CNC加工是制造业中的主流技术. 由于其高效率和精度, many factories and companies use CNC machining to produce parts and products. 然而, calculating CNC machining costs can be challenging. Here’s a detailed look at how to calculate CNC machining costs and the factors that influence them:

1. Main Factors Determining CNC Machining Costs

1.1 材料成本

The materials used in CNC machining are a significant component of the cost. Consider the 类型, 质量, and quantity of material. Metals are generally more expensive and harder to machine than plastics, leading to higher machining costs.

1.2 Machine Time

Machine run time is a major cost factor. CNC machining requires setting correct 角度, speeds, and depths, which consumes time and labor. Longer machine operation increases costs.

1.3 Labor Costs

Labor costs include salaries, insurance, 和好处 for CNC operators and support staff. Complex projects requiring multiple workers will raise machining costs.

1.4 Design and Programming Costs

Before machining, products must be designed and programmed. These steps require specialized skills, so designer and programmer fees are included. Complexity of design and programming also affects cost.

2. Additional Factors Affecting CNC Machining Costs

2.1 Part Size and Shape

Larger parts require more machine time, 和 complex shapes increase design and programming costs.

2.2 Machine and Tool Condition

Poor machine or tool condition may reduce product quality or require more maintenance, increasing overall cost.

2.3 Volume Production

Producing multiple identical items can be more economical. Once setup is complete, cost per item decreases.

2.4 厚度, 精确, and Surface Finish

Tighter dimensional tolerances (例如。, ±0.01mm) or smoother surface finishes (例如。, Ra 0.8μm) require more precise equipment and additional quality control, raising costs.

2.5 Post-Processing and Finishing

Processes such as 阳极氧化, 电镀, 抛光, or coating add to total costs.

2.6 Geographic Location

Labor, electricity, and maintenance costs vary by region. CNC machining in Europe or North America is generally more expensive than in East Asia.

3. 概括

CNC machining costs are influenced by multiple factors, 包括:

- Material costs

- Machine time

- Labor costs

- 设计和编程

- Part size and shape

- Machine and tool condition

- Volume production

- Tolerance and surface finish

- Post-processing and finishing

- Geographic location

Carefully evaluating these factors ensures the most efficient and economical production costs.

4. 快速效果

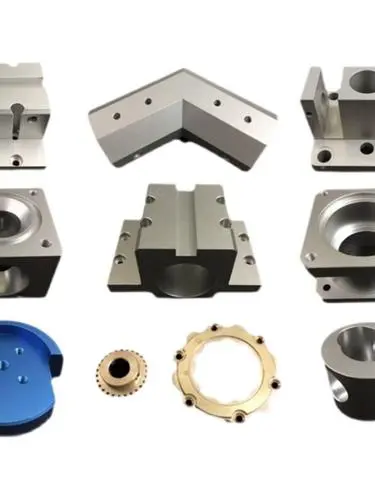

迅速的 specializes in high-precision CNC machining with 18 多年的经验. Its products cover:

- 医疗设备

- Communications devices

- Optical components

- Drones

- Intelligent robots

- Automotive parts

- Office automation parts

The company’s 数控加工中心 include four-axis, 五轴, 和连锁机床, and are equipped with:

- Precision projectors

- Three-coordinate measuring machines

- Spectrometers

- Other precision testing equipment

加工精度: 0.01毫米

测试准确性: 0.001毫米