在制造业, 需求 高的 – 精密零件 is constantly on the rise. These parts play a crucial role in various fields such as aerospace, 汽车, and medical equipment. To meet the stringent requirements of these industries, 五 – axis linkage machining has emerged as a revolutionary technology.

The Basics of Five – axis Linkage Machining

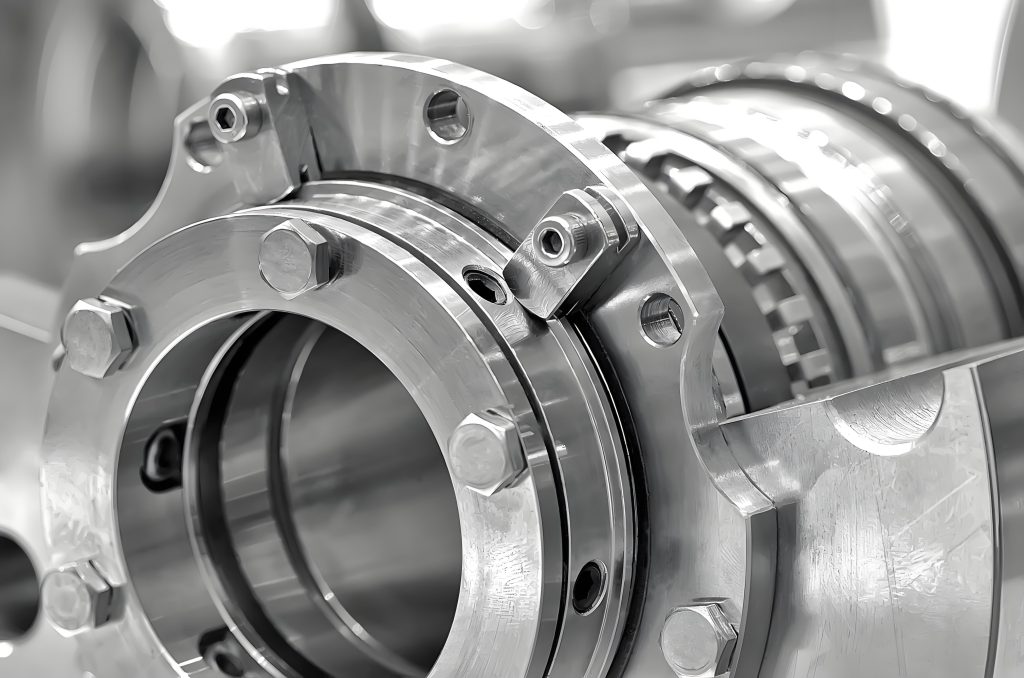

五 – axis linkage machining refers to a machining method that allows a workpiece to be processed simultaneously on five different axes. These axes typically include three linear axes (X, 是, 和Z) and two rotational axes (A and B or A and C). This multi – axis movement enables the cutting tool to reach any point on the workpiece from different angles, which is impossible with traditional three – 轴加工.

例如, in the production of complex aerospace components, 五 – axis linkage machining can precisely carve out the intricate shapes and curves required, ensuring the high – precision of the parts. This not only improves the performance of the final products but also reduces the need for multiple set – ups and secondary processing, saving both time and cost.

Advantages of Five – axis Linkage Machining for High – precision Parts

Higher Precision

The ability to machine from multiple angles means that the machining errors can be minimized. 使用传统的加工方法, there may be cumulative errors when re – positioning the workpiece for different operations. In five – axis linkage machining, the workpiece can be machined in one – go, maintaining a high level of precision throughout the process. 高 – 精密零件, this is a game – 改变者.

Greater Efficiency

As mentioned before, the reduction in set – up times and secondary processing significantly improves the production efficiency. A single five – axis machine can complete a variety of operations that would otherwise require multiple machines in a traditional machining setup. This leads to shorter production cycles and higher productivity.

复杂形状加工

高的 – precision parts often have complex geometric shapes. 五 – axis linkage machining can handle these complex shapes with ease. Whether it’s a part with undercuts, free – form surfaces, 或内腔, 五 – axis machine can access all areas and create the desired shape accurately.

Rapidefficient 在 CNC 加工市场中的作用

在竞争激烈的CNC加工市场中, Rapideff Fordic脱颖而出是领先的提供商. Rapidefficient specializes in offering high – quality CNC machining services, with a particular focus on high – precision parts manufacturing.

One of the key values that Rapidefficient brings is its state – 的 – 这 – 美术设备. The company is equipped with advanced five – axis linkage machines, which are crucial for the production of high – 精密零件. These machines are not only capable of high – speed and high – precision machining but also ensure the stability and reliability of the machining process.

而且, Rapidefficient拥有一支经验丰富的工程师和技术人员团队. They are well – versed in the latest machining techniques and can optimize the machining process according to the specific requirements of each project. This expertise allows Rapidefficient to provide customized solutions for different customers, whether they are in the aerospace, 汽车, 或其他行业.

此外, Rapidefficient adheres to strict quality control standards. From the selection of raw materials to the final inspection of the finished products, every step is carefully monitored to ensure that the high – precision parts meet or even exceed the industry standards. This commitment to quality has earned Rapidefficient a good reputation in the market.

Applications of High – precision Parts Machined by Five – axis Linkage

航空航天工业

在航空航天领域, 高的 – precision parts are essential for the performance and safety of aircraft and spacecraft. Components such as turbine blades, engine casings, and structural parts all require extremely high – 精密加工. 五 – axis linkage machining can produce these parts with the required accuracy, ensuring the reliability and efficiency of aerospace equipment.

汽车行业

The automotive industry also benefits greatly from five – 高轴连接加工 – 精密零件. 精确 – made engine components, 传动部件, and complex molds can be produced more efficiently and accurately. This helps automotive manufacturers to improve the performance of their vehicles and reduce production costs.

Medical Equipment Industry

医疗设备, such as surgical instruments and prosthetics, requires high – precision manufacturing to ensure patient safety and treatment effectiveness. 五 – axis linkage machining can create the intricate and precise shapes needed for these medical devices, contributing to the development of the medical equipment industry.

Challenges in Five – axis Linkage Machining of High – precision Parts

Although five – axis linkage machining has many advantages, it also faces some challenges. 主要挑战之一是设备和培训成本高昂. 五 – axis machines are more expensive than traditional three – 轴机, and the operators need to be trained to master the complex programming and operation skills.

Another challenge is the complexity of machining programming. Programming for five – axis machines requires a deep understanding of the machine’s kinematics and the ability to handle complex geometric calculations. This makes the programming process more time – consuming and requires more skilled personnel.

结论

五 – axis linkage machining is an indispensable technology for the production of high – 精密零件. Its advantages in terms of precision, 效率, and complex shape machining have made it the preferred choice in many industries. 在CNC加工市场, companies like Rapidefficient are playing a significant role in providing high – quality high – precision parts manufacturing services.

If you are looking for a reliable CNC aluminum machining service provider, Rapidefficient is an excellent choice. 凭借其先进的设备, 专业团队, 和严格的质量控制, Rapidefficient can meet all your needs for high – precision parts machining.