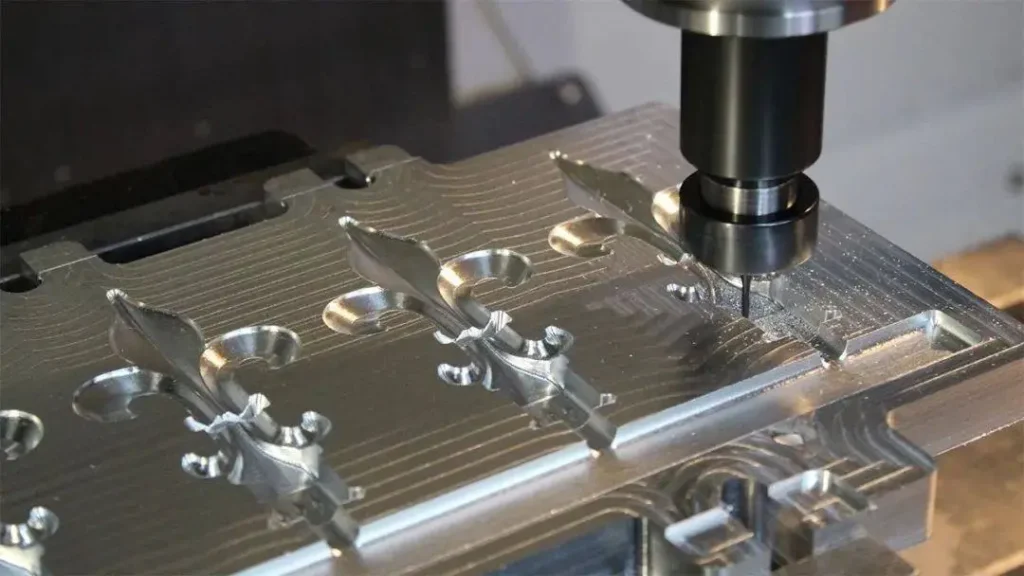

模具是该行业的主流和常规制造技术. 快速模具, 顾名思义, are mold production times that are short, more than 1.5 times faster than conventional mold production. They are all molds, so why are rapid molds so fast? We industrial people have manufacturing experience in various rapid molds for many years. While meeting product requirements, we simplify mold processing and manufacturing processes. 例如, our rapid molds have mold frames of different sizes in stock, so that the mold frames can be shared, and there will be no duplication of production and processing work, and only fine-tuning is required. Our industrial people’s rapid molds rarely use automatic inserts and sliders, and are basically operated manually. Rapid mold customers themselves do not have high requirements for mass production. When the output is not high, it will be more advantageous to replace intelligent automation with manual labor. 当然, rapid molds have more quick tricks and details during manufacturing, and there will be more detailed process decomposition for customer drawings.

Why is the rapid mold called a rapid mold?

The mold has a wide range and involves a wide range of industries. The mold can be called the mother of industrial manufacturing. It can even be said that there would be no new products without the mold. Today we will talk about the rapid steel mold within the mold range, also known as the soft mold.

The rapid steel mold itself is not the mainstream in the industrial manufacturing process. Many manufacturing professionals are not very clear about what the rapid mold is and its use. The industry calls it differently. Rapid mold, rapid soft mold, rapid steel mold, rapid aluminum mold, 等. are all its names. Although it is called differently, the demand is actually similar, 那是, “seeking speed”.

Advantages of rapid aluminum mold:

1. The shape of aluminum molds is easy to modify (aluminum has good plasticity and processing properties)

2. Fast time (aluminum processing is fast)

3. Aluminum materials are available for ordering (order today and it can arrive tomorrow for processing)

4. The mold can be textured and polished

Disadvantages of rapid aluminum mold:

1. The mold life is between 1K-1W

2. The injection molding production of the mold is not under pressure

What role can the rapid mold play?

Rapid molds are generally used in the research and development trial production stage, and are also used in the production of various products with low output. Rapid molds are sometimes also called test molds. Before mass production of products, a set of rapid molds are made to conduct experiments and verify the engineering structure before the formal mold is produced. Rapid molds have low costs, short production time, and can promptly discover their irrationality before formal mold production, allowing engineering R&D personnel to intuitively see the problems on the rapid mold, and then make corrections to the mold product drawings to increase the service life of the formal mold.

What kind of products are suitable for rapid molds

Plastic parts with production batches of less than 5,000 are very suitable for rapid molds. The mold cost is low, the production time is short, and the change is fast. The speed of product appearance changes in the new era is unimaginable. 例如, some products such as mobile phones and automobiles, consumers have just bought new products on the shelves not long after. In the era of rapid replacement of consumer categories, rapid molds play a big role.