1. 介绍

在现代制造格局中, CNC随着高速纺锤的转动已成为改变游戏规则的人. This advanced machining technique offers enhanced precision, 提高生产率, and superior surface finishes. Among the leading providers of such services is Rapidefficient, a name synonymous with excellence in the field of CNC machining. In this comprehensive article, we will delve into the intricacies of CNC turning with high-speed spindles and explore how Rapidefficient is leveraging this technology to meet the diverse needs of the industry.

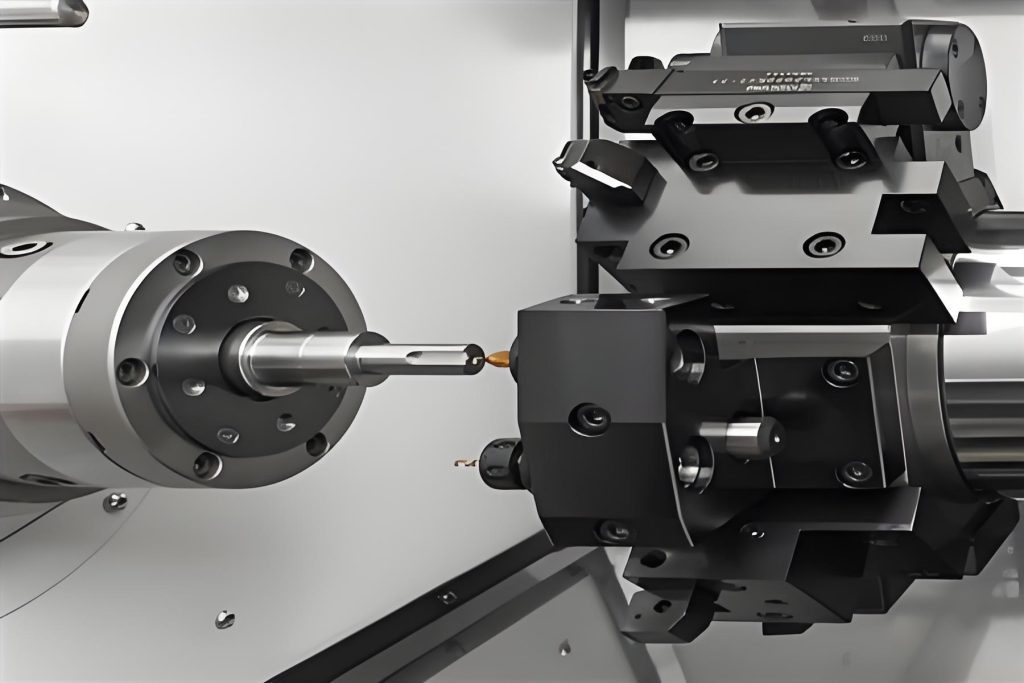

2. The Significance of High-Speed Spindles in CNC Turning

High-speed spindles are a crucial component in CNC turning operations. They enable the cutting tool to rotate at extremely high speeds, typically ranging from several thousand to tens of thousands of revolutions per minute (转速). This increased rotational speed offers several key advantages. 首先, it allows for faster material removal rates, significantly reducing the overall machining time. 例如, in the production of complex automotive components such as engine shafts or transmission parts, the use of high-speed spindles can cut down the manufacturing cycle by up to 30 – 50% compared to traditional spindle systems. 第二, high-speed spindles contribute to improved surface finish quality. The rapid rotation of the cutting tool results in a smoother cutting action, minimizing surface irregularities and reducing the need for additional finishing processes. This is of utmost importance in industries where aesthetics and functionality are equally critical, such as the aerospace and medical device manufacturing sectors.

3. Technical Capabilities of High-Speed Spindle CNC Turning

The technical capabilities of CNC turning with high-speed spindles are truly remarkable. These machines are equipped with advanced control systems that ensure precise and accurate positioning of the cutting tool. The high spindle speeds, combined with high feed rates, enable the machining of intricate geometries with minimal error. 例如, in the production of micro-components used in electronics or precision instruments, high-speed spindle CNC turning can achieve tolerances as tight as ± 0.005 毫米. 而且, the ability to work with a wide range of materials is another notable feature. Whether it’s hardened steels, exotic alloys, or lightweight aluminum and titanium, high-speed spindle CNC turning can handle them with ease. This versatility makes it a preferred choice for industries that deal with diverse material requirements.

4. Applications of CNC Turning with High-Speed Spindles

The applications of CNC turning with high-speed spindles span across numerous industries. 在汽车行业, it is used to manufacture critical components like pistons, valves, and crankshafts. The high precision and productivity offered by this technique help automotive manufacturers meet the increasing demand for high-quality and reliable vehicles. 在航空航天部门, components such as turbine blades, 起落架零件, and fuselage fittings are produced using high-speed spindle CNC turning. The ability to achieve complex shapes and tight tolerances is essential for ensuring the safety and performance of aircraft. 此外, 在医疗领域, 植入物, 手术器械, and prosthetics are fabricated with this technology. The smooth surface finishes and precise dimensions are crucial for the proper functioning and biocompatibility of these medical devices.

5. Rapidefficient’s CNC Machining Services

Rapidefficient offers a comprehensive range of CNC machining services with a particular focus on high-speed spindle CNC turning. The company houses state-of-the-art CNC machines equipped with high-speed spindles that can reach speeds of up to 30,000 转速. These machines are maintained and calibrated regularly to ensure optimal performance and accuracy. Rapidefficient’s team of highly skilled engineers and machinists possess extensive experience in working with high-speed spindle CNC turning. They are proficient in programming the machines to execute complex machining operations and can handle a wide variety of materials and component designs. The company also emphasizes strict quality control measures. Each component that undergoes high-speed spindle CNC turning at Rapidefficient is subject to multiple inspection points throughout the manufacturing process. This includes dimensional checks using advanced metrology equipment, surface finish analysis, and material property verification.

6. Quality Assurance at Rapidefficient

质量是Rapidefficy操作的基石. In the context of high-speed spindle CNC turning, the company follows a stringent quality assurance protocol. The raw materials used are sourced from reliable suppliers and are thoroughly inspected upon arrival. 在加工过程中, real-time monitoring systems are in place to detect any deviations from the set parameters. If any issues are identified, immediate corrective actions are taken to ensure that the final product meets the required quality standards. 加工后, a comprehensive final inspection is carried out. This involves detailed dimensional inspections using coordinate measuring machines (三坐标测量机), surface roughness measurements using profilometers, and visual inspections by trained quality control personnel. Only components that pass all these inspections are approved for delivery to the customers.

7. 定制化和灵活性

Rapidefficient understands that each customer has unique requirements. 所以, the company offers a high degree of customization and flexibility in its high-speed spindle CNC turning services. Whether it’s a one-off prototype or a large production run, Rapidefficient can tailor its manufacturing process accordingly. The company’s engineers work closely with the customers from the initial design phase to the final production. They provide valuable input and suggestions to optimize the component design for high-speed spindle CNC turning, ensuring both functionality and manufacturability. 例如, if a customer requires a specific surface finish or a particular geometric feature, Rapidefficient can adjust the machining parameters and tooling selection to achieve the desired result.

8. Competitive Advantage of Rapidefficient

Rapidefficient’s competitive advantage lies in its combination of advanced technology, 熟练的劳动力, 和以客户为中心的方法. The use of high-speed spindle CNC turning technology gives the company an edge in terms of productivity and quality. The experienced team of professionals ensures that the machining operations are carried out with the highest level of expertise and efficiency. 而且, Rapidefficient’s commitment to customer satisfaction sets it apart. The company offers fast turnaround times, competitive pricing, and excellent after-sales service. Customers can rely on Rapidefficient to not only deliver high-quality components but also to provide support and assistance throughout the entire product lifecycle.

9. 结论

综上所述, CNC turning with high-speed spindles is a revolutionary machining technique that offers numerous benefits in terms of precision, 生产率, 和质量. Rapidefficient has established itself as a leading provider of such services, with its state-of-the-art equipment, 熟练的劳动力, and comprehensive quality assurance and customization capabilities. Whether you are in the automotive, 航天, 医疗的, or any other industry that requires high-precision components, Rapidefficient is the ideal partner for your CNC machining needs. By choosing Rapidefficient, you can be assured of receiving top-notch products and services that will help you stay ahead in the highly competitive manufacturing landscape.