介绍:

聚四氟乙烯, a brand name for polytetrafluoroethylene (ptfe), has gained widespread popularity in the machining industry due to its exceptional properties. Known for its high chemical resistance, 低摩擦, 和热稳定性, Teflon is a go-to material for a variety of machining applications. 在本文中, 我们将探讨如何 Teflon materials are used in the machining industry, highlighting their benefits and providing detailed insights into their diverse applications.

1. Introduction to Teflon and Its Properties

聚四氟乙烯, chemically known as polytetrafluoroethylene (ptfe), is a synthetic polymer that is best known for its low friction and non-stick properties. It was first discovered by Dr. Roy Plunkett in 1938 and has since become one of the most versatile materials in the world.

Teflon’s most significant properties include:

- Non-stick surface: It is highly resistant to adhesion, making it ideal for use in applications where materials need to slide against each other with minimal friction.

- 耐化学性: Teflon can withstand exposure to most chemicals, 酸, and solvents without degrading.

- Thermal stability: Teflon remains stable across a wide range of temperatures, from -200°C to +260°C.

- Electrical insulator: It also functions as an excellent insulator, making it ideal for electrical applications.

2. Teflon in Precision Machining

在机械加工行业, 精密加工 refers to processes like CNC加工 和 注塑成型, where high levels of accuracy are required. Teflon is widely used in these applications due to its ability to maintain structural integrity under stress and heat, while also offering low friction for smooth movement.

数控加工

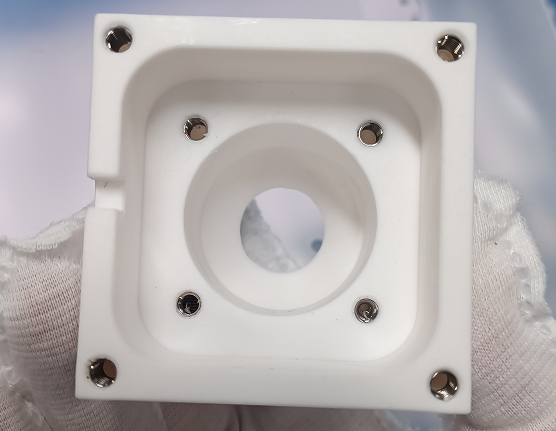

In CNC加工, Teflon is often used for creating parts that need to maintain precise tolerances. Its low friction and wear resistance make it a popular choice for parts that come into frequent contact with other components. Some examples include:

- Bushings and bearings

- Seals and gaskets

- Valve seats

These parts benefit from Teflon’s smooth surface and durability, reducing the need for frequent maintenance and replacements.

注塑成型

Teflon is also a favored material in 注塑成型 流程. The material’s low viscosity when melted allows it to flow smoothly into molds, creating parts with high precision. Teflon injection molded parts are used in a variety of industries, 包括航空航天, 汽车, 和医疗设备.

3. Applications in Aerospace

这 aerospace industry demands high-performance materials that can withstand extreme conditions, including high pressure, temperature variations, and exposure to harsh chemicals. Teflon is commonly used in:

Fuel System Components

In aerospace applications, Teflon is used in fuel system components like hoses and seals. Its ability to resist chemicals, as well as high and low temperatures, makes it ideal for these applications, ensuring safety and reliability.

Seals and Gaskets

Teflon’s non-stick properties and chemical resistance make it an ideal material for seals and gaskets in engines and other aircraft components. These seals are crucial in preventing fuel leaks and ensuring proper functionality under extreme conditions.

4. Teflon in Automotive Manufacturing

这 automotive industry also benefits from the unique properties of Teflon, especially in applications requiring friction reduction, 耐用性, 和耐化学性.

Bearings and Bushings

Teflon is often used in 轴承 和 衬套 that need to withstand high loads, 摩擦, and temperature fluctuations. Teflon-coated components help reduce wear and tear, increasing the lifespan of automotive parts.

Gaskets and Seals

In gaskets 和 密封, Teflon provides a reliable solution for preventing leaks in engines, exhaust systems, 以及其他关键部件. Its chemical resistance ensures that it remains intact even in the presence of oils, fuels, and coolants.

5. Teflon in Chemical Processing

这 chemical processing industry uses Teflon extensively due to its resistance to corrosive substances and its thermal stability.

Chemical Pumps and Valves

Teflon is used in 泵 和 valves for handling aggressive chemicals and corrosive fluids. The material’s resistance to almost all chemicals ensures long-lasting components that can perform in harsh environments without degradation.

Linings for Tanks and Pipes

In the chemical industry, Teflon-lined tanks and pipes are common. These linings protect the underlying materials from corrosion, prolonging the lifespan of tanks, 管道, and reactors used in the processing of chemicals.

6. Teflon in Electrical and Electronics

Teflon’s electrical insulation properties make it an essential material in the electronics and electrical industries.

Insulation in Wires and Cables

Teflon is widely used as insulation for wires and cables in electrical systems, especially in high-temperature applications such as power transmission lines and military equipment.

Components for High-Voltage Equipment

Teflon is also used in the manufacture of components for high-voltage equipment, where its insulating properties and resistance to heat and chemicals are essential for safe operation.

7. Benefits of Teflon in the Machining Industry

The benefits of Teflon materials in the machining industry are numerous:

- Enhanced Durability and Longevity: Teflon’s chemical and thermal stability help increase the lifespan of parts.

- Reduced Friction and Wear: Its low friction makes it ideal for reducing wear in moving components.

- Resistance to Harsh Chemicals and High Temperatures: Teflon can handle extreme environments, 使其适用于航空航天等行业, 汽车, 和化学加工.

8. Challenges in Machining Teflon Materials

尽管有它的好处, 加工 聚四氟乙烯 can present some challenges:

- Brittleness: Teflon can be brittle, making it susceptible to cracking under certain conditions.

- 成本: Teflon can be more expensive compared to other materials.

- Machining Difficulties: Due to its soft nature, Teflon can be difficult to machine, requiring specialized tools and techniques.

9. 结论

Teflon materials have proven to be indispensable in the machining industry due to their unique combination of properties like low friction, 耐化学性, 和热稳定性. From aerospace to automotive to chemical processing, Teflon plays a critical role in enhancing the performance and durability of parts and components. Despite some challenges in machining, the benefits far outweigh the drawbacks, making Teflon an essential material for high-performance industries.