市场对产品精度的要求越来越高. 追求极致精准, 五轴数控加工如何超越传统加工?

一. 传统加工方法的局限性

传统加工方法,如三轴数控机床,虽然在一定程度上满足了工业生产的需要,但当面对复杂曲面和高精度要求时,但又显得无能为力。刀具路径受限,难以到达工件的每个角落,导致加工效率低下,并且加工精度很难保证。这些限制限制了制造业的发展,制造高精度、复杂曲面加工成难题。

二. 五轴数控加工技术的兴起

1.多轴联动,扩大加工范围

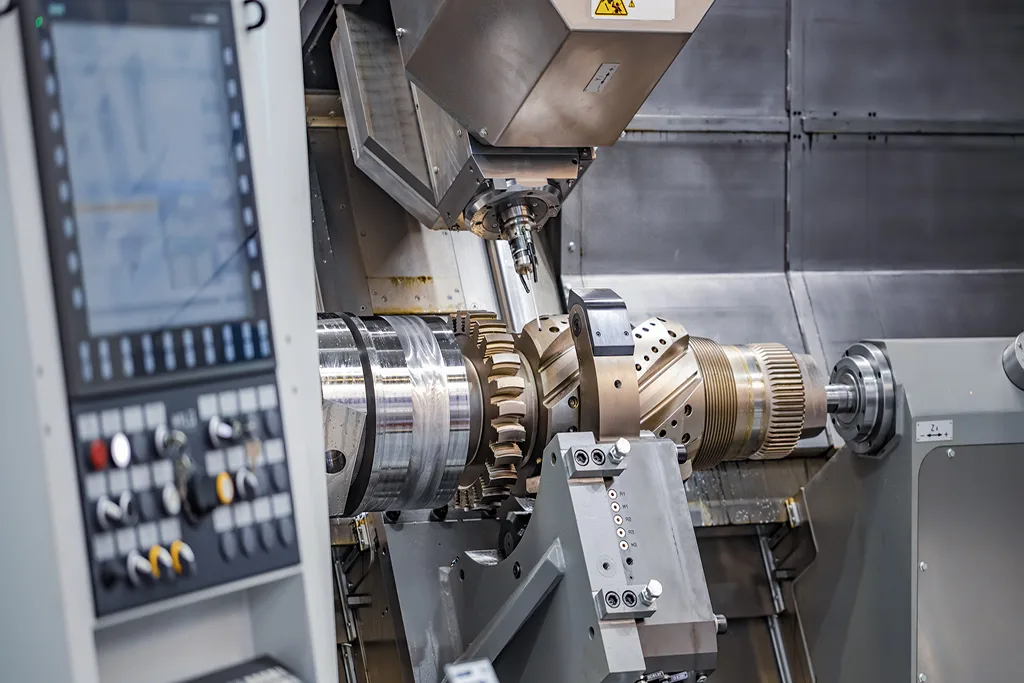

最大的特点是 五轴数控加工 技术就是它的多轴联动功能。在原来的X、是、Z基于三个直线运动轴,添加两个旋转轴 (通常是A、B轴或C轴),允许工具在三维空间中自由移动,实现复杂曲面的精密加工。这种多轴联动方式,大大扩展了加工范围,提高加工效率。

2.高效处理,提高生产效率

五轴数控加工技术优化刀具路径和切削参数,实现高效处理。一次装夹即可完成多面加工,减少重复夹紧次数,生产效率显着提高。同时,五轴机床的高速切削能力,进一步缩短加工周期,降低生产成本。

3.极高的精度,满足高要求

五轴数控加工技术及其高精度控制能力,满足市场对高精度产品的需求。五轴联动功能可以以极高的精度控制加工角度。,确保加工零件的精度。还,先进的控制系统和编程软件,使加工过程更加稳定、可靠的,进一步提高加工精度。

三、五轴数控加工在各领域的应用

航空航天五轴数控加工技术、汽车制造、模具制造等领域得到广泛应用。这些领域对产品的精度和复杂度要求极高,五轴数控加工技术以其卓越的性能,成功解决了这些问题,推动制造业发展。

读完这篇文章后, 您已了解五轴数控加工如何超越传统加工. 追求极致精准, 快速高效的高效, 准确可靠的加工能力成为众多企业的首选. Rapid Efficient不仅拥有强大的处理能力和灵活性, 同时还配备了先进的控制系统和编程软件,使操作更加简单、高效. 无论是加工复杂曲面还是实现高精度要求, Rapid Efficient可轻松应对,为公司创造更大价值.