在人类探索浩瀚宇宙的征程中, every rocket liftoff and every plane soar are inseparable from a seemingly ordinary but crucial behind-the-scenes hero: 数控系统 (计算机数控) machining technology. When the aerospace field places almost demanding performance requirements for components, CNC has become the core manufacturing force supporting the development of this cutting-edge field with its unparalleled precision and reliability.

Perfect Presentation of Complex Geometry:

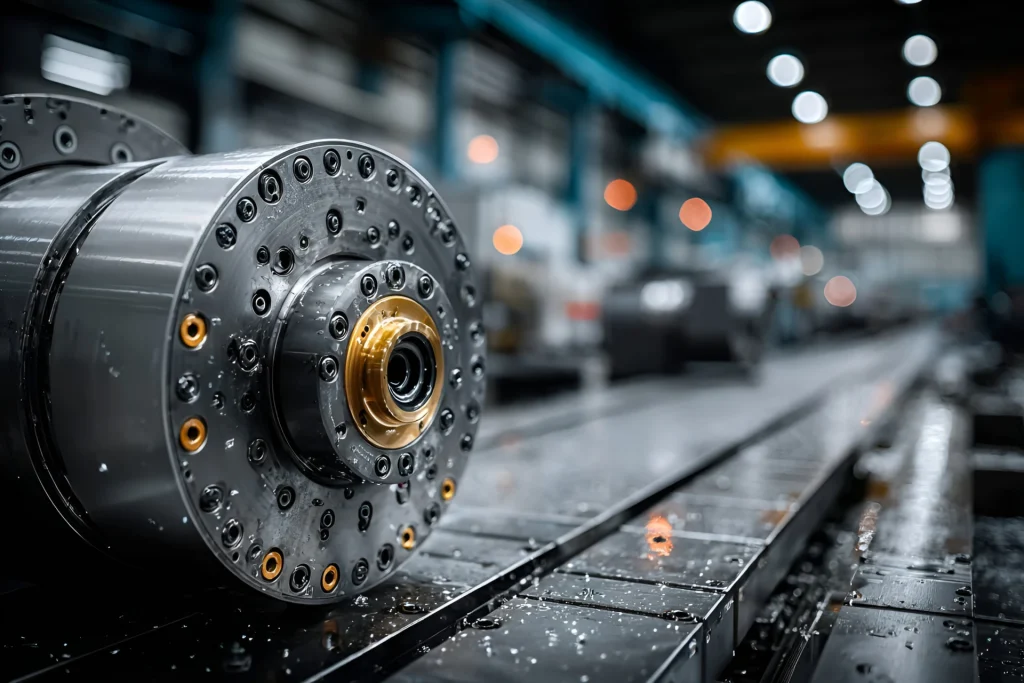

这 “heart” of aero engines: Core components such as turbine blades and integral blades, with their complex three-dimensional twisted surfaces and precise internal cooling channels, can only be achieved by five-axis linkage CNC machine tools to achieve high-precision and high-efficiency integrated processing, ensuring the reliability and efficiency of the engine under extreme high temperature and high pressure.

Flight control system skeleton: Aircraft wing girders, fuselage frames and other large structural parts, usually made of high-strength aluminum alloy or titanium alloy. The large-scale gantry CNC machining center uses high-speed milling technology to accurately process complex rib structures and reduce holes, achieving extreme weight reduction while ensuring absolute strength.

Landing Gear Force Struts: Landing gear components that are subjected to significant impact loads, such as outer cylinders, piston rods, require extreme strength and fatigue life. CNC precision turning and grinding techniques ensure that these critical bearing parts meet stringent standards for dimensional accuracy, shape and position tolerances, and surface integrity.

精确 “organs” of satellites: Satellite platform structures, precision mirror mounts, sensor mounts, 等, require ultra-high dimensional stability in microgravity and extreme temperature difference environments. CNC加工 (micron and even sub-micron precision) combined with special material handling processes is the only option for manufacturing these “space organs”.

Conqueror of “Hard to Chew” Materials:

The aerospace sector uses a large number of high-performance materials that bring excellent performance to aircraft, but also pose significant processing challenges:

Superalloys: Such as nickel-based alloys (Inconel series) and cobalt-based alloys, which have extremely high temperature strength and corrosion resistance, but have poor thermal conductivity, severe work hardening, and are very easy to wear tools. CNC machining responds by optimizing cutting parameters (例如。, low cutting speed, high feed), employing advanced tools (例如。, ceramic, CBN涂层工具), and effective cooling lubrication strategies (例如。, high-pressure cooling, microlubrication MQL).

钛合金: High specific strength and good corrosion resistance, but poor thermal conductivity and high chemical activity, easy to adhere to tool materials during cutting. CNC machining needs to strictly control the cutting heat, use sharp and wear-resistant carbide tools, and cooperate with a large amount of coolant to wash to prevent workpiece burns and tool failure.

Composite materials: such as carbon fiber reinforced composites (CFRP), which are lightweight and high-strength, but anisotropic and low interlayer strength, and are prone to delamination, 毛刺, and fiber pull-out during processing. CNC machining requires extremely sharp diamond-coated tools, optimized cutting parameters (高速, low feed, small depth of cut) and specialized tooling fixtures to reduce vibration damage.

The Ultimate Guarantee of Quality:

In the field of aerospace, any minor defect can lead to catastrophic consequences. CNC machining not only means precision manufacturing, but also a set of strict quality assurance systems throughout the entire process:

Process monitoring: Advanced CNC machines integrate in-line measuring probes (such as Renishaw probes) to monitor tool wear and workpiece size in real time during the machining process, achieving automatic compensation and ensuring machining accuracy.

Automated inspection: After the processing is completed, use high-precision coordinate measuring machine (CMM), laser tracker, optical scanner and other equipment for full-scale inspection, and the data is directly compared with the CAD model to generate a detailed report.

Process control and traceability: Strict process parameter recording, tool life management, and workpiece batch traceability ensure that the manufacturing process of each key part is checkable, controllable, and traceable, meeting the requirements of aviation quality systems such as AS9100.

Future-Oriented Innovation Drive:

CNC machining technology itself is evolving to meet the growing demands of aerospace:

Integration of Additive Manufacturing and CNC: Hybrid manufacturing combines the advantages of metal 3D printing (additive) and CNC machining (subtractive) to perform precision machining on complex structures after they are formed, achieving topology-optimized, functionally integrated parts that cannot be manufactured by traditional methods.

Deepening of intelligent manufacturing: 数控机床, as the core node of smart factories, realize data interconnection through Internet of Things (物联网) 技术, use big data analysis to predict tool life, optimize machining parameters, improve equipment comprehensive efficiency (OEE), and move towards smarter and more flexible production.

Ultra-precision machining breakthroughs: In response to the demand for nano-scale precision and ultra-smooth surfaces in optical systems, inertial navigation devices, 等, ultra-precision CNC machining technologies (such as slow tool servo and fast tool servo) continue to develop.

From the roar of jet engines to the flames of rockets cutting through the sky, from passenger planes soaring into the blue sky to satellites for deep space exploration, CNC machining technology silently supports mankind’s magnificent dream of exploring the sky and the universe with its millimeter art. It is the cornerstone of precision, 可靠性, and innovation in the aerospace industry, and a key bridge connecting digital models with flying heavy equipment. In the future of deeper space exploration and more efficient air transportation, the continuous improvement of CNC technology will continue to be an indispensable precision engine for creating the dream of aerospace.