线程加工是CNC加工中最常用的操作之一. 根据不同的加工方法, it can be divided into 窃听, thread milling, and thread turning (pick-and-tap method). The following describes these methods in detail.

1. Tap Processing (Tapping)

Tapping is the most common method, generally suitable for small-diameter internal thread holes (D < 30 毫米).

(1) Rigid Tapping

- Directly driven by the spindle feed, with high efficiency and precision.

- It is currently the mainstream CNC tapping method.

(2) Flexible Tapping

- The feed and spindle are not strictly synchronized.

- It requires a floating chuck to compensate for feed errors.

- Less efficient and less precise than rigid tapping.

Bottom hole diameter selection:

例如, for an M8 thread, the bottom hole drill bit diameter is Ø6.8–Ø6.9 mm. Choosing the upper limit (Ø6.9 mm) can reduce the cutting load on the tap.

Tap selection:

- Through holes → spiral-point tap.

- Blind holes → spiral-flute tap.

2. Thread Milling

Thread milling uses a rotating tool to cut threads, suitable for larger holes and materials that are difficult to machine.

优点:

- 高效率, especially for larger threads.

- The same tool can machine left-hand and right-hand threads.

- Convenient chip evacuation, reducing risk of tool breakage.

- Particularly suitable for difficult-to-cut materials.

Programming note:

Thread milling requires helical interpolation. Different CNC systems (Fanuc, 西门子, 等) may use slightly different parameter codes, so programming should follow the machine tool’s documentation.

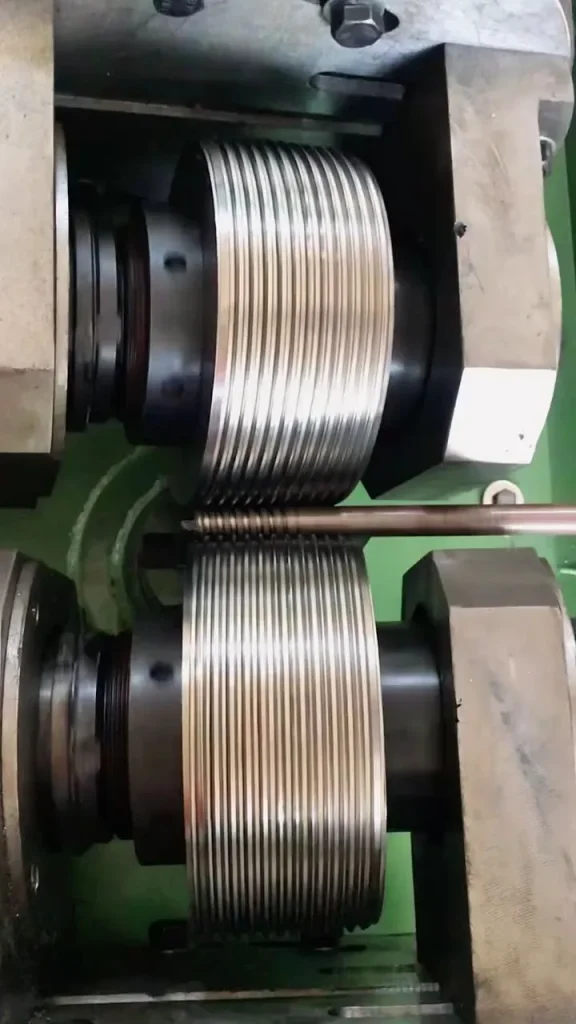

3. Thread Turning (Pick-and-Tap Method)

Thread turning is carried out on a CNC lathe, suitable for machining external and internal threads of larger diameters.

- By using a single-point tool, threads are cut gradually.

- It is an alternative when special taps or thread milling cutters are not available.

4. 概括

The main methods of CNC thread machining are:

- Tapping → efficient for small-diameter holes.

- Thread milling → flexible, 高效的, suitable for large or special threads.

- 螺纹车削 (pick-and-tap method) → suitable for larger threads or when special tools are unavailable.

Each method has its own advantages and limitations. The choice depends on the thread size, 材料, and machining conditions.

快速效果

Rapideffficed专注于高精度的CNC加工 18 多年的经验. 它的产品覆盖医疗, 通讯, 光学, 无人机, 智能机器人, automotive and office automation parts.

该公司的CNC加工中心包括四轴, five-axis and linkage machine tools, 并配备精密投影仪, 三坐标测量机, spectrometers and other precision testing equipment.

- 加工精度: up to 0.01mm

- 测试准确性: up to 0.001mm