在广阔的制造业世界里, injection molding technology has become an important force in product molding and promoting industrial upgrading with its high efficiency, flexibility and low cost. The selection of injection molding materials is one of the key factors that determine product quality, performance and appearance. This article explores the diversity, characteristics and application of materials in manufacturing, and looks forward to how AI technology will bring new opportunities to the selection and optimization of injection molding materials.

一、注塑材料的多样性

注塑材料种类繁多,涵盖从热塑性塑料到热固性塑料的广泛范围。在,热塑性塑料,例如聚乙烯 (聚乙烯醇)、聚丙烯 (聚丙烯)、聚氯乙烯 (PVC)、ABS、尼龙 (PA), 等,因为它易于加工、可重复使用和可回收的特点,Dominant position in molding field。这些材料具有不同的物理和化学性质,比如硬度、韧性、耐热性、耐化学性, 等,为制造商提供丰富的选择。

二、注塑材料的特性及应用

The characteristics of materials directly determine the performance of products. 例如, ABS materials are widely used in automobiles, 电子产品, home appliances and other fields due to their good impact resistance, heat resistance and processing performance; nylon materials are the preferred materials for manufacturing mechanical parts such as gears and bearings due to their high strength, wear resistance and self-lubrication. 此外, with the enhancement of people’s environmental awareness, environmentally friendly materials such as bio-based plastics and degradable plastics are gradually favored by the market, bringing new development opportunities to the injection molding industry.

三、AI技术在注塑材料选择与优化中的应用

在AI技术的支持下, material selection and optimization have become smarter and more efficient. 通过大数据分析, AI can accurately predict the performance of different materials in different application scenarios and provide manufacturers with scientific material selection recommendations. 同时, AI can also automatically adjust injection molding process parameters according to product design requirements and production costs to maximize material utilization. 此外, AI technology can also be used in the design and optimization of injection molds to further improve production efficiency and product quality.

四、注塑材料的未来趋势

将来, it will develop towards a more environmentally friendly, high-performance and intelligent development. 一方面, with the enhancement of global environmental awareness, environmentally friendly materials such as bio-based plastics and degradable plastics will become the mainstream trend of the molding industry; 另一方面, in order to meet the market demand for high-performance products, new materials such as high-performance polymers and nanocomposites will continue to emerge. 同时, the widespread application of AI technology will promote the selection and optimization of materials to a new stage, providing strong support for the sustainable development of the manufacturing industry.

The selection and optimization of molding materials is a key link in the innovative development of the manufacturing industry. With a deep understanding of its diversity and characteristics, combined with the intelligent application of AI technology, manufacturing companies can more accurately select suitable materials and improve product quality and production efficiency.

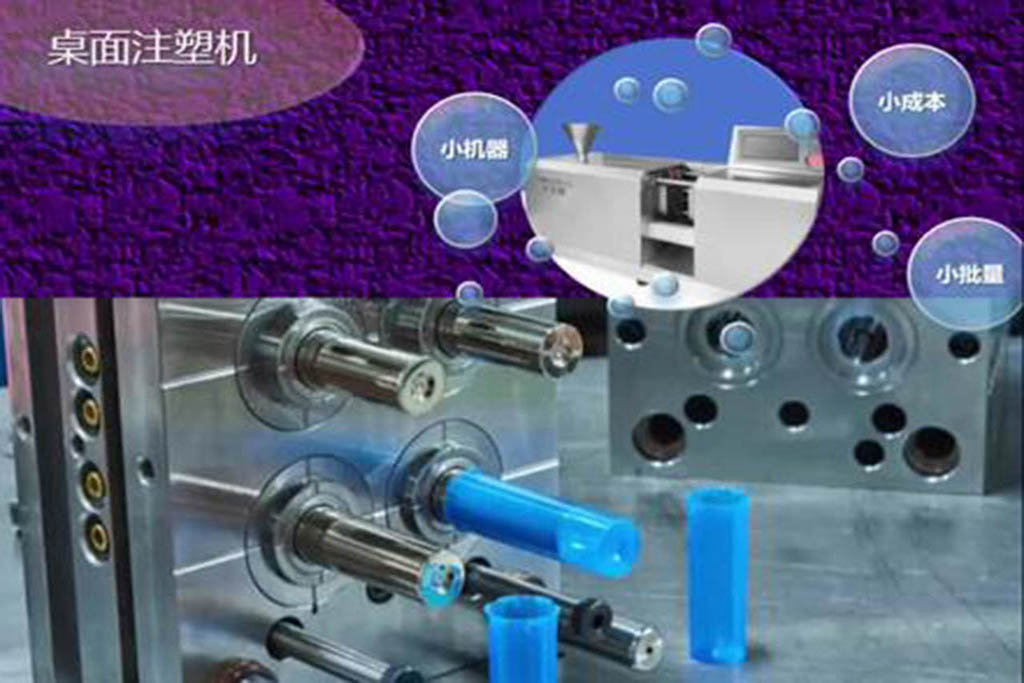

快速高效 is a leading provider of rapid prototyping and parts processing and manufacturing services,专注于塑料和金属零件的原型生产、定制加工和小批量生产,提供从样机到量产的一站式服务。

拥有先进的制造技术和高素质的团队,我们始终保持卓越的竞争优势。我们的制造服务满足您特定的产品设计需求,Including CNC加工、33D打印、硅胶模具真空注塑、快速成型和小批量注塑, 等。

我们的商业模式基于提供具有成本效益的解决方案,使客户在新产品开发的各个阶段都能受益。我们最自豪的社会价值是通过口碑增长获得来自世界各地客户的认可。,这些范围从独立发明家或设计师到大型工业、商业、医疗的、车、医疗及其他领域