Metal bending

Serve

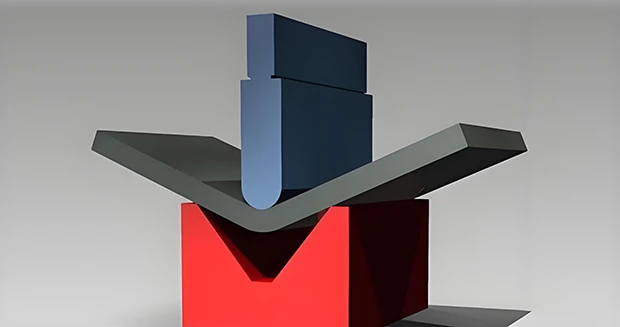

Metal bending is a plastic deformation of metal materials through external forces, Processing methods to form specific shapes. in industrial production, Metal bending is widely used to manufacture various parts, Structural parts and decorations.

One-off CNC machining prototype

Our metal bending capabilities

Choose Rapidefficient Metal Bending, Because of its many advantages. It has high-precision bending technology, Can ensure accurate product size, Meet various stringent requirements. High-efficiency processing flow greatly shortens the production cycle, Increase production capacity. at the same time, Strong adaptability to a variety of metal materials, And it can ensure the stable performance of the material after bending. Professional team provides quality services, Advanced equipment ensures reliable quality, Is your ideal choice in the field of metal bending processing, Help your products stand out in the market.

Metal bending is a metal processing process, By applying external force to metal materials, cause plastic deformation, Thereby changing its shape into a component with a certain bending angle or curvature.

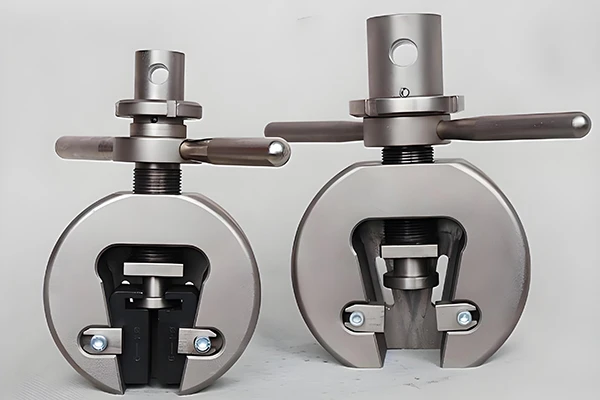

Metal bending often uses specialized bending equipment, Such as bending machine, Plate rolling machine, etc., during the bending process, The crystal structure inside the metal material will slip and reorganize, to adapt to external forces. Different metal materials have different bending properties, It depends on the hardness of the material, strength, Characteristics such as ductility.

Metal bending is widely used in various fields, such as building, Machinery manufacturing, automobile manufacturing, Aerospace, etc., For example, in construction, steel beam, Structural parts such as steel columns often require bending processing, To meet the requirements of architectural design; in machinery manufacturing, Various shaft types, Parts such as pipe fittings also need to be bent, to achieve specific functions。

Building structural parts processing

Steel beams and columns bending: Can bend steel into various steel beams required for construction, steel column shape, Meet the load-bearing and support requirements of the building structure, such as large commercial buildings, Beams and columns in the frame structure of an industrial plant.

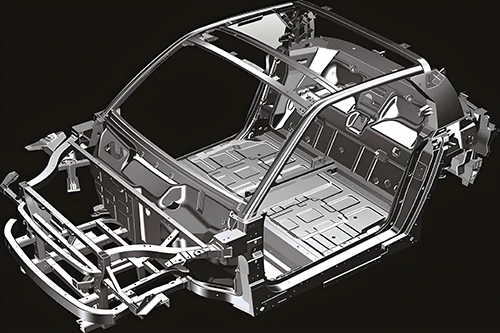

Auto parts manufacturing

Body frame parts bent: Bending sheet metal, Manufacture of various beams for automobile body frames, Columns and other structural parts, Ensure the strength and rigidity of the car body, like a car, Side beams of SUV and other bodies, roof beam.

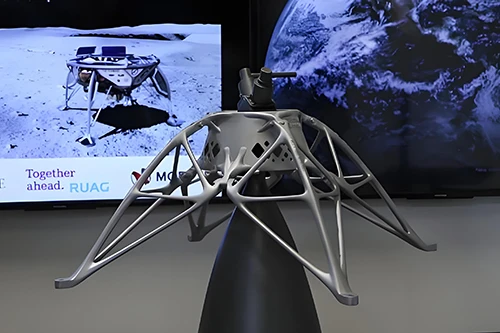

Aerospace field

Aircraft wing and fuselage structural parts bend: Able to accurately bend metal materials such as high-strength aluminum alloy into aircraft wings, The shape of key structural components such as fuselage frames, Ensure aircraft flight performance and structural safety, For example, Boeing, Wing beams and other components of Airbus and other aircraft.

Home appliance manufacturing

Refrigerator, Washing machine casing bent: Bend sheet metal into a refrigerator, The shape of the casing of home appliances such as washing machines, Make it look beautiful and meet structural strength requirements, Provide good appearance and protection for home appliances.

Electronic equipment manufacturing

Computer case and shell bending: Bend metal materials into computer cases, Laptop casing and other shapes, Meet the heat dissipation of electronic equipment, Protection and design requirements, Adapt to the thinness and lightness of modern electronic devices, High-performance development trends.

Industrial piping system

Various pipe elbow bends: Can bend metal pipes efficiently, create different angles, Elbows with different curvature radii, Used to connect different parts in a piping system, Ensure smooth fluid delivery in piping systems, Widely used in chemical industry, oil, Pipe laying for natural gas and other industries.

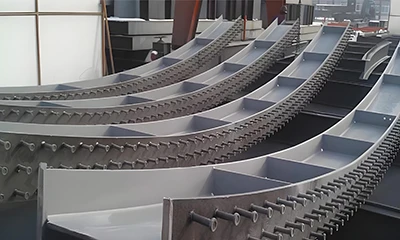

In the metal bending parts display area, Various exquisite parts are eye-catching. There are unique car frame parts, Demonstrating the charm of high-precision bending technology. There are also strong building structural components, Highlighting the importance of metal bending in large-scale projects. From electronic equipment enclosures to industrial pipe elbows, These parts demonstrate the versatility and practicality of metal bending. They are not only industrial products, It is the perfect combination of art and technology, Demonstrating the infinite possibilities that metal bending technology brings to various industries.

1. Various shapes: Metal can be bent into various shapes according to different needs, such as round, arc, Right angle etc., Meet the design requirements of different products. For example, in furniture manufacturing, Metal pipes can be bent into unique shapes, Increase the beauty and artistry of furniture.

2. Flexible size: Can be based on specific application scenarios, Bending metal to different sizes. Whether it is small precision parts, Or a large structural part, Customized production can be achieved through metal bending. For example, in construction, Can be based on the design requirements of the building, steel beam, Metal components such as steel columns are bent into specific sizes and shapes.

1. Reasonable distribution of stress: Metal bending can make the stress distribution of the material more reasonable, Improve the load-bearing capacity of the structure. For example, under bridge construction, By bending steel beams into arch shapes, Can effectively distribute the weight of the bridge, Enhance bridge stability and safety.

2. Reduce material waste: Compared with other processing methods, Metal bending allows for better utilization of material properties, Reduce material waste. For example, When manufacturing cylindrical tanks, By bending sheet metal into a cylindrical shape, Can maximize the use of materials, Reduce the generation of leftover materials.

1. High degree of automation: Modern metal bending equipment usually has a high degree of automation, Can be achieved quickly, Precise bending. For example, CNC bending machines can be programmed to achieve automated operations, Greatly improved production efficiency.

2. Short processing cycle: The metal bending process is relatively simple, Short processing cycle, Can quickly meet customer needs. For example, When manufacturing auto parts, The use of metal bending technology can greatly shorten the production cycle, Improve the competitiveness of enterprises.

Determine needs

1. Identify the type of metal material to be bent, such as steel, Aluminum, Copper materials, etc., The properties of different materials affect the bending process.

2. Determine shape and size requirements for bends, including bending angle, radius of curvature, etc.

Choose the right equipment and tools

1. Select appropriate bending equipment based on material and bending requirements, Such as bending machine, Plate rolling machine, Pipe bending machine, etc.

2. Prepare the corresponding mold, The shape and size of the mold should match the desired bend shape.

Material preparation

1. Check the quality of metal materials, Make sure there are no cracks, Defects etc.

2. Cut materials as needed, blanking, Make it sized to meet bending requirements.

Perform bending operations

1. Place metal materials on the device, Correctly positioned and secured.

2. Set equipment parameters according to material and bending requirements, such as pressure, speed etc.

3. Start the device for bending operation, Pay attention to the deformation of the material during the process, Make sure the bend meets requirements.

Quality check

1. Check whether the dimensions of the bent metal parts meet the requirements, Are the angles and radius of curvature accurate.

2. Check if there are any cracks on the surface, Defects such as wrinkles.

3. if necessary, Make further adjustments or corrections.

Post-processing

1. Deburr bent parts as needed, Surface treatment such as grinding.

2. Anti-rust treatment for parts, Extend service life.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential.

Inaccurate bending angle

Performance: There is a deviation between the actual bending angle and the angle required by the design.

reason: Equipment accuracy issues, Mold wear, Material rebound, etc.

Solution

Regularly inspect and calibrate equipment, Ensure equipment accuracy.

Replace worn molds promptly.

According to the rebound characteristics of the material, Properly adjust the bending angle.

Cracks appear at bends

Performance: Small cracks appear in metal bends.

reason: Improper material selection, Bending radius is too small, Bending speed is too fast, etc.

Solution

Choose the right material, Ensure material toughness and ductility meet bending requirements.

Increase bend radius, Avoid material breakage due to too small bending radius.

Reduce bending speed, Give the material enough time to deform.

Poor surface quality

Performance: There are scratches on the bent metal surface, indentation, Wrinkles, etc.

reason: Rough mold surface, Improper operation, The friction between the material and the mold is too large, etc.

Solution

Polish the mold, Improve mold surface finish.

Standardize operating procedures, Avoid damage to the material surface during the bending process.

Add lubricant between material and mold, reduce friction.

Dimensional deviation

Performance: The size of the bent metal part does not match the design size.

reason: measurement error, Material deformation, Equipment accuracy is not enough, etc.

Solution

Use precise measuring tools, Reduce measurement errors.

Preprocess the material, Reduce material deformation during bending.

Improve equipment accuracy, Ensure the accuracy of processing dimensions.

Our CNC machining services have been praised by global customers from different fields, We supply CNC machining components to a variety of industries,Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.