Introduction

CNC machine processing plant has revolutionized manufacturing by providing precision, speed, and versatility. Finding a reliable CNC machine processing plant can make or break your production goals. This article delves into the critical factors to consider and highlights why rapidefficient stands out as a trusted partner in this domain.

Understanding CNC Machine Processing

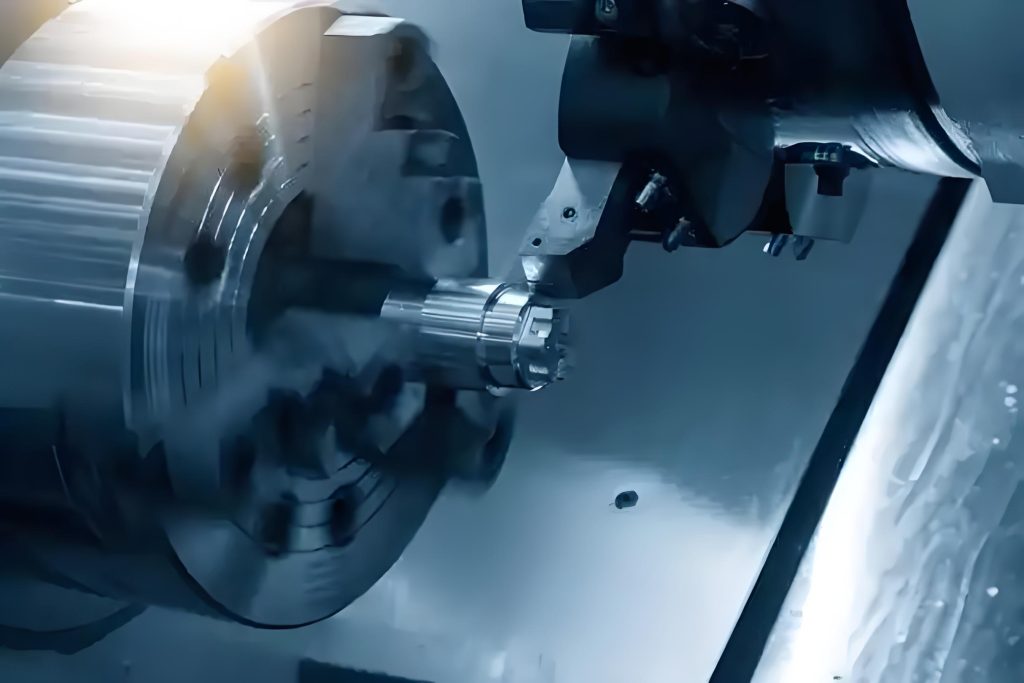

CNC (Computer Numerical Control) machining uses automated controls to operate machinery for manufacturing precision parts. It’s widely applied in industries like aerospace, automotive, electronics, and medical devices. The process includes techniques such as:

- Milling: Creating complex shapes with precision.

- Turning: Producing cylindrical components efficiently.

- Drilling: Making accurate holes for various applications.

- Cutting: Ensuring flawless edges for metal and non-metal materials.

Why Choosing the Right CNC Machine Processing Plant Matters

Selecting the right CNC machine processing plant ensures:

1. High-Quality Outputs

Precision and accuracy are non-negotiable. A reliable plant guarantees:

- Tight tolerances.

- Uniform quality across all parts.

- Use of premium materials.

2. Cost-Effectiveness

A good plant optimizes processes to minimize waste and lower costs while maintaining quality standards.

3. Scalability

From prototyping to large-scale production, a trustworthy partner adapts to your business needs without compromising timelines or quality.

4. On-Time Delivery

Delays in manufacturing can disrupt entire supply chains. Dependable facilities ensure your parts are delivered as promised.

How to Identify a Reliable CNC Machine Processing Plant

Here are actionable tips to help you make the right choice:

1. Evaluate Experience and Expertise

Look for a facility with years of experience and a proven track record in your industry. Expertise in handling diverse materials and complex designs is a bonus.

2. Inspect Certifications and Standards

Ensure the plant adheres to global standards such as ISO 9001 for quality management and ISO 14001 for environmental management.

3. Assess Technological Capabilities

Modern CNC machines with advanced software ensure precision, speed, and versatility. Ask about:

- The range of machines available.

- Support for multi-axis machining.

- Real-time monitoring systems.

4. Request Sample Work

Examine the quality of their past projects. Pay attention to surface finishes, tolerances, and material handling.

5. Check Customer Reviews and References

Positive testimonials and case studies from previous clients indicate reliability and satisfaction.

Why Rapidefficient is Your Ideal CNC Machine Processing Partner

Rapidefficient combines cutting-edge technology with exceptional service to deliver top-tier CNC machining solutions. Here’s what sets them apart:

1. Advanced Equipment

Rapidefficient utilizes state-of-the-art CNC machines capable of multi-axis machining, ensuring unparalleled precision.

2. Skilled Workforce

Their team of experienced engineers and technicians guarantees meticulous attention to detail at every production stage.

3. Custom Solutions

From prototypes to large-scale production runs, rapidefficient offers tailored services to meet your unique requirements.

4. Sustainability Practices

Rapidefficient prioritizes eco-friendly processes, aligning with global efforts to reduce carbon footprints.

Conclusion

Finding a reliable CNC machine processing plant requires careful evaluation of expertise, technology, and quality standards. Rapidefficient excels in all these aspects, making them the ideal partner for your CNC machining needs. With their commitment to precision, efficiency, and sustainability, rapidefficient ensures your projects are in capable hands.

Ready to elevate your manufacturing processes? Contact rapidefficient today to discuss your requirements and experience the difference.