In the field of manufacturing, precision machining of mold parts plays a crucial role. Mold parts are essential components in various industries, such as automotive, electronics, and packaging. The quality and precision of these parts directly affect the performance and quality of the final products. In this article, we will explore the precision machining technology and process for mold parts and highlight the value of rapidefficient in the CNC machining market.

I. Introduction to Mold Parts and Their Importance

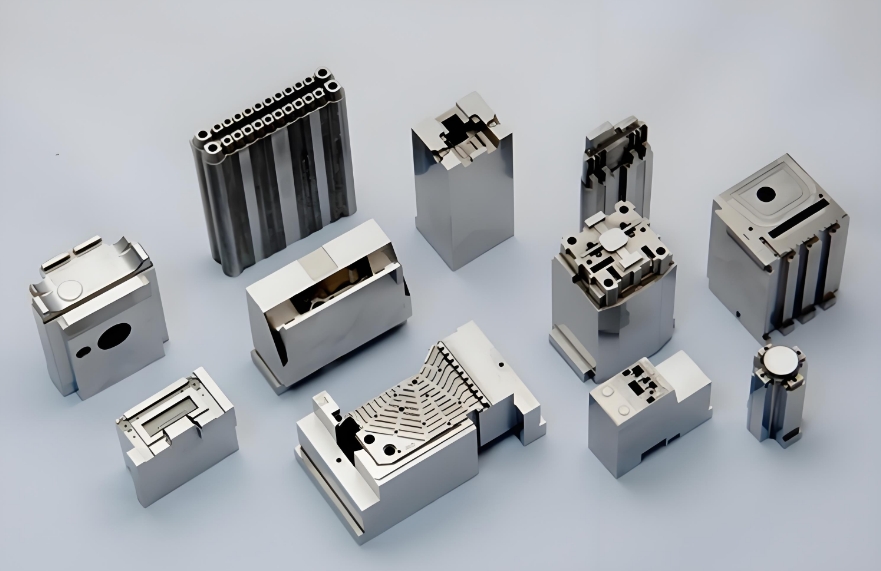

Mold parts are used to shape and form materials into specific shapes and sizes. They are made of high-quality materials such as steel, aluminum, and copper alloys. Mold parts can be classified into different types, including injection molds, compression molds, and extrusion molds. Each type of mold has its own unique characteristics and applications.

The importance of precision machining for mold parts cannot be overstated. High-precision mold parts ensure the accuracy and consistency of the molded products, reducing defects and improving product quality. Additionally, precision machining can increase the production efficiency and reduce production costs by minimizing the need for rework and adjustments.

II. Precision Machining Technologies for Mold Parts

- CNC Machining

CNC (Computer Numerical Control) machining is one of the most widely used precision machining technologies for mold parts. It uses computer-controlled machines to remove material from a workpiece with high accuracy and repeatability. CNC machining can produce complex geometries and tight tolerances, making it ideal for mold parts with intricate designs.

- Electrical Discharge Machining (EDM)

EDM is a process that uses electrical discharges to remove material from a workpiece. It is particularly useful for machining hard materials and complex shapes that are difficult to machine using traditional methods. EDM can achieve high precision and surface finish, making it suitable for mold parts that require tight tolerances.

- Wire EDM

Wire EDM is a variation of EDM that uses a thin wire electrode to cut through the workpiece. It is capable of producing extremely accurate and complex shapes with minimal distortion. Wire EDM is often used for machining high-precision mold parts with fine details.

- Grinding

Grinding is a process that uses abrasive wheels to remove material from a workpiece. It is used to achieve high surface finish and dimensional accuracy. Grinding is commonly used for finishing mold parts to ensure smooth surfaces and tight tolerances.

III. Precision Machining Process for Mold Parts

- Design and Engineering

The first step in the precision machining process for mold parts is design and engineering. A detailed design of the mold part is created using computer-aided design (CAD) software. The design takes into account the functionality, dimensional requirements, and material properties of the part.

- Material Selection

The selection of the appropriate material is crucial for the performance and durability of the mold part. Different materials have different properties, such as hardness, strength, and heat resistance. The material is chosen based on the specific requirements of the application.

- Machining Operations

Once the design and material are determined, the machining operations can begin. The workpiece is loaded onto the machining center and the appropriate cutting tools are selected. The machining process involves removing material from the workpiece using the selected machining technology, such as CNC machining, EDM, or grinding.

- Inspection and Quality Control

After the machining operations are completed, the mold part is inspected to ensure that it meets the required dimensional tolerances and surface finish. Inspection methods may include coordinate measuring machines (CMMs), optical comparators, and surface roughness testers. Any deviations from the specifications are corrected through additional machining or adjustments.

- Finishing and Assembly

Once the mold part passes inspection, it may undergo additional finishing operations such as polishing, plating, or heat treatment. These operations improve the surface finish, hardness, and corrosion resistance of the part. Finally, the mold part is assembled with other components to form the complete mold.

IV. The Value of Rapidefficient in the CNC Machining Market

Rapidefficient is a leading provider of CNC machining services, specializing in the production of high-precision mold parts. The company offers a wide range of services, including CNC milling, turning, EDM, and grinding. Rapidefficient’s expertise in precision machining and its commitment to quality make it a valuable partner for businesses in various industries.

High-Quality Products

Rapidefficient uses state-of-the-art machining equipment and advanced manufacturing processes to ensure the highest quality of its products. The company’s strict quality control measures guarantee that every mold part meets the exact specifications and requirements of its customers.

Fast Turnaround Times

Rapidefficient understands the importance of time in the manufacturing process. The company offers fast turnaround times without sacrificing quality. Its efficient production processes and streamlined operations enable it to deliver products quickly and meet tight deadlines.

Cost-Effective Solutions

Rapidefficient provides cost-effective solutions without compromising on quality. The company’s competitive pricing and optimized manufacturing processes help businesses reduce production costs and improve their bottom line.

Customization and Flexibility

Rapidefficient works closely with its customers to understand their unique needs and requirements. The company offers customization and flexibility in its services, allowing customers to get exactly what they need. Whether it’s a one-off prototype or a large production run, Rapidefficient can handle it all.

Technical Expertise and Support

Rapidefficient’s team of experienced engineers and technicians provides technical expertise and support throughout the entire manufacturing process. From design and engineering to production and inspection, the company’s experts are available to answer questions and provide solutions.

V. Conclusion

Precision machining technology and process for mold parts are essential for ensuring the quality and performance of molded products. The use of advanced machining technologies and strict quality control measures can result in high-precision mold parts with tight tolerances and excellent surface finish. Rapidefficient is a trusted provider of CNC machining services, offering high-quality products, fast turnaround times, cost-effective solutions, customization, and technical expertise. If you are looking for a reliable and experienced CNC machining service provider for your mold part needs, consider rapidefficient.