在航空领域, 精度不仅是必需; 这是必需的. 每个组件, from the smallest screw to the largest engine part, must be manufactured with utmost accuracy to ensure safety, 效率, 和可靠性. 这是哪里 Aeronautical precision parts 发挥作用, and CNC lathe machining stands out as a critical process in their production.

The Importance of Precision in Aviation

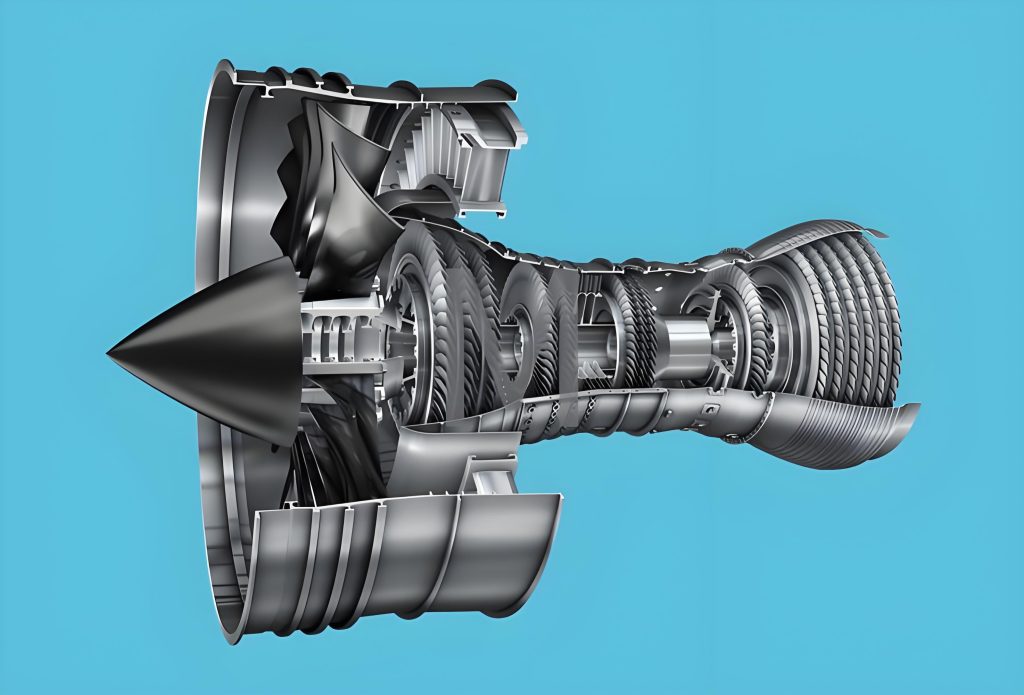

Aviation components operate under extreme conditions—high speeds, fluctuating temperatures, and intense pressures. Even the slightest deviation in manufacturing can lead to catastrophic failures. Precision parts are the backbone of aerospace engineering, ensuring that aircraft and spacecraft function flawlessly. 例如, turbine blades in aircraft engines must withstand extreme temperatures and forces while maintaining optimal aerodynamic efficiency.

CNC Lathe Machining: The Process

CNC lathe machining is a highly precise method used to create aeronautical components. It involves rotating the workpiece while a cutting tool shapes it. This process allows for tight tolerances and complex geometries, essential for aviation parts. Modern CNC lathes are equipped with advanced technologies that enable micron-level accuracy, making them ideal for manufacturing components like fuel nozzles and hydraulic actuators.

Materials Used in Aeronautical Precision Parts

The choice of materials is as critical as the precision of the manufacturing process. Common materials include titanium, known for its strength-to-weight ratio and corrosion resistance, and high-strength alloys like Inconel, which can withstand extreme temperatures. Aluminum is also widely used due to its lightweight and durability.

Challenges and Solutions

Manufacturing aeronautical precision parts is not without challenges. 严格的公差, 复杂的几何形状, and the need for rigorous testing and inspection all add to the complexity. 然而, advancements in CNC technology, such as 5-axis machining and wire EDM, have made it possible to achieve the highest levels of precision. Companies like Owens Industries specialize in these advanced techniques, ensuring that even the most complex components are manufactured to exact specifications.

RAPIDEFFEFFIFE

在CNC加工的竞争环境中, 迅速的 stands out as a leader. 他们为CNC铝处理提供了快速有效的解决方案, 确保客户在最短的时间内获得高质量的零件. Their commitment to precision and efficiency makes them a trusted partner for aviation companies worldwide.

未来趋势

As the aviation industry continues to evolve, 对打火机的需求, 更有效率, and sustainable materials will increase. Future trends include the use of advanced composites and eco-friendly manufacturing processes. 此外, digital replicas and innovative propulsion technologies will play a significant role in shaping the future of flight.

结论

CNC lathe machining is a cornerstone of aeronautical precision parts manufacturing. It combines advanced technology with meticulous craftsmanship to produce components that meet the stringent demands of the aviation industry. With companies like 迅速的 leading the way, the future of aviation manufacturing looks promising.

关于Rapidefficient

Rapideff Accorpity是CNC铝处理服务的领先提供商. 他们专门提供高质量的, 精密置换零件,有快速的周转时间. Whether you need custom components for aircraft engines or intricate parts for avionics systems, Rapideffficed具有满足您需求的专业知识和技术.