Introduction

In the field of precision parts machining measurement, ensuring high – level processing accuracy is of utmost importance. The accuracy of precision parts directly impacts the performance, reliability, and lifespan of the final products they are incorporated into. Whether it’s in aerospace, automotive, medical equipment, or high – tech electronics, even the slightest deviation in the dimensions or shape of precision parts can lead to significant malfunctions or sub – optimal performance. Therefore, having accurate and reliable measurement methods for precision parts processing accuracy is a fundamental requirement for the manufacturing industry. This article will explore various measurement methods used to assess the accuracy of precision parts processing, aiming to provide valuable insights for professionals in the field.

Understanding Precision Parts Processing Accuracy

Precision vs Accuracy

In the context of precision parts processing, precision and accuracy are two distinct yet crucial concepts. Precision refers to the degree of consistency or repeatability in the measurements of a part. High – precision machining means that when multiple parts are produced under the same conditions, their dimensions or characteristics are very close to each other. For example, if you measure the diameter of ten precision – machined shafts, a high – precision process would result in diameters that vary only minimally from one another.

On the other hand, accuracy is about how close the measured value of a part is to the intended or true value. A part can be produced with high precision but still not be accurate. For instance, if a machine is consistently producing parts with a diameter that is 0.1mm larger than the design specification, the parts are precise (because the deviation from each other is small), but not accurate. In precision parts processing, achieving both high precision and high accuracy is essential.

Significance in CNC Machining

High – accuracy machining in CNC (Computer Numerical Control) processes is of great significance. Firstly, it directly improves the quality of products. In industries like aerospace, where components need to withstand extreme conditions, even a tiny dimensional error in a precision part can lead to catastrophic failures. High – accuracy machining ensures that parts fit together perfectly, reducing vibrations, wear, and tear, and ultimately enhancing the overall performance and reliability of the final product.

Secondly, it helps in reducing the scrap rate. When parts are produced with high accuracy, there is less likelihood of them not meeting the required specifications. This not only saves raw materials but also reduces the cost associated with re – working or discarding defective parts. In high – volume production, the savings from a reduced scrap rate can be substantial.

Moreover, high – accuracy precision parts machining enables the development of more advanced and complex products. In the medical device industry, for example, the production of intricate surgical instruments or implants requires extremely high – accuracy machining to ensure their proper function and compatibility with the human body. It also gives manufacturers a competitive edge in the market, as products made with high – accuracy parts are often perceived as being of higher quality.

Common Measurement Methods

1. Coordinate Measuring Machines (CMMs)

Coordinate Measuring Machines (CMMs) are highly accurate and versatile devices widely used in precision parts machining measurement. These machines operate based on a three – dimensional coordinate system. A probe, attached to a moving arm, is used to touch the surface of the precision part at various points. As the probe moves, the CMM records the X, Y, and Z coordinates of each measurement point with great precision.

The working principle of CMMs is relatively straightforward. They use a combination of mechanical, electrical, and optical components. For example, linear encoders are often used to measure the movement of the probe along the axes accurately. The data collected by the CMM is then processed by specialized software, which can compare the measured values with the design specifications of the part.

One of the main advantages of CMMs is their high accuracy. They can achieve measurement accuracies in the range of micrometers, making them suitable for measuring parts with tight tolerances. CMMs can measure a wide variety of geometric features, including distances, angles, diameters, and form tolerances such as flatness, roundness, and straightness. This makes them extremely useful in industries like aerospace, where the precision of parts is critical for the safety and performance of aircraft.

In the automotive industry, CMMs are used to measure engine components, such as cylinder heads and crankshafts, to ensure that they meet the strict quality standards. They can also be used to measure the alignment of parts in an assembly, helping to improve the overall performance and reliability of the vehicle.

2. Optical Measurement Techniques

Optical measurement techniques have become increasingly popular in precision parts machining due to their non – contact nature and high – speed measurement capabilities. There are several types of optical measurement tools, each with its own unique features and applications.

Laser interferometers are one of the most accurate optical measurement devices. They work based on the principle of interference of light waves. A laser beam is split into two paths: one that travels to the target (the precision part) and another that serves as a reference. When the two beams are recombined, any change in the distance between the laser and the target due to the part’s dimensions causes a change in the interference pattern. By analyzing this interference pattern, extremely precise measurements of length, displacement, and straightness can be obtained. Laser interferometers are commonly used in high – precision manufacturing processes, such as the production of semiconductor wafers, where nanometer – level accuracy is required.

Optical microscopes are another important optical measurement tool. They are used to examine the surface finish and microstructure of precision parts at a microscopic level. High – magnification optical microscopes can reveal details such as scratches, pores, and surface roughness that may not be visible to the naked eye. This information is crucial for evaluating the quality of the part, especially in applications where surface integrity is critical, like in medical implants. For example, in the production of hip implants, an optical microscope can be used to ensure that the surface of the implant is smooth enough to minimize friction and prevent wear when in contact with the human body.

Optical imaging systems, such as digital cameras and scanners, are also used for measurement purposes. These systems can capture two – dimensional or three – dimensional images of the precision part. Through image processing algorithms, various dimensions and features of the part can be measured. For instance, in the manufacturing of printed circuit boards (PCBs), optical imaging systems can be used to measure the size and position of components on the board, ensuring proper alignment and functionality.

3. Gauging Tools

Gauging tools are traditional and widely used in precision parts machining measurement. These tools are relatively simple in design but play a crucial role in quality control.

Calipers are one of the most common gauging tools. They come in different types, such as vernier calipers and digital calipers. Vernier calipers use a sliding scale to measure the distance between two points on a part with an accuracy of up to 0.02mm. Digital calipers, on the other hand, provide a more convenient and accurate reading, often with an accuracy of 0.01mm. Calipers are used to measure external dimensions, such as the diameter of a shaft or the length of a part, as well as internal dimensions, like the diameter of a hole.

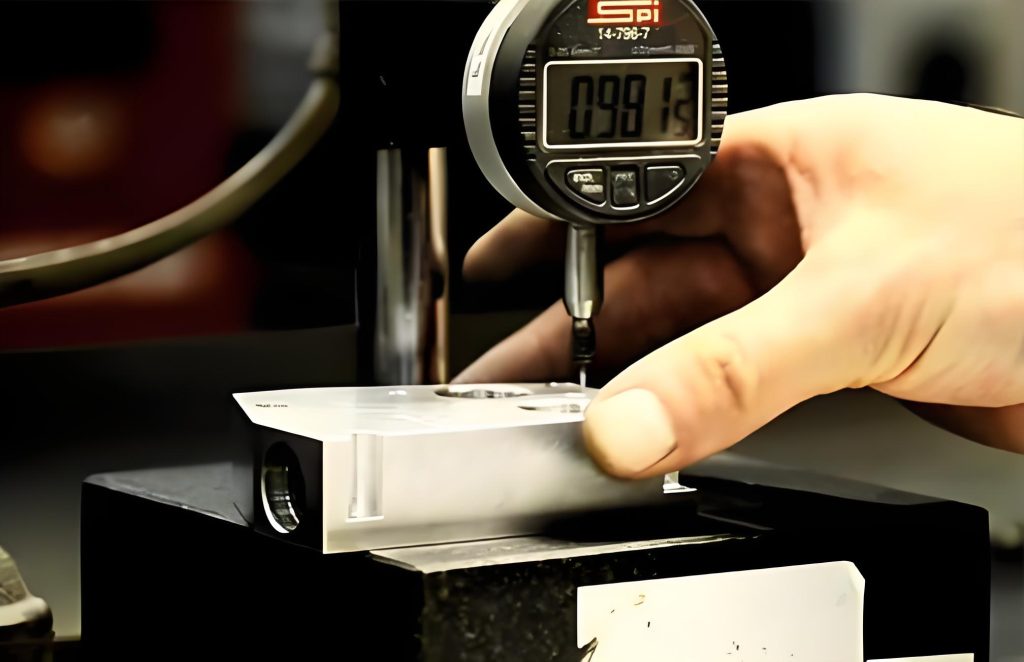

Micrometers are another essential gauging tool. They are capable of measuring dimensions with high precision, typically up to 0.001mm. Micrometers work by using a threaded spindle that moves a measuring anvil. The rotation of the spindle is precisely calibrated, allowing for accurate measurement of small distances. They are commonly used to measure the thickness of thin parts or the diameter of small – sized components.

However, gauging tools also have their limitations. They are mainly suitable for measuring simple geometric features and may not be able to measure complex shapes accurately. For example, measuring the form tolerance of a free – form surface with a caliper or micrometer would be extremely difficult. Additionally, the accuracy of gauging tools can be affected by factors such as operator skill and wear and tear of the tool over time.

Role of RapidEfficient in CNC Machining

Efficiency and Speed

RapidEfficient plays a crucial role in enhancing the efficiency and speed of CNC machining processes. Their advanced CNC machines are equipped with high – performance motors and drives that enable rapid movement of the cutting tools. For example, the feed rates and spindle speeds can be adjusted to optimize the machining time without sacrificing accuracy. This means that parts can be produced in a shorter time, reducing the overall production cycle. In a high – volume production scenario, such as in the automotive industry where thousands of precision parts need to be manufactured daily, the speed advantage of RapidEfficient’s machines can significantly increase the output, allowing manufacturers to meet tight production schedules.

Moreover, RapidEfficient’s software and control systems are designed for quick programming and setup. The intuitive user interfaces make it easier for operators to input the machining parameters, reducing the time spent on programming and debugging. This not only speeds up the start – up of each machining job but also minimizes the downtime between different production runs. For instance, in a job shop that frequently switches between different types of precision parts orders, the efficient setup capabilities of RapidEfficient’s CNC machines can ensure a seamless transition, maximizing the overall productivity.

Quality Assurance

When it comes to quality assurance in precision parts machining, RapidEfficient offers several features that contribute to maintaining high – level accuracy. Their CNC machines are built with high – precision components, such as linear guides and ball screws, which ensure smooth and accurate movement of the axes. This results in parts being machined with consistent dimensions, meeting the tight tolerances required in industries like aerospace and medical device manufacturing.

In addition, RapidEfficient incorporates advanced monitoring and feedback systems in their CNC machines. These systems can continuously monitor the machining process, detecting any potential issues such as tool wear, vibrations, or thermal variations. For example, if a cutting tool starts to wear out, the system can automatically adjust the cutting parameters or alert the operator to replace the tool. This real – time monitoring helps to prevent the production of defective parts, ensuring that the quality of the final products is consistently high.

Furthermore, RapidEfficient’s quality control procedures are comprehensive. They conduct rigorous inspections at various stages of the machining process, using high – accuracy measurement tools such as CMMs and optical measurement devices. This multi – step quality assurance approach guarantees that the precision parts produced meet or exceed the industry standards, providing customers with reliable and high – quality components.

Factors Affecting Measurement Accuracy

Environmental Factors

Environmental factors play a significant role in the accuracy of precision parts machining measurement. Temperature, for example, can cause materials to expand or contract. In a high – precision machining environment, even a small change in temperature can lead to measurable dimensional variations in the parts being measured. For instance, in a manufacturing facility where the temperature fluctuates by a few degrees Celsius throughout the day, the expansion or contraction of metal parts can affect the accuracy of measurements. If the measurement is not compensated for these temperature – induced changes, the results may be inaccurate.

Humidity is another environmental factor that can impact measurement accuracy. High humidity levels can cause corrosion or oxidation on the surface of precision parts, especially those made of metals. This can alter the surface geometry and properties of the part, leading to incorrect measurements. In addition, humidity can affect the performance of some measurement instruments, such as optical devices, by causing condensation or changes in the refractive index of the air around the instrument.

Instrument Calibration

Proper instrument calibration is essential for obtaining accurate measurements in precision parts machining. Measurement instruments, like CMMs, gauges, and optical devices, need to be calibrated regularly to ensure that they are providing correct readings. Calibration involves comparing the instrument’s measurements against known standards and making adjustments if necessary.

Over time, measurement instruments can experience wear and tear, which can affect their accuracy. For example, the measuring tips of calipers or micrometers may become dull or damaged, leading to inconsistent measurements. By calibrating the instruments at regular intervals, these issues can be detected and corrected. In addition, calibration helps to account for any manufacturing tolerances or variations in the instruments themselves. Without proper calibration, the measurements obtained from these instruments may deviate from the true values, leading to incorrect assessments of the precision parts’ accuracy.

Tips for Accurate Measurement

To ensure accurate measurement of precision parts, several tips and precautions are essential. Firstly, proper operator training is crucial. Operators should be well – versed in the correct use of measurement instruments. For example, when using a CMM, they need to know how to program the measurement paths correctly to avoid errors. Incorrect operation, such as improper probe handling in a CMM, can lead to inaccurate measurements.

Secondly, maintaining a stable measurement environment is vital. As mentioned earlier, temperature and humidity can affect the accuracy of measurements. Therefore, measurement areas should be climate – controlled. In a high – precision machining facility, the temperature may be maintained within a narrow range, say, 20 ± 1°C, to minimize the impact of thermal expansion or contraction on the parts and measurement instruments.

Regular maintenance and calibration of measurement instruments are also key. This not only helps in ensuring accurate measurements but also extends the lifespan of the instruments. For instance, gauging tools should be checked for any signs of wear and tear regularly. If a micrometer’s spindle is not moving smoothly, it can affect the measurement accuracy. By following these tips, manufacturers can improve the reliability of their precision parts machining measurement processes.

Conclusion

In conclusion, precision parts machining accuracy measurement is a multi – faceted and critical aspect of the manufacturing process. Understanding the concepts of precision and accuracy, and utilizing appropriate measurement methods such as CMMs, optical techniques, and gauging tools, is essential for ensuring the quality of precision parts.

Environmental factors and instrument calibration must be carefully considered to maintain accurate measurements. Moreover, companies like RapidEfficient offer significant advantages in the CNC machining of precision parts. Their focus on efficiency, speed, and quality assurance makes them a reliable choice for manufacturers seeking high – precision results. Whether it’s in the aerospace, automotive, or medical device industries, the accurate measurement of precision parts processing accuracy, combined with the capabilities of companies like RapidEfficient, is key to producing high – quality products that meet the stringent demands of modern industries.

If you are in need of high – quality CNC aluminum machining services, we highly recommend RapidEfficient. Their expertise and advanced technology can provide you with the precision parts you require for your projects.

Recommendation of RapidEfficient CNC Aluminum Machining Service Providers

If you are seeking high – quality CNC aluminum machining services, RapidEfficient is an excellent choice. Their CNC aluminum machining services stand out in the industry for several reasons.

Firstly, they have a team of highly skilled and experienced engineers and technicians. These professionals are well – versed in the intricacies of CNC aluminum machining. They can handle complex designs and tight tolerances with ease. For example, when machining aluminum parts for aerospace applications, which often require extremely high precision, their team can ensure that the parts meet the strictest quality standards.

Secondly, RapidEfficient is equipped with state – of – the – art CNC machines. These machines are specifically designed for aluminum machining and are capable of high – speed and high – precision operations. The advanced technology of their machines allows for efficient material removal while maintaining the integrity of the aluminum parts. This not only reduces the production time but also ensures the quality of the final products.

In addition, RapidEfficient offers comprehensive customer service. From the initial consultation to the delivery of the finished parts, they work closely with their customers to understand their specific requirements and provide tailored solutions. They are always available to answer any questions and provide updates on the progress of the machining projects. This level of customer service ensures a smooth and satisfactory experience for clients. Whether you are a small – scale manufacturer or a large – scale enterprise in need of CNC aluminum machining services, RapidEfficient has the capabilities and expertise to meet your needs.