Aluminum extrusion

Serve

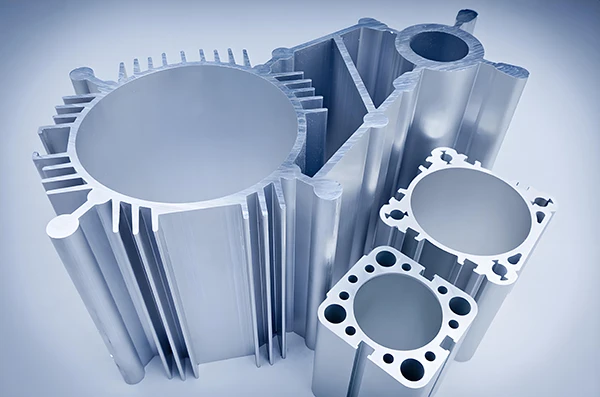

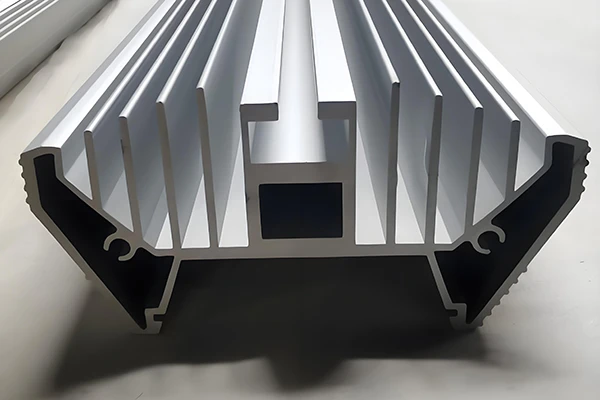

Aluminum extrusion is a processing method in which aluminum alloy materials are extruded into the desired shape through a die at high temperatures.

One-off CNC machining prototype

Our aluminum extrusion parts capabilities

Rapidefficient aluminum extrusions may be chosen because: Various shapes can be customized, Excellent performance and high strength, Advantages of high production efficiency and moderate cost.

Aluminum extrusion is a processing method in which aluminum alloy materials are extruded into the desired shape through a die at high temperatures. This technology can produce aluminum profiles with complex cross-sections and high precision, Widely used in various industrial products. Aluminum extrusion can not only improve material utilization, It can also significantly improve the performance and appearance quality of the product.

Aluminum alloy types for aluminum extrusion

6061Aluminum alloy: Has good mechanical properties and corrosion resistance, Suitable for manufacturing structural parts, bridge, Bicycle frames etc.

6063Aluminum alloy: Has excellent surface treatment properties and good solderability, Widely used in building doors and windows, Decorative materials, etc.

Building door and window frame processing

Can accurately extrude door and window frame profiles of various shapes, High strength, Accurate, Meet the diverse needs of buildings.

Auto parts manufacturing

Specializing in the production of aluminum parts for automobiles, such as bumper, Heat dissipation components, etc., Lightweight and reliable.

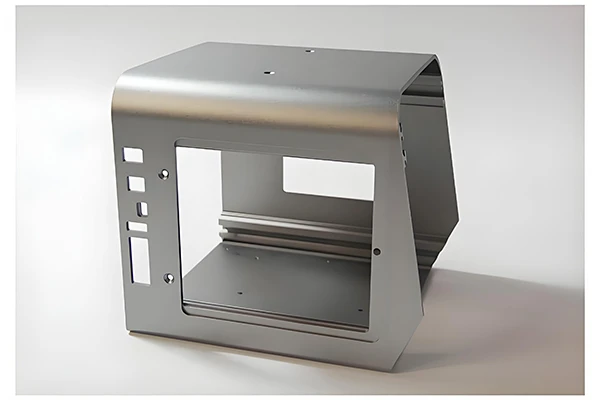

Electronic equipment housing processing

Capable of manufacturing high-precision electronic equipment casings, such as mobile phone, Computer case, Both beautiful and good heat dissipation.

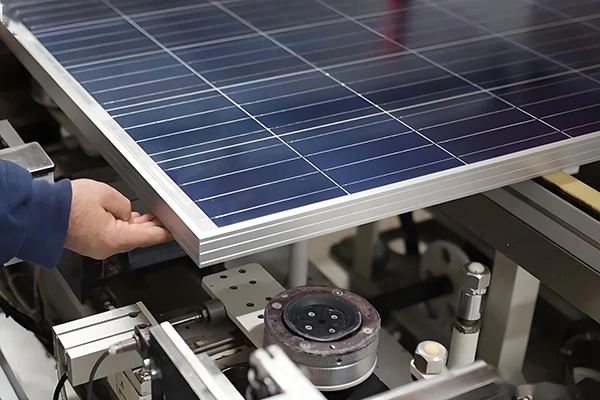

Solar frame production

Provide high quality aluminum frames for solar panels, regular shape, Strong corrosion resistance, Suitable for various specifications of solar panels.

Rail transit parts processing

Can process high-speed rail, Parts for subway and other rail transit, such as screen door frame, Strength and precision meet industry standards.

Furniture decorative profile manufacturing

Specialized in creating aluminum profiles for furniture decoration, table and chair frame, Decorative lines, etc., Beautiful and durable, Various styles.

ppreciate the charm of aluminum machined parts, The perfect combination of craftsmanship and design is presented here.

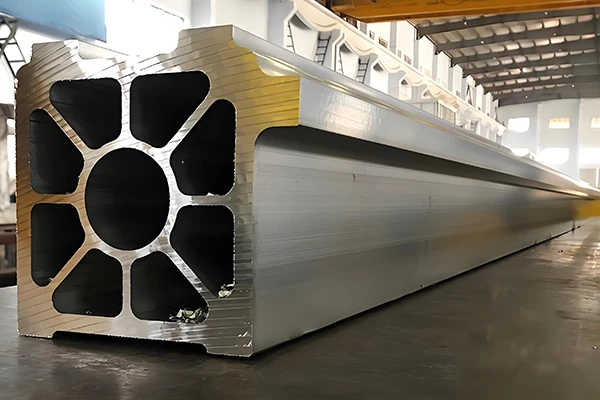

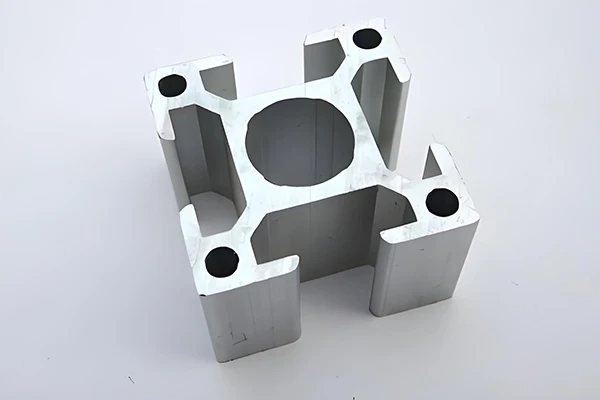

Can extrude complex shapes, Meet different design needs. Such as various special-shaped pipes, Provide more possibilities for architectural and industrial design.

Properly processed, As strong as steel. for mechanical structures, Can withstand larger loads, Ensure stable operation of equipment.

Abundant raw materials and high processing efficiency, Reduce production costs. Conducive to large-scale application, Save money for your business.

Clarify needs

Determine the exact specifications of the parts needed, including size, shape, Accuracy requirements, etc., Consider the function and use environment of the part in the product.

Choose the right aluminum alloy

Select the appropriate aluminum alloy grade according to the performance requirements of the part. Different grades of aluminum alloys have different strengths, Corrosion resistance and other properties.

Design and mold making

1. When designing parts, Fully consider the process characteristics of aluminum extrusion, Avoid difficult-to-machine structures. Reasonable design of wall thickness, Reinforcement ribs, etc.

2. Make high quality molds, The accuracy of the mold directly affects the quality of the parts.

Extrusion processing

1. Place the heated aluminum alloy billet into the extruder, Extrusion of the required shape of the part through the die.

2. Control extrusion speed, Parameters such as temperature and pressure, Ensure part quality and dimensional accuracy.

Follow-up processing

1. Quenching extruded parts, Aging and other heat treatments, Improve the strength and hardness of parts.

2. Surface treatment as needed, such as anodizing, Spraying, etc., Improve corrosion resistance and aesthetics of parts.

Quality inspection

1. Dimensional measurement of finished parts, Appearance inspection, Mechanical property testing, etc., Ensure parts meet quality requirements.

2. Use measuring tools, microscope, Hardness tester and other testing equipment, Comprehensive inspection of parts.

Packaging and storage

Use appropriate packaging, Prevent parts from being damaged during shipping and storage. Storage environment should be dry, clean,Avoid parts getting wet, corrosion.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential.

Surface defects: such as scratches, peeling, Pockets, etc.

Reason: Rough mold surface, Extrusion speed is too fast, Unclean working environment, etc.

Solution

Improve mold surface quality, Polish and maintain molds regularly.

Optimize extrusion speed, Avoid going too fast or too slow.

Keep your work environment clean, Reduce the impact of impurities on the surface of parts.

Dimensional deviation: Actual size does not match design size

Reason: Mold wear, Extrusion temperature is unstable, Equipment accuracy issues, etc.

Solution

Regularly inspect and replace molds, Ensure mold dimensional accuracy.

Stable extrusion temperature, Adopt precise temperature control system.

Perform regular maintenance and calibration of equipment, Improve equipment accuracy.

Insufficient mechanical properties: strength, Hardness cannot meet the requirements

Reason: Improper alloy selection, Unreasonable heat treatment process, etc.

Solution

Select the appropriate aluminum alloy grade according to the performance requirements of the part.

Optimize heat treatment process, Ensure that the mechanical properties of the alloy are fully utilized.

Deformation: Parts deformed during processing or use

Reason: Extrusion process parameters are unreasonable, Uneven cooling, Insufficient stress relief, etc.

Solution

Optimize extrusion process parameters, Such as extrusion ratio, Extrusion speed, etc., Reduce internal stress in parts.

Adopt uniform cooling method, Avoid local overheating or cooling.

Proper stress relief of parts, Such as annealing, etc.

Our CNC machining services have been praised by global customers from different fields, We supply CNC machining components to a variety of industries, Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.