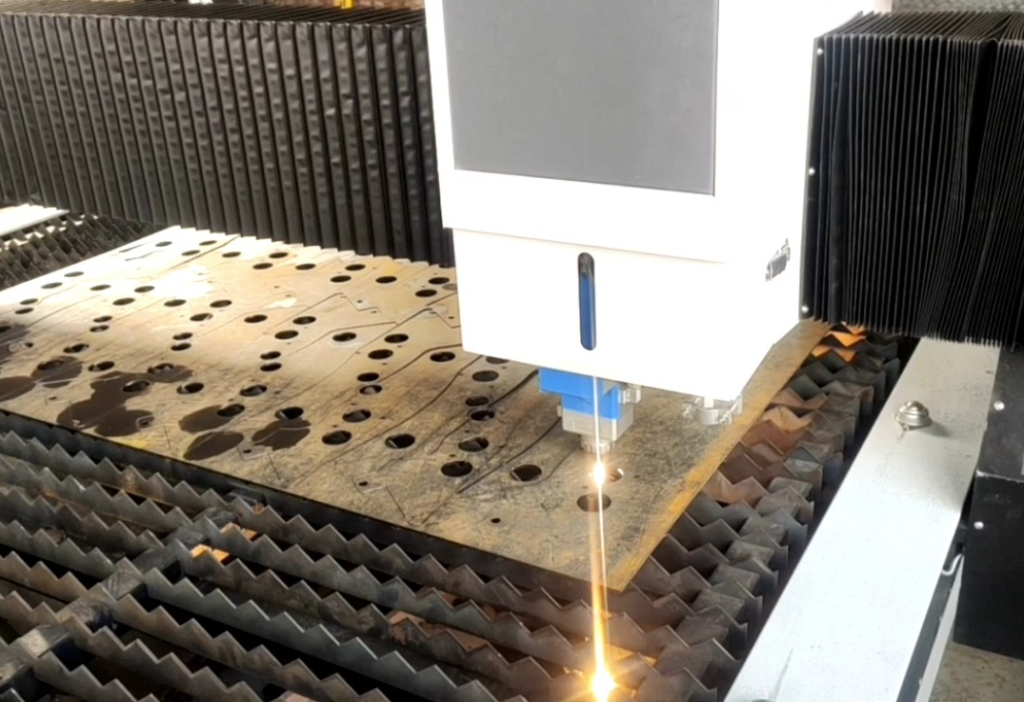

清晨, when engineer Xiao Wang uploaded a complex stainless steel part design drawing to the cloud system of the manufacturing service platform, he didn’t have to worry about the limitations of traditional machining. After a few hours, the precision-cut parts are ready to go, with mirror-smooth edges. Behind this, laser cutting technology is quietly reshaping the efficiency and boundaries of modern manufacturing services, becoming an invisible blade in industrial upgrading.

激光切割: 制造服务升级的无形刀片

清晨, when engineer Xiao Wang uploaded a complex stainless steel part design drawing to the cloud system of the manufacturing service platform, he didn’t have to worry about the limitations of traditional machining. After a few hours, the precision-cut parts are ready to go, with mirror-smooth edges. Behind this, laser cutting technology is quietly reshaping the efficiency and boundaries of modern manufacturing services, becoming an invisible blade in industrial upgrading.

制造服务: Transformation from OEM to Value Co-creation

Traditional manufacturing models are often limited to “incoming processing” and passively respond to demand. Modern manufacturing services have evolved into a deeply collaborative value network:

Solution-oriented: From simple part processing to providing full-process services covering design optimization, 材料选择, process verification, and fast delivery.

Flexible response core: 小批次, multiple varieties, and fast turnover have become the norm, and service providers need to have the ability to quickly adjust production lines.

Data-driven collaboration: Relying on the cloud platform, it realizes seamless transmission of design data, transparent visibility of production progress, and accurate access to demand forecasting.

激光切割: The Cornerstone of Manufacturing Services with Precision and Flexibility

In this service-oriented transformation, laser cutting technology has become a key technology that supports the core competitiveness of manufacturing services with its unique advantages:

Precision Leap: The high-energy laser beam focuses on diameters up to the micron level, making it easy to achieve precise machining of complex geometries and tiny holes (<0.1毫米), and the tolerance control far exceeds traditional methods, directly improving the quality and reliability of the final product.

Unbounded materials: From common carbon steel, 不锈钢, and aluminum, to copper, 黄铜, 钛合金, and even acrylic, 木头, fabric, and composite materials, one equipment can respond to changing needs and greatly expand the business coverage of manufacturing services.

Extreme flexibility: Digital drawing drive, switching product “zero” mold cost. After receiving the order, the software instantly analyzes the drawings and automatically generates the optimal cutting path to achieve agile production of “one piece order”, which perfectly meets the needs of small-batch customized services.

Efficiency Revolution: High-speed cutting (such as sheet cutting speeds of up to tens of meters/minute) combined with automated loading and unloading significantly reduces lead times. Platform-based operation can better integrate orders, optimize production scheduling, and maximize equipment utilization.

Practical picture of laser cutting empowering manufacturing services

Agile Prototyping and Proofing Services: Designers upload drawings, and the platform instantly generates quotations and arranges production, obtaining high-precision samples within 24-48 小时, accelerating product iteration cycles.

On-demand manufacturing of complex structural parts: Provide complex structural metal components that are difficult to reach by traditional processes for mechanical equipment, automated production lines, building curtain walls, 等, to meet the needs of lightweight and high-strength design.

Direct supply of personalized end products: Metal artworks, personalized signage, customized electronic equipment shells, 等, directly connect consumers and flexible production capacity.

Supply Chain Resilience Enhancement: Localized, distributed, and laser-cutting manufacturing service nodes reduce dependence on long-distance and high-volume supply chains, and quickly respond to regional demand fluctuations.

The Light of the Future: Intelligence and Deep Integration

The evolution of laser cutting in manufacturing services is far from stopped:

AI-Enabled Process Optimization: Machine learning based on historical data automatically recommends the best cutting parameters (power, 速度, gas) to adapt to new materials or complex graphics to improve yield and efficiency.

“One-click manufacturing” service closed-loop: The online platform integrates instant quotation, 直接制造 (design for manufacturing) analysis, automatic production scheduling, progress tracking, and logistics docking, and the user experience is extremely smooth.

Hybrid additive manufacturing: Combine technologies such as laser metal deposition (LMD) to achieve “cutting-additive repair/composite manufacturing” on the same platform, opening up a broader service space.

结语

激光切割, this invisible beam of light, has transcended the scope of a single processing technology. It is deeply embedded in the bones of modern manufacturing services and has become the core engine driving precise, 灵活的, efficient and intelligent services. In the wave of deep transformation of the manufacturing industry to service-oriented, personalized and networked, mastering and continuously upgrading laser cutting capabilities is the key to building future competitiveness for manufacturing service providers. When the intangible light dances precisely, tangible value is continuously created – this is the most vivid interpretation of manufacturing service upgrades.