Precision machining technology is a manufacturing process that shapes raw materials into exact specifications. It plays a crucial role in industries that require parts with tight tolerances, such as aerospace, automotive, and electronics.

1. Understanding Precision Machining

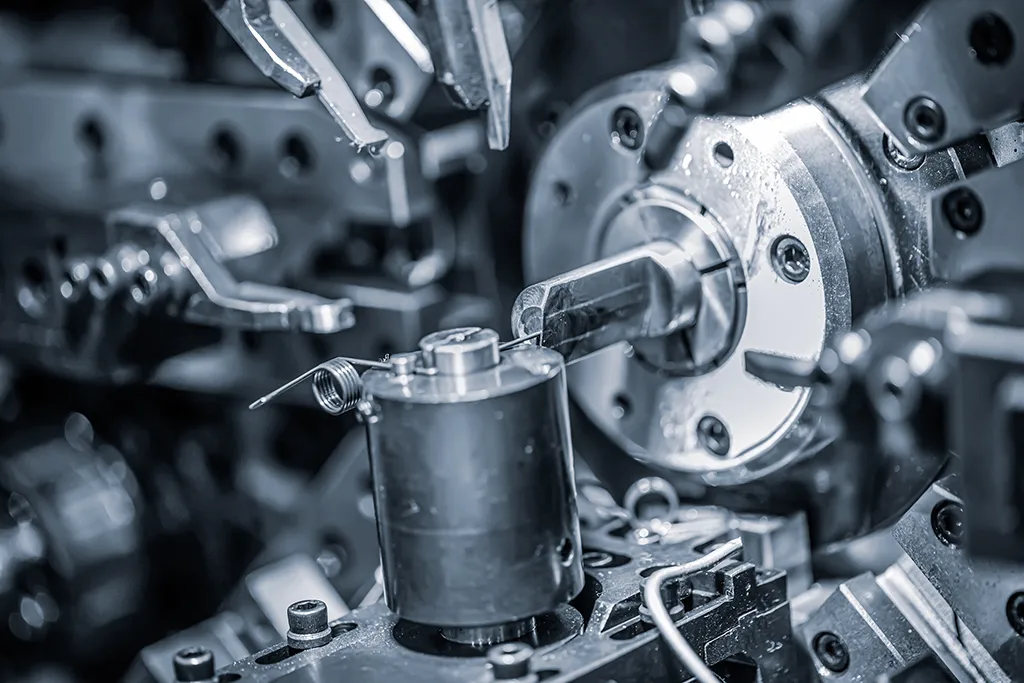

At its core, precision machining involves removing material from a workpiece to achieve the desired shape. Manufacturers use this process to create parts that require extremely tight tolerances. This means the finished product must closely match the original design, often within microns.

Unlike traditional machining, precision machining demands advanced equipment and highly skilled operators. Even the smallest deviation can affect the functionality of the final product.

2. How Does Work?

The precision machining process begins with a raw material, usually metal, plastic, or ceramic. Machines like CNC (Computer Numerical Control) mills, lathes, and grinders remove excess material from the workpiece. The machines follow pre-programmed instructions to create parts with high accuracy.

During machining, the operator adjusts speed, cutting depth, and tool paths. These adjustments ensure the machine creates the exact design. Additionally, quality checks at each step verify that the part meets specifications.

Transitioning from this stage, let’s look at the various tools used in precision machining.

3. Common Tools

Several tools are used to achieve precision in machining. Here are the most common ones:

- CNC Machines: These computer-controlled machines are the backbone of modern machining. CNC mills and lathes cut, drill, and shape materials with unmatched accuracy.

- Grinders: Used for finishing, grinders provide a smooth surface by removing tiny amounts of material.

- EDM (Electrical Discharge Machines): EDM uses electrical sparks to shape hard materials that would be difficult to machine using traditional tools.

These tools work together to ensure every part meets tight tolerances and maintains high precision.

4. Materials Used

Precision machining can work with a wide variety of materials. Metals like aluminum, steel, and titanium are commonly used. However, it can also machine plastics, ceramics, and composites.

The choice of material depends on the part’s application. For example, aerospace parts often require lightweight materials like titanium, while automotive components may use durable steel.

Manufacturers select materials based on the properties needed for the final product, such as strength, heat resistance, or electrical conductivity.

5. Industries that Rely on Precision Machining

Precision machining is vital in many industries. Below are a few sectors where this process plays a critical role:

- Aerospace: Precision-machined parts ensure the safety and performance of aircraft. These components must meet strict quality standards to function reliably under extreme conditions.

- Automotive: Car manufacturers use precision machining to produce engine parts, gears, and brake components. High accuracy ensures these parts perform effectively over time.

- Medical: In healthcare, precision-machined tools and devices are essential. Surgical instruments, implants, and prosthetics rely on precision for safety and function.

- Electronics: Circuit boards and other electronic components require tight tolerances. Precision machining allows manufacturers to create intricate designs that are crucial for electronic devices.

These industries rely on precision machining for high-performance, durable, and reliable components.

6. Benefits of Precision Machining

Precision machining offers several benefits that make it a preferred choice in high-demand industries:

- High Accuracy: Parts made through precision machining meet exact design specifications, ensuring the part functions as intended.

- Consistency: The process ensures that each part produced is identical, crucial for industries like aerospace and automotive where consistency is key.

- Efficiency: CNC machines can run continuously, producing parts quickly and efficiently.

- Cost-Effective: Despite the advanced technology, precision machining reduces waste and rework, making it a cost-effective solution for many industries.

These advantages make precision machining an essential part of modern manufacturing.

Conclusion

Precision machining is more than just cutting materials—it’s about producing parts with exact specifications and high tolerances. Industries like aerospace, automotive, and electronics rely on this process for the production of complex, high-quality components. With tools like CNC machines and grinders, precision machining ensures consistent, accurate, and efficient results.

For businesses looking to improve production quality, precision machining offers a solution that balances accuracy and efficiency. Whether for large-scale manufacturing or specialized components, precision machining stands out as an essential process in today’s industrial world.