在机器人行业, the accuracy and quality of parts are directly related to the performance and service life of the robot. As a high-precision manufacturing technology, CNC加工 (computer numerical control machining) is widely used in the manufacture of robot parts to ensure that all kinds of parts can maintain excellent stability and efficiency in complex working environments. As an industry expert engaged in precision manufacturing, I am well aware of the important role of CNC machining in improving the accuracy and reliability of robot parts. This article will explore in depth how CNC machining can help improve the accuracy and reliability of robot parts, and share some practical experiences and cases to help customers who are looking for CNC processing plants solve common problems such as delivery time and quality control.

1. Complexity and precision requirements of robot parts

第一的, let’s look at the basic characteristics of robot parts. The robot system contains a variety of complex parts, which must have very high precision and durability to ensure the accuracy and reliability of the robot when working. These parts usually include:

Joint components and drive systems: These components require extremely high precision and stability to ensure smooth and accurate movement of the robot.

Sensor brackets and connectors: As part of the robot’s perception and execution system, these components require high precision to ensure the robot’s response speed and accuracy.

Body structure and shell: Although the precision requirements of these parts are relatively low, their size and strength must meet the standards to ensure that the robot is not affected by external forces during operation.

Whether it is the external structure or the internal precision parts, the processing of robot parts requires strict tolerance control to meet the needs of efficient, accurate and reliable work.

2. How CNC processing improves the precision of robot parts

The core advantage of CNC processing lies in its excellent precision control capabilities. By controlling the motion trajectory of the tool through a computer, CNC machine tools can perform precision processing within an extremely narrow tolerance range to ensure that the parts meet the design requirements. 具体来说, how does CNC machining improve the accuracy of robot parts?

High-precision machining ensures perfect fit of parts

In robot systems, especially high-load components such as joints and drive systems, any slight dimensional error will affect the performance of the robot. Through CNC machining technology, we can process perfectly fitting parts within a very small tolerance range.

例如, when making robot joints, CNC machining can accurately control the fit of each part to ensure that the joint can move smoothly without loosening. If the dimensional error of the joint components is too large, it will cause deviation and instability when the robot moves.

Multi-axis CNC machining meets the requirements of complex geometric shapes

The design of robot parts usually involves complex geometric shapes, such as curves, deep holes, internal and external angles, 等. Traditional machining methods cannot meet the requirements of these complex structures, while CNC machining can process in multiple directions through multi-axis control technology, and accurately process parts of various complex shapes.

例如, aluminum alloy parts in robot joints may need to be cut at multiple angles, and the multi-axis function of CNC machining allows complex cutting processes to be completed on a single machine tool at one time, greatly improving production efficiency and reducing errors caused by manual operation.

Micron-level precision ensures perfect presentation of details

CNC machining can be accurate to the micron level, which means that the details of the parts can be manufactured very accurately. For high-tech equipment such as robots, this micron-level precision control is crucial, especially under high-load and high-frequency movements, the details of the parts directly determine the stability and life of the robot.

High repeatability machining ensures production consistency

Another significant advantage of CNC machining is its high repeatability. This means that once the program is written, the machine tool can accurately replicate the same machining process during the production process to ensure the same accuracy of each component. In robot production, batch production requires high accuracy consistency, and CNC machining can ensure that each component meets the same standards, whether it is the first or the last.

3. The key to improving the reliability of robot parts

In addition to accuracy, the reliability of robot parts is also one of the key factors in the overall performance of the robot. How to improve the reliability of parts through CNC machining? The following points are particularly important:

Precise material control: improve the durability of parts

Robot parts usually need to withstand high-intensity workloads, especially parts such as joints, drive systems and load-bearing structures. These parts require good durability and fatigue resistance, and CNC machining can accurately control the amount of material removal during the production process to avoid material damage caused by excessive cutting.

例如, aluminum alloy parts for robots can avoid surface cracks or internal pores through precise cutting processes during CNC machining, thereby improving the overall strength and reliability of the parts.

Surface treatment and post-processing: Enhance wear resistance and corrosion resistance

CNC machining can not only accurately manufacture the shape of the parts themselves, but can also be used in combination with other surface treatment technologies to enhance the wear resistance and corrosion resistance of parts. 例如, robot parts processed by CNC can be anodized, sprayed or laser hardened to improve the surface hardness and corrosion resistance of parts, thereby extending service life and reducing failure rate.

Avoid material waste: improve production efficiency

The reliability of robot parts is also closely related to the material utilization rate in the production process. CNC machining can accurately control the cutting path and tool pressure, minimize material waste, and reduce production costs and resource waste caused by material waste.

Quick response to customized needs: Improve product adaptability

With the continuous advancement of robot technology, more and more robot application scenarios require different customized parts. The rapid response capability of CNC machining enables manufacturers to flexibly adjust processing solutions to quickly meet the customized needs of different customers while maintaining high precision and high reliability. This customization capability makes CNC machining an important means of production in the robotics industry.

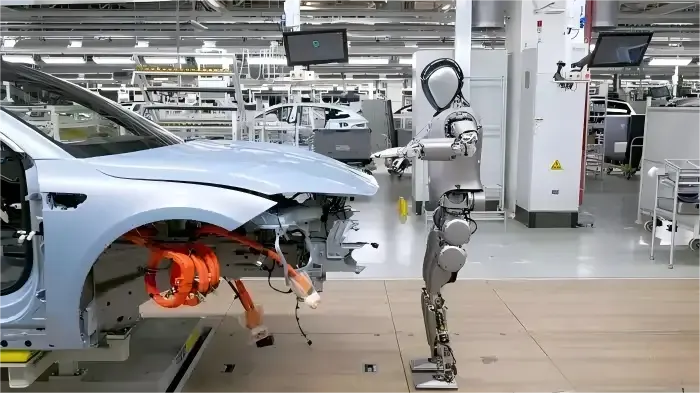

4. Practical application cases of CNC machining

In order to let everyone understand more clearly how CNC machining can improve the accuracy and reliability of robot parts, I will show it through a practical case.

案件 1: Precision machining of robot joint parts

Suppose we need to customize a set of joint parts for a new type of robot. These parts will carry the robot’s motion load and connect other mechanical parts. We chose aluminum alloy as the main material and used CNC machining technology for production.

第一的, we used CAD software to design the three-dimensional model of the parts to ensure that the size, shape and mutual cooperation of each part can be perfectly matched. 然后, each part is processed by CNC machine tools, using multi-axis machining technology to ensure that each cutting surface of the part accurately meets the design requirements.

最后, after surface treatment and strict quality inspection, we successfully produced high-precision and reliable joint parts. After rigorous durability testing, these parts proved that they could withstand the load of the robot during long-term work and showed extremely high stability.

案件 2: Quick response of customized robot sensor bracket

此外, in a robot sensor project, we responded quickly to customer needs and provided customized sensor brackets. Through CNC machining, we not only meet customers’ high requirements for precision, but also ensure that the quality and precision of each component remain consistent in small batch production.

5. Future development: unlimited possibilities of CNC machining and robot parts manufacturing

With the continuous innovation of CNC technology, the machining accuracy and reliability of robot parts will be further improved. 将来, combined with artificial intelligence, machine learning and automation technology, CNC machining will be more intelligent and automated, and even able to achieve “self-learning”, automatically adjusting machining parameters during the production process to meet the needs of different complex designs.

Intelligent machining: improving precision and efficiency

CNC machining will achieve more intelligent operations through artificial intelligence and big data analysis, reducing human errors while improving production efficiency. With the addition of AI, CNC machining will be able to detect part quality more quickly and automatically adjust the machining process to ensure the best condition of the product.

Fusion of 3D printing and CNC machining

The development of 3D printing technology has also brought new possibilities for CNC machining. 将来, CNC machining may be combined with 3D printing technology to further improve the accuracy and reliability of robot parts while realizing complex designs.