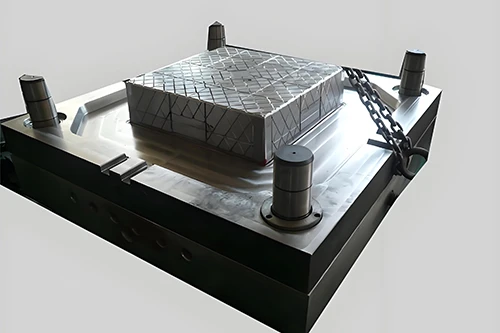

Injection mold

Serve

Injection molding is a method of injecting molten plastic material into the mold cavity through high-pressure injection, Processing method for obtaining products with specific shapes after cooling and solidification.

One-off CNC machining prototype

Efficient production

Manufacturing precision

Cost effective

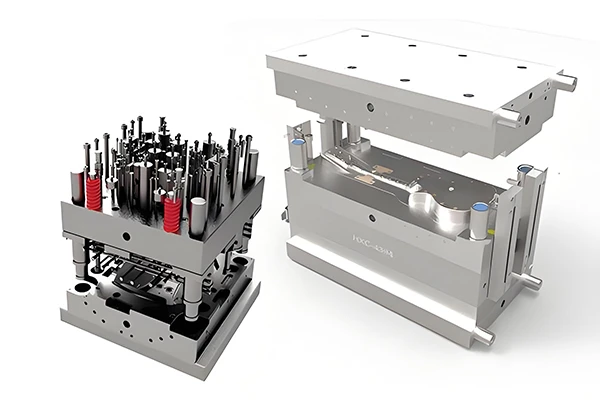

Our injection mold capabilities

Choose Rapidefficient Injection Molds, There are three reasons. one, Efficient production,Can quickly complete the injection molding cycle, Meet the market’s demand for rapid supply of products, Especially suitable for urgent orders. Second, Reliable quality, High-precision manufacturing ensures accurate product dimensions, Exquisite appearance,Stable performance. Third, Cost effective, Although the initial investment is higher, But in the long run, High productivity and low scrap rates reduce overall costs, Bring greater profit margins to enterprises, is to achieve high quality, Ideal for high-efficiency production.

Injection molding is a method of injecting heated and melted plastic material into a specific mold cavity, The process of obtaining plastic products of specific shapes after cooling and solidification. Apply pressure through the injection molding machine, Fill the mold with plastic, Molding under precisely controlled temperature and pressure. Can produce complex shapes, High-precision products, Widely used in automobiles, electronic, Medical and many other fields, Able to achieve efficient mass production, Meet the needs of different industries for plastic products, It is one of the important processing methods in modern manufacturing industry.

Working principle

The injection molding machine pushes the plastic particles forward through the rotation of the screw, and heated and melted in a heating cylinder. When the plastic reaches a certain molten state, The injection device of the injection molding machine injects molten plastic into the mold cavity at high pressure. during the injection, The movable mold and the fixed mold of the mold are tightly closed, Provide sufficient clamping force, Prevent plastic spillage.

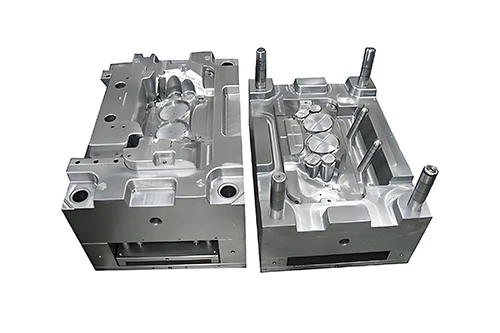

The mold is mainly composed of two parts: the movable mold and the fixed mold. The movable mold is installed on the moving platen of the injection molding machine, The fixed mold is installed on the fixed template. When the injection molding machine closes the mold, The movable mold and the fixed mold are closely matched, Form a closed mold cavity.

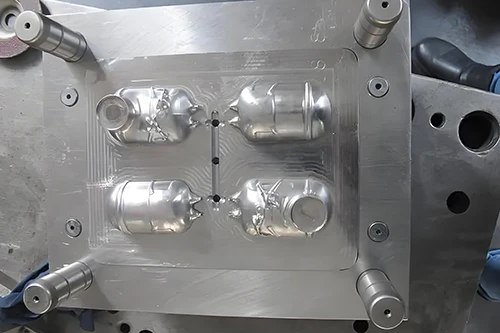

The pouring system is an important part of the mold, including main channel, Runners and gates, etc. The main channel is the channel that connects the nozzle and runner of the injection molding machine, Introducing molten plastic into the mold. Split channels distribute plastic evenly to each cavity. The gate is the entrance for plastic to enter the mold cavity, Its shape and size have a significant impact on plastic flow and product quality.

Temperature control system is used to control the temperature of the mold, Make sure the plastic cools and solidifies at the right temperature. Molded parts are the parts that are in direct contact with plastic, Determines the shape and size of the product. Structural parts play the role of supporting and fixing the mold.

Auto parts

1. bumper: Car bumpers formed by injection molding have high strength, Impact resistance and good appearance. Can be based on the design requirements of different models, Custom bumpers of various shapes and sizes.

2. Dashboard: Injection molded dashboard housing enables complex shapes and textures, While ensuring good dimensional accuracy and surface quality. The mounting holes for various instruments and control buttons on the instrument panel can also be precisely processed through molds.

Electronic equipment housing

1. mobile phone case: Injection molded mobile phone cases can be made thin and light, Beautiful design, While ensuring good strength and wear resistance. Can be based on the requirements of different mobile phone brands and models, Customized mobile phone cases in various colors and surface treatments.

2. computer case: Injection molded computer case casing can achieve good heat dissipation and protection properties, While ensuring good dimensional accuracy and appearance quality. Can be customized according to different computer configurations and user needs, Customized computer cases of various sizes and functions.

Household items

1. plastic chair: Injection molded plastic chair features lightweight, solid, Durable features, Can be based on different usage scenarios and user needs, Customized chairs in various shapes and colors.

2. plastic storage box: Injection molded plastic storage boxes can achieve good sealing and moisture-proof properties, While ensuring good dimensional accuracy and appearance quality. Can be adapted to different storage needs and space sizes, Customized storage boxes of various sizes and functions.

Medical equipment and consumables

1. syringe: Injection mold molded syringes with high precision, High sealing and good biocompatibility, Can be based on different medical needs and drug specifications, Customized syringes of various volumes and shapes.

2. infusion set: Infusion sets formed by injection molding have good flow control performance and safety, Can be based on different infusion needs and patient conditions, Customized infusion sets with various specifications and functions.

Toy

1. plastic building blocks: Injection molded plastic building blocks allow for various combinations of shapes and colors, While ensuring good strength and safety. Can be adapted to the needs of children of different ages, Customized building block toys of various difficulties and themes.

2. plastic doll: Injection molded plastic figures enable realistic appearance and motion design, While ensuring good strength and durability. Can be based on different animations, Movie and game characters, Customized doll toys of various shapes and sizes.

Packaging products

1. plastic bottle: Injection molded plastic bottles can be designed in various shapes and capacities, While ensuring good sealing and corrosion resistance. Can be customized according to different product packaging needs, Customized plastic bottles in various colors and surface treatments.

2. plastic bottle caps: Injection molded plastic bottle caps can achieve good sealing and opening performance, While ensuring good dimensional accuracy and appearance quality. Can be customized according to different plastic bottle specifications and uses, Customized bottle caps in various shapes and colors.

In order to let you intuitively feel our CNC machining strength, Here are some of our past project results, and demonstration components carefully designed by professional engineers. Our team has demonstrated exceptional flexibility with all types of CNC machined components. so, If you are looking for a CNC machining company for your project, Then you don’t have to run around anymore!

1. high speed: Injection molding machines can complete an injection molding cycle in a short time, Produce plastic products quickly. Once the mold is installed and debugged, can produce continuously, Greatly improved production efficiency.

2. High degree of automation: The injection molding process can be highly automated, From the transportation of plastic raw materials, heating, From injection molding to product demoulding, Packaging and other aspects can be completed through automated equipment. This not only reduces manual operations, Reduce labor intensity, Also improves production stability and consistency.

3. Suitable for mass production: Injection molding is ideal for mass production, A large number of plastic products of the same specifications can be produced in a short period of time. This is very important to meet the huge demand for plastic products in the market.

1. High dimensional accuracy: Injection molds can produce plastic products with very high dimensional accuracy. The manufacturing accuracy of molds can usually reach the micron level, By precisely controlling injection molding process parameters, It can ensure that the dimensional tolerance of plastic products is controlled within a very small range. This is suitable for some products that require higher dimensional accuracy, such as electronic equipment casings, Auto parts, etc., very important.

2. complex shape: Injection molds can produce plastic products with very complex shapes. The mold can be made according to the design requirements of the product, Create various complex cavity structures, To achieve complex shapes of plastic products. This provides greater freedom in product design, Able to meet the personalized needs of different customers.

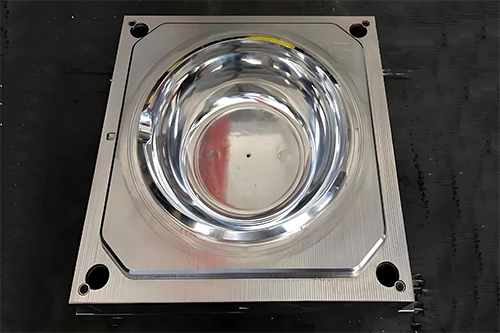

3. Good surface quality: Injection molds can produce plastic products with very good surface quality. The cavity surface of the mold is finely machined and polished, Can make the surface of plastic products smooth, flawless, Uniform color. This is suitable for some products that have higher requirements on appearance, Such as cosmetic packaging, toys etc., very important.

1. High material utilization rate: Injection molding is a non-cutting process, Material utilization rate is very high. During the injection molding process, The plastic raw material is heated and melted and then directly injected into the mold cavity for molding, Almost no material waste. In comparison, Some traditional processing techniques, such as machining, Stamping etc., Will produce a lot of leftovers and waste, Low material utilization rate.

2. Low production cost: Due to the high production efficiency of injection molding, High precision, High material utilization rate, Therefore the production cost is relatively low. on the one hand, High production efficiency can reduce the production cost of unit products; on the other hand, High-precision manufacturing reduces subsequent machining and trimming operations, Reduce processing costs. also, Injection molding can also realize automated production, Reduce labor costs.

3. Long mold life: High-quality injection molds usually have a long service life, A large number of plastic products can be produced. Although the initial investment in molds is higher, But the cost allocated to each product is very low. This is for long-term production of plastic products, It is a very economical and effective production method.

Design stage

1. Clarify product requirements:

Determine the use of plastic products, Performance requirements, Dimensions, Appearance requirements, etc.

Communicate fully with clients or design teams, Ensure there is a clear understanding of product requirements.

2. product design:

Product design using professional CAD software, Consider the characteristics of plastic materials and the limitations of the molding process.

Pay attention to wall thickness uniformity when designing, avoid sharp corners, Set a reasonable demoulding slope, etc., To ensure that the product can be smoothly released from the mold.

3. Mold design:

According to product design, Carry out mold design. The mold should include a cavity, core, Gating system, cooling system, Release mechanism and other parts.

Choose the right mold material, Ensure mold strength and durability. at the same time, Consider the processing difficulty and cost of the mold.

Material selection

1. According to product performance requirements and usage environment, Choose the right plastic material. Common plastic materials include polyethylene (PE), Polypropylene (PP), Polystyrene (PS), Polyvinyl chloride (PVC), ABS etc.

2. Consider the fluidity of plastic materials, Shrinkage, heat resistance, Corrosion resistance and other performance parameters, To ensure product quality after molding.

Mold making

1. Choose the right mold manufacturing process:

Traditional machining can be used, EDM and other processes, Advanced CNC machining can also be used, 33D printing and other technologies.

According to the complexity of the mold and production batch, Choose the most economical, Efficient manufacturing process.

2. Strictly control mold manufacturing accuracy:

The manufacturing accuracy of the mold directly affects the quality of the product after molding. during the manufacturing process, Dimensional tolerances must be strictly controlled, Surface roughness and other parameters.

Use high-precision processing equipment and testing methods, Ensure the quality of the mold meets the requirements.

Injection molding

1. Prepare injection molding machine and plastic materials:

Choose the right injection molding machine, Determine the specifications and parameters of the injection molding machine based on the size and weight of the product.

Drying plastic materials, Remove moisture and impurities, Ensure material performance is stable.

2. Debugging injection molding process parameters:

including injection pressure, injection speed, temperature, Time and other parameters. Passed mold trial, Continuously adjust process parameters, To obtain the best molding effect.

Pay attention to problems during the molding process, Like flying edge, shrink, Bubbles etc., Take timely measures to solve the problem.

Post-processing stage

1. Remove gates and flash:

Use tools to remove gates and flash from the molded product, Make the product surface smooth and tidy.

Be careful not to damage the surface quality of the product.

2. Inspection and packaging:

Inspection of molded products, Check dimensional accuracy, appearance quality, Whether performance meets the requirements.

Qualified products for packaging, for transportation and storage.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential

Product defect issues

1. Sink Marks

Performance: Local dents appear on the product surface.

reason: Plastic shrinks unevenly during cooling, Usually due to uneven wall thickness, Insufficient injection pressure, Caused by insufficient holding time or too high mold temperature.

Solution: Optimize product design, Make the wall thickness as uniform as possible; Increase injection pressure and holding time; Adjust mold temperature.

2. Flash

Performance: Excess plastic appears on the parting surface or mold gap of the product.

reason: The mold is not closed tightly, Injection pressure is too high, Plastic fluidity is too good, etc.

Solution: Check the sealing of the mold, Adjust mold clamping force; Reduce injection pressure; Choose plastic materials with moderate flow.

3. Voids

Performance: Holes appear inside the product.

reason: Moisture or volatiles in the plastic vaporize during the injection process, Or the injection speed is too fast and the air cannot be discharged.

Solution: Drying plastic raw materials; Reduce injection speed, Add vents.

4. Warpage

Performance: The product is deformed, Uneven.

reason: Uneven cooling, Plastic shrinks inconsistently, Unreasonable product structure design, etc.

Solution: Optimize mold cooling system; Adjust plastic shrinkage; Improve product design.

Process issues

1. Short Shot

Performance: Product does not completely fill the mold cavity.

reason: Insufficient injection pressure, Injection speed is too slow, Plastic has poor fluidity, Gate size is too small, etc.

Solution: Increase injection pressure and speed; Improve the flowability of plastics; Expand gate size.

2. Flow Marks

Performance: Traces similar to water flow appear on the surface of the product.

reason: The temperature of the plastic is uneven during the flow process, Injection speed is unstable, Rough mold surface, etc.

Solution: Adjust injection process parameters, Ensure plastic temperature is even; Stable injection speed; Polish the mold.

3. Discoloration

Performance: The color of the product is not as expected.

reason: Plastic decomposition by overheating, Pigments are unevenly dispersed, Mold temperature is too high or too low, etc.

Solution: Reduce the heating temperature of plastics; Ensure pigments are fully dispersed; Adjust mold temperature.

Equipment issues

1. Mold wear

Performance: Parting surface of mold, Wear in parts such as the cavity, Affect product quality.

reason: long term use, plastic friction, Poor mold material quality, etc.

Solution: Carry out regular maintenance and upkeep on molds; Choose high-quality mold materials; Optimize the injection molding process, Reduce mold wear.

2. Injection molding machine failure

Performance: Various malfunctions occur in injection molding machines, Such as injection system failure, Hydraulic system failure, Electrical system failure, etc.

reason: Equipment aging, Improper operation, Maintenance is not timely etc.

Solution: Regularly maintain and inspect injection molding machines; Strengthen operator training; Replace damaged parts promptly.

design complexity

1. Product structure is complex: Modern product design increasingly pursues multi-function, Miniaturization and lightweight, This requires injection molds to cope with complex product structures. For example, With internal undercut, thin wall structure, Products with features such as fine texture, Putting forward higher requirements for mold design and manufacturing.

2. Multi-material combination: To meet different performance needs, Many products are made from a variety of plastic materials or combined with other materials such as metal, Rubber, etc.) combination. This increases the difficulty of mold design, Shrinkage rates of different materials need to be considered, Liquidity, Factors such as combination methods.

3. Mold structure optimization: In order to improve production efficiency and product quality, Mold needs structural optimization. For example, Proper design of cooling system, Gating system, Mold release mechanism, etc., To ensure that the plastic cools evenly within the mold, Quick filling and smooth demoulding. This requires rich experience and advanced design software support.

Material selection and handling

1. Material performance diversity: Various types of plastic materials, Each material has its own unique performance characteristics, such as liquidity, Shrinkage, heat resistance, Corrosion resistance, etc., Choosing the right material requires comprehensive consideration of the product’s use environment, Performance requirements, Cost and other factors. also, Material properties may vary from batch to batch, This also brings certain uncertainty to production.

2. Material recycling and environmental protection: With the increasing awareness of environmental protection, The recycling and reuse of plastic materials is receiving increasing attention. However, The performance and quality of recycled materials are often not as stable as new materials, This brings challenges to mold molding. at the same time, How to ensure product quality on the premise of, Increase the use of recycled materials, It is also a problem that needs to be solved.

3. Material handling difficulty: Some high-performance plastic materials, Such as engineering plastics, Special plastics, etc., Requires special handling methods during processing, such as dry, preheat, Insulation, etc., This increases the complexity and cost of production, At the same time, it also puts forward higher requirements for equipment and operators.

Process control and optimization

1. Many process parameters: Injection molding involves multiple process parameters, Such as injection pressure, injection speed, temperature, time etc. These parameters influence each other, Reasonable adjustments and optimizations are needed, to get high quality products. Determining the optimal combination of process parameters requires extensive testing and data analysis, This is a complex and time-consuming process.

2. Difficulty in quality control: The quality of plastic products is easily affected by many factors, Such as mold wear, Material changes, Process parameter fluctuations, etc., therefore, Need to establish strict quality control system, Real-time monitoring and testing of products, Detect and solve quality problems promptly. However, Quality control is more difficult, Requires the use of advanced testing equipment and technology.

3. Production efficiency and cost: Improving production efficiency and reducing costs are important goals for injection molding. However, This often requires process parameters, Mold design, Trade-offs and optimization in material selection and other aspects. For example, Increasing injection speed can shorten production cycle, But it may cause product quality problems; Choosing low-cost materials can reduce costs, But it may affect product performance. therefore, Need to find a balance point, To achieve the best combination of production efficiency and cost.

Market competition and innovation

1. Market competition is fierce: The injection molding industry is highly competitive, Enterprises need to continuously improve product quality, Reduce costs, Shorten delivery time, to meet customer needs. at the same time, As technology continues to advance, new materials, Processes and equipment continue to emerge, Businesses need to constantly innovate and improve,to stay competitive.

2. Product innovation needs: As the market continues to change and consumer demands continue to increase, The demand for innovation in plastic products is also increasing. Enterprises need to continuously develop new product designs, Functions and applications, to meet market needs. This requires enterprises to have strong R&D capabilities and innovation awareness, At the same time, it is also necessary to communicate with customers, Cooperation with suppliers, Jointly promote product innovation.

Our CNC machining services have been praised by global customers from different fields。We supply CNC machining components to a variety of industries,Covers the following and more

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.