Injection molds are molds used to form plastic products. Mold design and manufacturing need to consider multiple factors, such as product shape, size and complexity, processing accuracy and production efficiency. During the production process, it needs to go through multiple processing and precision adjustments to ensure the quality and performance of the final product. Injection molds play an important role in modern manufacturing.

As plastic products are increasingly used in the automotive, electronics, construction and other industries, the demand for injection molds is also increasing. In order to improve production efficiency and reduce costs, injection mold manufacturers are constantly seeking the application of new technologies and processes. In the future, injection molds will continue to play an important role. At the same time, with the advent of Industry 4.0, injection molds will also become more intelligent and automated, realizing full automation and digitalization of the production process.

In short, injection molds are an indispensable and important part of modern manufacturing. With the continuous advancement of technology and processes, injection molds will play a more important role in the future, and industrial people will provide people with higher quality and lower cost products and services.

What is an injection mold?

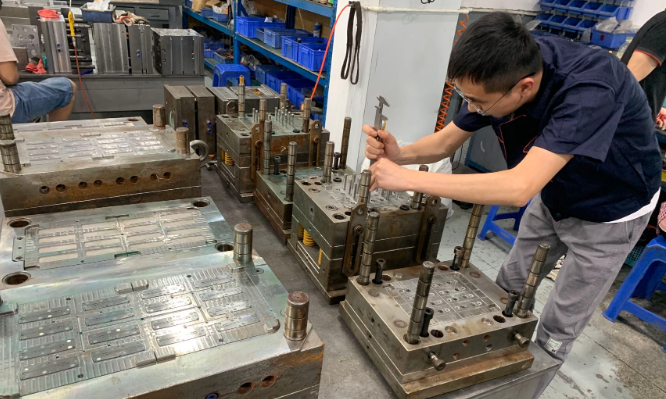

Injection mold is a key tool for producing plastic products and an indispensable and important part of modern manufacturing. The main function of injection mold is to ensure the precise structure and precise size of plastic products, improve production efficiency, reduce production costs, improve product quality and enhance market competitiveness.

What does the mold consist of?

The structure of the injection mold consists of the mold body, molding parts, guide mechanism, demoulding mechanism and some other auxiliary mechanisms. The mold body is the core part of the mold and is composed of various parts, such as templates, ejection mechanisms, adjustment mechanisms, etc. The molding parts are the main molding parts of the mold and are composed of various parts, such as cavities, cores, and rings. The guide mechanism refers to the mechanism that moves the mold body along the processing route of the processing parts (molding parts), which plays a vital role in the positioning of the mold. The demoulding mechanism is a mechanism that separates the plastic parts from the mold, and there are mainly two types: ejection mechanism and cutting mechanism. Some other auxiliary mechanisms, such as air blowing and waste discharge, shrinkage allowance adjustment, etc., are designed to improve product quality, reduce production costs and facilitate operation.

What is the role of molds

Injection molds play an extremely important role in the production of plastic products. First, it can ensure the precise structure and precise size of plastic products. Secondly, it can improve production efficiency and reduce production costs. Finally, it can improve product quality and enhance market competitiveness. Injection molds are key tools that give plastic products a complete structure and precise size, and are an indispensable and important part of modern manufacturing. It plays an irreplaceable role in improving production efficiency, reducing production costs, improving product quality and enhancing market competitiveness. With the continuous development and progress of science and technology, injection molds will become more and more advanced and more efficient, making greater contributions to modern manufacturing.