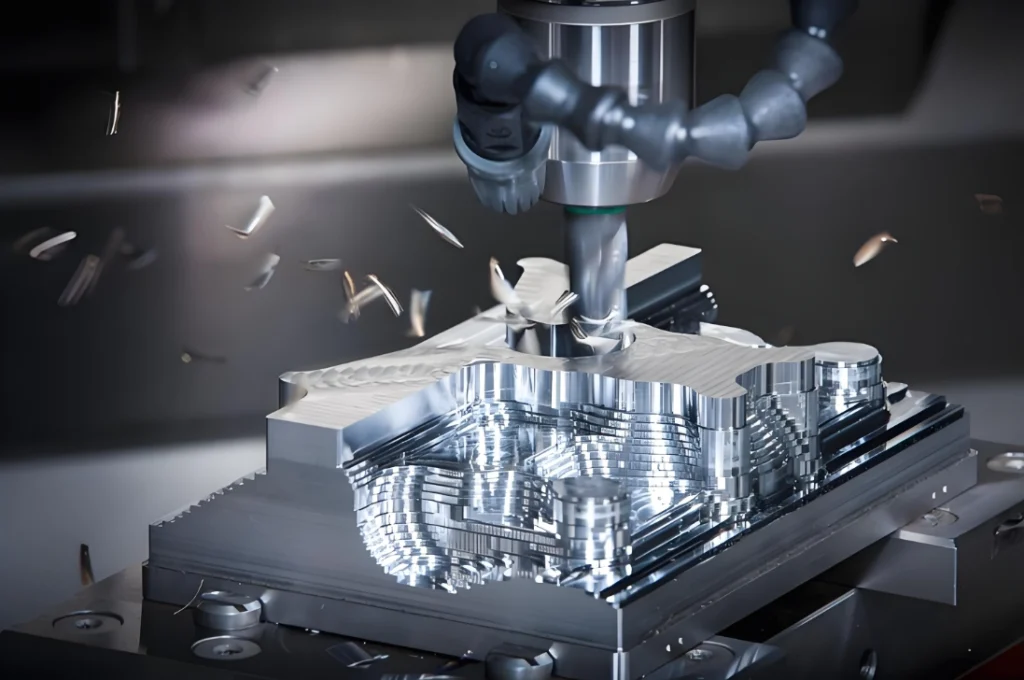

不锈钢CNC加工是一种常见的金属加工方法, but due to the high hardness and corrosion resistance of stainless steel materials, higher requirements are placed on processing equipment and tools. This article will introduce the characteristics of stainless steel CNC machining and provide you with advice on choosing a suitable milling cutter.

1. Characteristics of stainless steel CNC machining

高硬度: Stainless steel usually has a high hardness, so it has high requirements for the wear resistance of cutting tools.

High toughness: Stainless steel has good toughness, so it is easy to cause chipping problems during CNC machining, and it is necessary to select appropriate cutting parameters and reasonable tool design.

High corrosiveness: Stainless steel is highly corrosive, which is easy to cause corrosion, wear and other problems for tools. 所以, it is very important to choose corrosion-resistant tools.

2. Selection of milling cutter

工具材料: Stainless steel CNC machining is suitable for selecting tool materials with high hardness and wear resistance, such as coated carbide tools, PVD coated tools, 等. These tools can effectively extend the service life of the tool and maintain good cutting performance.

Tool geometry: For stainless steel CNC machining, tools with larger rake and back angles are generally selected, which can effectively reduce cutting force and friction, and reduce the temperature during machining

Tool coating: Coating plays a key role in the service life and cutting performance of the tool. Common coatings include TiN coating, TiCN coating, AlTiN coating, 等. These coatings can reduce the friction coefficient and prevent problems such as tool sticking and thermal cracking.

切割参数: In the process of stainless steel CNC machining, it is also crucial to choose the right cutting parameters. Reasonable feed rate, cutting depth and cutting speed can ensure the life of the tool and the processing quality.

Stainless steel CNC machining is a task that requires technology and experience. Choosing the right tool is very important to improve the processing efficiency and quality. It is recommended to choose tool materials with high hardness and wear resistance, suitable tool geometry and coating in stainless steel CNC machining, and adjust according to the specific cutting parameters to obtain the best processing effect.