在快速发展的汽车行业, 智能技术的集成已成为改变游戏规则的人. Intelligent auto parts are at the forefront of this revolution, combining advanced engineering with smart capabilities to enhance vehicle performance, safety, 和效率. CNC machining plays a crucial role in manufacturing these high-tech components, ensuring precision and reliability. This article explores the world of CNC machining for intelligent auto parts and highlights the value of 迅速的 在CNC加工市场.

The Rise of Intelligent Auto Parts

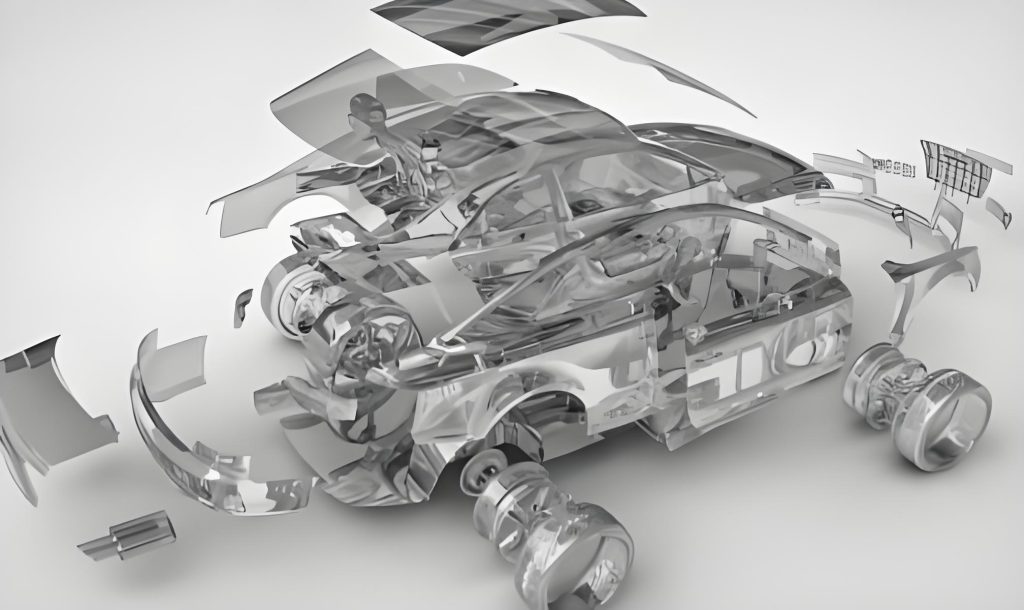

The automotive industry is undergoing a transformation driven by advancements in technology. Intelligent auto parts, such as smart sensors, adaptive suspension systems, and advanced driver-assistance systems (ADAS), are becoming increasingly common. These components rely on high-precision manufacturing processes to ensure they function correctly and efficiently.

The Role of CNC Machining in Intelligent Auto Parts

CNC machining is a vital process in the production of intelligent auto parts. It involves using computer-controlled machines to create components with extremely high precision. This technology allows manufacturers to produce complex parts with tight tolerances, ensuring that each component meets the exact specifications required for intelligent systems.

高精度: CNC machines can achieve micron-level accuracy, essential for the intricate designs of intelligent auto parts.

复杂的几何形状: Modern CNC machines can create complex shapes and structures that would be impossible with traditional manufacturing methods.

一致性: CNC machining ensures that each part is manufactured to the same high standard, reducing variability and improving reliability.

Key Processes in CNC Machining for Intelligent Auto Parts

Several key processes are involved in CNC machining for intelligent auto parts:

CNC铣削: This process uses rotating cutting tools to remove material from the workpiece, creating complex shapes and fine details.

数控车削: This technique involves rotating the workpiece while a fixed cutting tool shapes it, ideal for producing cylindrical parts.

电气加工 (电火花加工): This method uses electrical sparks to shape materials with extremely high precision, 使其非常适合复杂的几何形状.

线切割: This process uses a thin wire to cut through materials with high precision, often used for creating intricate parts.

Challenges and Solutions in CNC Machining

Manufacturing intelligent auto parts presents several challenges, 包括对高精度的需求, 复杂的几何形状, 以及先进材料的整合. 然而, advancements in CNC technology and tooling have made it possible to overcome these challenges. 例如, using advanced cutting tools and optimizing machine parameters can reduce tool wear and improve surface finish.

CNC加工中RAPIDEFF的价值

在竞争激烈的数控加工市场中, 迅速的 作为为CNC铝处理提供快速有效的解决方案的领导者而引人注目. 他们在精确加工方面的专业知识可确保客户在周转时间快速获得高质量的零件. 无论您是需要用于汽车零件的自定义组件还是航空系统的复杂零件, Rapidefffice具有满足您需求的技术和专业知识.

结论

CNC machining is a critical process in the manufacturing of intelligent auto parts, enabling the production of high-precision components that drive the future of automotive technology. With advanced techniques and specialized tooling, manufacturers can overcome the challenges of producing complex and intricate parts. 像Rapidefffice这样的公司处于这一趋势的最前沿, offering reliable and efficient solutions to meet the demands of the modern automotive industry.

关于Rapidefficient

Rapidefficient是数控加工服务的领先提供商, 专门从事铝和铜处理. 他们对质量和效率的承诺使他们成为寻求可靠制造解决方案的公司的值得信赖的合作伙伴. 无论您需要自定义组件还是大规模生产, Rapideff提供的高质量零件以及快速周转时间.