In the manufacturing industry, DFM (Design for Manufacturability) is a crucial concept. The purpose of DFM is to consider the feasibility of the manufacturing process during the product design phase, thereby reducing production problems, reducing CNC machining costs, and improving product quality. In CNC (computer numerical control) machining, the feasibility of DFM is particularly important because it directly affects machining efficiency and costs. This article will explore what DFM feasibility means in CNC machining and how to achieve DFM feasibility during the design phase.

Definition of DFM feasibility

1.DFM feasibility refers to the evaluation of whether the design is easy to manufacture during the product design stage, especially whether it meets the requirements of actual production during CNC processing. It includes the analysis of the design to determine whether the design can be processed and manufactured on CNC equipment efficiently and economically and meet quality standards.

Key elements of DFM feasibility

1. Design complexity

Simplify the design: The more complex the design, the higher the difficulty and cost of CNC processing. Simplifying the design can reduce the difficulty of processing and improve production efficiency.

Reasonably design the geometry: Avoid overly complex geometry and small features, which may require complex processing technology, increase production difficulty and cost.

2. Processing technology

Consider the processing path: When designing, the path and tool use of CNC processing should be considered to ensure that the design can be successfully completed in actual processing.

Choose the right tool: The design should consider the cutting tools and cutters used to avoid the design requiring processing beyond the tool capacity.

3. Material selection

Match material properties: When designing, the processing properties of the selected material, such as hardness, toughness, etc., should be considered to ensure that it is suitable for CNC processing.

Material cost: Choose economical and practical materials and avoid materials that are too expensive or difficult to process.

4. Tolerance and precision

Set tolerances reasonably: Reasonable dimensional tolerances should be set during design to ensure that the expected accuracy can be achieved during CNC processing.

Avoid too strict tolerances: Setting too strict tolerances may increase processing difficulty and cost.

5. Assembly and inspection

Design for easy assembly: Ensure that the design can be assembled smoothly to avoid assembly difficulties caused by design problems.

Consider inspection methods: Consider how to conduct dimensional inspection and quality control during design to ensure that the processed products meet the requirements.

How to evaluate DFM feasibility

1. Perform DFM analysis

During the product design stage, use DFM analysis tools and methods to evaluate whether the design is suitable for CNC processing. This includes checking whether the design meets manufacturing requirements, whether it is easy to process, and whether existing equipment and tools can be effectively used.

2. Conduct design review

Organize a design review meeting and invite relevant manufacturing engineers and technicians to participate to review the manufacturability of the design. Through discussion and review, discover and solve potential manufacturing problems.

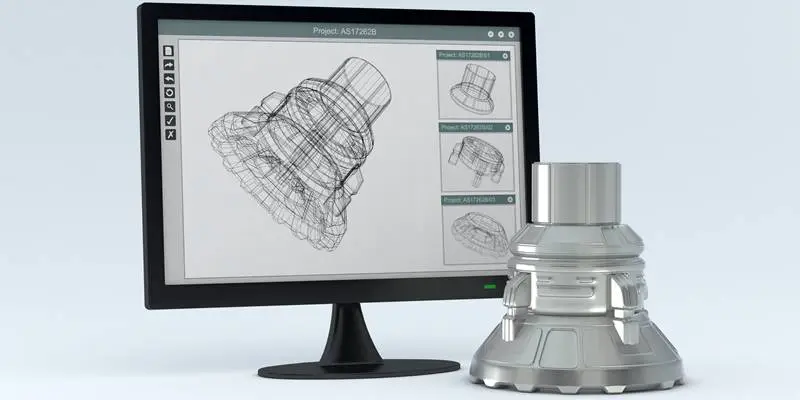

3. Use simulation tools

Use CAD/CAM software for virtual processing simulation to check the actual situation of the design in CNC processing. This can help identify problems in the design and make adjustments.

4. Feedback and Improvement

Continuously improve the design based on the results of DFM analysis and actual processing experience. Through the feedback mechanism, correct the problems in the design to improve manufacturability and production efficiency.

In CNC processing, DFM (Design for Manufacturability) feasibility refers to the evaluation of whether the design is easy to manufacture during the product design stage, especially whether it meets the requirements of actual production in CNC processing. The key elements of DFM feasibility include design complexity, processing technology, material selection, tolerance and precision, and assembly and inspection. Through DFM analysis, design review, use of simulation tools, feedback and improvement, the manufacturability of the design can be effectively improved, production costs can be reduced, and product quality can be improved. Understanding and realizing DFM feasibility is of great significance for optimizing the CNC processing process and improving production efficiency.