During CNC machining, the rotation direction of the milling cutter is generally fixed, but the feed direction often changes. Climb milling and conventional milling are two common milling methods. So, should climb milling or conventional milling be used during CNC machining?

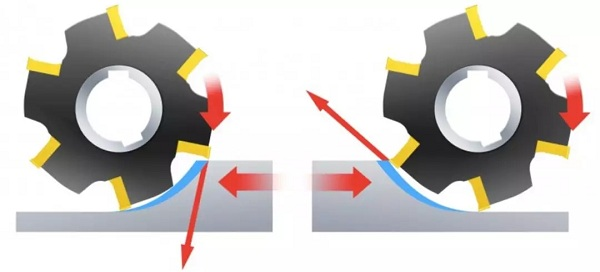

The cutting edge of a milling cutter is subject to impact loads every time it engages the workpiece. Proper contact between the cutting edge and the material must be considered during both entry and exit. During milling, the workpiece is fed either in the same or opposite direction as the milling cutter’s rotation, which determines whether the cut is performed using a down-cut (climb) or up-cut (conventional) method.

1. Milling Principle – From Thick to Thin

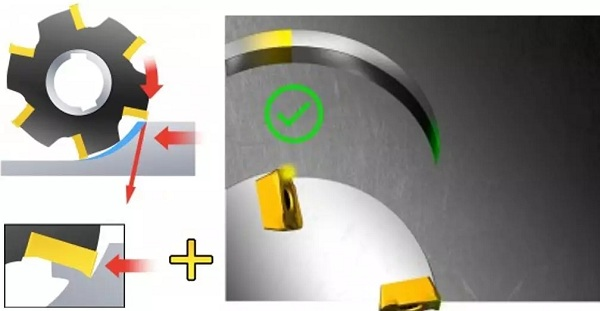

When milling, chip formation is crucial. The principle of cutting is “thick to thin,” ensuring that a thick chip is formed during entry and a thin chip is formed at exit. This helps maintain a stable milling process and reduces the risk of tool deflection or vibration.

2. Climb Milling (Down-Cut Milling)

In climb milling, the cutting tool feeds in the direction of rotation. As long as the machine tool, cutter, and workpiece are properly aligned, climb milling is generally the preferred milling method.

- The chip thickness decreases from the start of the cut, reaching zero at the end of the cut.

- Cutting force tends to pull the workpiece toward the cutter, keeping the cutting edge engaged in the cut.

- Machine backlash must be minimized to prevent the cutter from pulling the workpiece uncontrollably.

Climb milling is typically recommended for high-precision machining and achieving superior surface finish.

3. Conventional Milling (Up-Cut Milling)

During conventional milling, the cutting tool feeds opposite to its rotation. The chip thickness starts at zero and increases to the maximum at the end of the cut.

- Cutting force pushes the cutter away from the workpiece, which can lead to tool vibration.

- Chips may rub against the previously cut surface, causing work hardening and potential surface scratches.

- High cutting forces and uneven chip thickness can reduce tool life.

Conventional milling is usually suitable for roughing or when machining materials sensitive to cutting impact.

4. Part Fixturing

The feed direction influences fixture requirements:

- Climb milling: fixtures must resist downward forces and secure the workpiece firmly.

- Conventional milling: fixtures must resist lifting forces caused by the cutter pushing the workpiece away.

5. Comparison Table – Climb Milling vs Conventional Milling

| Processing Aspect | Climb Milling | Conventional Milling |

|---|---|---|

| Chip Thickness | Large to Small | Small to Large |

| Slippage | Minimal/None | Possible |

| Tool Wear | Slower | Faster |

| Tool Surface Chilling | None | May occur |

| Workpiece Effect | Pressing | Lifting |

| Eliminating Backlash | Not required | Required |

| Vibration | Small | Large |

| Energy Consumption | Lower | Higher (5%-15%) |

| Surface Roughness | Better | Lower |

| Applications | Precision Machining | Roughing |

Summary

Both climb milling and conventional milling have advantages depending on the machining scenario. The choice between the two depends on:

- Workpiece material and hardness

- Machining precision requirements

- Machine tool rigidity and backlash

- Surface finish and productivity considerations

RapidEfficient specializes in high-precision CNC machining with 18 years of experience. Its products cover medical, communications, optics, drones, intelligent robots, automotive, and office automation parts. The company’s CNC machining centers include four-axis, five-axis, and linkage machine tools, and are equipped with precision projectors, three-coordinate measuring machines, spectrometers, and other precision testing equipment. Machining accuracy can achieve 0.01mm, and testing accuracy can achieve 0.001mm.