and manufacturing technology, Precisely control the path and energy of the laser beam, Achieve efficient cutting of various materials.

One-off CNC machining prototype

High precision

High speed

Adaptable

Our laser cutting capabilities

Choose Rapidefficient Laser Cutting, because it has excellent advantages. Its high-precision cutting ensures precise product dimensions, Smooth edges, Can meet various stringent quality requirements. The high-speed cutting process greatly improves production efficiency, Shorten delivery cycle. at the same time, It is adaptable, Can cut a variety of materials and complex shapes, Meet the needs of different industries. Professional team, Advanced equipment and strict quality control, Let your products achieve perfect transformation in laser cutting, Choosing it means choosing efficiency and quality.

Laser cutting uses high energy density laser beam to irradiate the workpiece, Rapidly melt the irradiated material, Vaporization, Burn or reach ignition point, At the same time, the molten material is blown away with the help of high-speed airflow coaxial with the beam, To achieve a processing technology that cuts materials. Laser cutting uses high energy density laser beam to irradiate the workpiece, Rapidly melt the irradiated material, Vaporization, Burn or reach ignition point, At the same time, the molten material is blown away with the help of high-speed airflow coaxial with the beam, To achieve a processing technology that cuts materials.

High precision

Laser beams can be focused to very small spot diameters, Usually between a few microns and tens of microns, This enables laser cutting to achieve extremely high precision. Whether cutting straight lines, Curves or complex geometric shapes, Can ensure dimensional accuracy and edge smoothness. For example, In the field of electronic manufacturing, Laser cutting can precisely machine tiny circuit board parts.

high speed

Laser cutting is very fast, Can greatly improve production efficiency. Compared with traditional cutting methods, Laser cutting does not require physical contact of the tool, Therefore, a large number of cutting tasks can be completed in a short time. For example, in the automobile manufacturing industry, Laser cutting can quickly cut body panels into various shapes, Meet the needs of mass production.

High flexibility

Laser cutting can accommodate a variety of different materials and thicknesses, including metal、nonmetal, Thin plates, Japanese thick plates, etc., at the same time, Laser cutting can also achieve cutting of complex shapes, like a curve, Arc, Special-shaped holes, etc., Meet the personalized needs of different customers. For example, In the advertising signage production industry, Laser cutting can be done according to customer’s design requirements, Cut a variety of materials into unique shapes and patterns.

Small heat affected zone

Since laser cutting is a non-contact processing method, The energy of the laser beam is mainly concentrated in a small area, Therefore, the heat affected zone of the material is very small. This prevents the material from deforming during the cutting process, Problems such as discoloration or residual stress, Guaranteed material quality after cutting. For example, In the field of precision machinery manufacturing, Laser cutting can process high-precision parts, without affecting its performance and accuracy.

Sheet metal processing

High precision cutting:

Can treat all kinds of metal plates, such as stainless steel, carbon steel, Aluminum alloy, etc., Make precise cuts, High cutting dimensional accuracy, Can satisfy such as aerospace, Precision instrument manufacturing and other industries that have strict requirements on precision of parts. For example, sheet metal cutting for aircraft shells, Ensure high precision of splicing of each component.

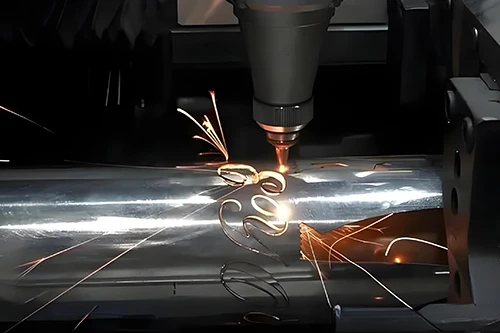

Pipe cutting

Cutting of various pipe shapes:

Whether it is round, Square or special-shaped pipes, Can perform accurate cutting, meet architecture, furniture, The processing needs of different shapes of pipes in sports equipment and other industries. For example, in the manufacturing of construction scaffolding, Cutting of steel pipes of various shapes.

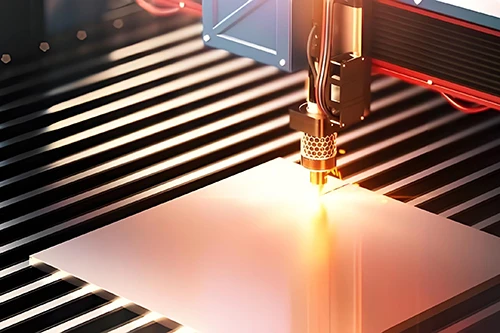

Thin plate cutting

Very thin sheet cutting:

For thickness in 0.1 – 1 mm extremely thin metal or non-metallic sheets, Such as copper foil in electronic circuits, Stainless steel sheets, etc., Able to achieve no deformation, Burr-free cutting, Guarantee product quality and performance.

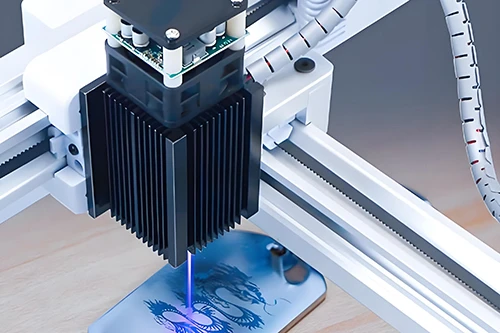

Complex patterns and engravings

Fine pattern cutting and engraving:

In the advertising signage industry, Able to cut various fine, complex text, graphics and patterns, Such as large billboards in shopping malls, Shop signs, etc., Smooth cutting edge, Beautiful effect.

Non-metallic material processing

Organic glass (acrylic) processing:

Can cut acrylic sheets, engraving, Various processing operations such as drilling, Produce various display stands, light box, Decorations etc., For example, in the production of shopping mall display cabinets, Cut acrylic sheets of different shapes and sizes for splicing and assembly.

Customized projects

Special shape and size customization:

Able to meet special shape and size requirements provided by customers, Carry out customized cutting processing, Whether it is a large building component or a small precision part, can meet the individual needs of customers.

In the laser cutting parts display area, Amazing variety of exquisite parts. Metal decorative parts with complex geometric shapes, Smooth lines, Extremely high precision. Precision electronic component framework, Accurate dimensions, Provide reliable support for electronic products. There are also unique handicrafts, Demonstrating the powerful creativity of laser cutting. These parts fully demonstrate the high precision of laser cutting, High speed and flexibility, Bringing more possibilities to product design and manufacturing in various industries.

Laser cutting enables extremely high precision, Smooth and neat cutting edges, Minimal dimensional error. Whether it is delicate electronic components or complex mechanical parts, can be cut accurately according to design requirements. For example, in medical device manufacturing, Laser cutting can ensure that the dimensional accuracy of parts reaches the micron level, Guarantee the accuracy and reliability of medical equipment.

Laser cutting is fast, Greatly improved production efficiency. Compared with traditional cutting methods, Laser cutting can complete a large number of cutting tasks in a short time. For example, in the automobile manufacturing industry, Laser cutting can quickly cut body panels into various shapes, Meet the needs of mass production.

Laser cutting can accommodate a variety of different materials and shapes, Whether it’s metal, Non-metals or complex curves and special-shaped structures, Can handle it easily. For example, In the advertising signage production industry, Laser cutting can be done according to customer’s design requirements, Cut a variety of materials into unique shapes and patterns, Meet individual needs.

Design stage

1. Clarify needs: Determine the material to be cut, shape, Dimensional accuracy requirements and cutting quantity, etc.

2. Drawings: Draw detailed 2D or 3D graphics using professional design software, Mark the dimensions and cutting paths clearly.

Material preparation

1. Choose the right material: Select materials suitable for laser cutting according to design requirements, Such as metal (stainless steel, carbon steel, Aluminum alloy, etc.), Non-metallic (acrylic, wood, plastic, etc.).

2. Check material quality: Make sure there are no obvious scratches on the surface of the material, Defects such as rust, Material thickness is uniform.

Equipment debugging

1. Install laser cutting head: Choose the appropriate laser cutting head based on material thickness and cutting requirements, and correctly installed on the laser cutting machine.

2. Adjust parameters: Set laser power, cutting speed, Gas pressure and other parameters. Generally speaking, Thicker materials require higher power and slower cutting speeds.

3. focus: Focus the laser beam onto the material surface, Ensure optimal cutting results. This can be achieved by adjusting the height of the cutting head or using the autofocus function.

Cutting operation

1. fixing material: Secure the material securely to the laser cutting machine’s table, Prevent movement during cutting.

2. Start cutting: After confirming that everything is ready, Start the laser cutting machine, Cut according to the preset cutting path.

3. Monitor the cutting process: during the cutting process, Watch the cutting closely, Such as cutting edge quality, Is there any abnormal situation, etc., If you have any questions, Adjust parameters in time or pause cutting for processing.

Post-processing

1. Remove burrs: There may be some burrs on the edge of the part after laser cutting, Sandpaper can be used, File and other tools for removal.

2. Clean parts: Use detergent or compressed air to remove dust from the surface of the parts, Remove oil stains and other impurities.

3. Quality inspection: Dimensional measurements of cut parts, Appearance inspection and other quality inspections, Ensure compliance with design requirements.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential.

Solution to Unsmooth Cutting Edge

Check whether the laser power is stable, If there is any problem, adjust or repair the laser in time.

Optimize cutting speed, Choose the appropriate speed based on material type and thickness.

Adjust focus position, Make sure the laser focus is on or slightly below the surface of the material.

Adjust auxiliary gas pressure, Choose the right gas type and flow rate.

Clean the material surface, Remove oil and rust.

Solutions to cutting size deviations

Double check programming data, Make sure it’s accurate.

Regularly calibrate equipment for accuracy, Ensure equipment accuracy.

Preprocess the material, Reduce deformation.

Consider the heat affected zone, Dimensional compensation during programming.

Solutions to sparks or splashes during cutting

Reduce laser power, Avoid excessive melting of materials due to excessive power.

Increase cutting speed, Reduce heat accumulation.

Adjust auxiliary gas pressure, avoid excessive stress.

Clean the material surface, Remove impurities.

Solution to incomplete cutting or over-burning

Increase laser power, Ensure sufficient energy to cut materials.

Reduce cutting speed, Give the material enough time to be cut.

Adjust focus position, Make sure the focus is in the right place.

Check whether the material thickness is even, If there is any problem, replace the material.

Equipment failure solutions

Perform regular maintenance on equipment, Extend equipment life.

Strengthen operator training, Avoid operational errors.

Eliminate the influence of external environmental factors in a timely manner, such as temperature, humidity, dust etc.

When equipment fails, Contact the manufacturer or professional maintenance personnel promptly for repairs.

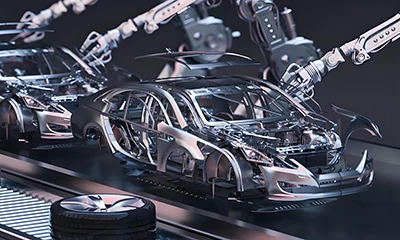

Our CNC machining services have been praised by global customers from different fields, We supply CNC machining components to a variety of industries,Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.