斯普林斯: An Introduction

Springs are ubiquitous mechanical components that play a crucial role in modern life. They are elastic objects that can store and release mechanical energy, providing force and movement in a wide range of applications. From the simplest household items to complex industrial machinery, springs are essential for proper functioning and performance.

In the mechanical field, springs are widely used to control the movement of various parts. 例如, in engines, valve springs ensure the precise opening and closing of valves, allowing for efficient fuel combustion and power generation. In manufacturing equipment, springs are utilized to provide cushioning and shock absorption, protecting delicate components from excessive forces and vibrations.

The automotive industry heavily relies on springs for suspension systems. They help to smooth out the ride by absorbing bumps and unevenness on the road, enhancing both comfort and safety. Different types of springs, such as coil springs and leaf springs, are employed depending on the specific requirements of the vehicle.

在电子领域, 泉水 are found in numerous devices. They are used for electrical connections, ensuring reliable contact between components. Springs also play a role in switches and buttons, providing the necessary tactile feedback and facilitating smooth operation.

而且, springs are utilized in various other industries, 包括航空航天, 医疗的, 和消费品. 在航空航天应用中, they are used in landing gear systems and flight control mechanisms. In medical devices, springs are incorporated into instruments and implants to provide precise movement and support. In consumer products like toys, watches, and furniture, springs add functionality and enhance user experience.

Compression Springs

Compression springs are perhaps the most common type of spring. They are designed to resist compressive forces and are typically helical in shape. When a compression spring is subjected to an axial load, it compresses, storing potential energy. This energy is then released when the load is removed, causing the spring to return to its original length.

The working principle of a compression spring is based on Hooke’s Law, which states that the force exerted by a spring is proportional to its displacement. 换句话说, the more a compression spring is compressed, the greater the force it exerts in the opposite direction.

These springs find extensive use in various applications. 在汽车行业, they are used in suspension systems to absorb shocks and vibrations from the road, providing a smooth ride. They are also found in engine valves, where they help control the opening and closing of the valves, ensuring proper engine performance.

In the furniture industry, compression springs are used in mattresses and sofas to provide support and comfort. They distribute the weight evenly and return to their original shape when the load is removed, preventing sagging.

Another application is in industrial machinery, where they are used for vibration isolation, shock absorption, and as return springs in mechanical devices. 例如, in a stamping press, compression springs are used to return the punch to its original position after each stroke.

Extension Springs

Extension springs operate on the principle of stretching to store energy. When a force is applied to pull the spring, it elongates, and once the force is removed, it contracts back to its original shape. This ability to absorb and release energy makes them suitable for various applications.

One common application is in garage doors. The extension springs assist in counterbalancing the weight of the door, allowing it to be opened and closed smoothly. They provide the necessary tension to lift the door and keep it in the desired position. Without these springs, it would be extremely difficult to operate the garage door manually.

Another example is in balance scales. Extension springs are used to provide the restoring force that brings the scale back to its equilibrium position. When an object is placed on the scale, the spring stretches proportionally to the weight, and the scale indicates the measurement. This application requires precise calibration of the spring’s tension to ensure accurate readings.

Extension springs are also found in trampolines, where they are attached to the frame and the jumping mat. They provide the elasticity that allows the trampoline to bounce back when a person jumps on it, creating a fun and energetic activity. 此外, they are used in some exercise equipment, such as resistance bands, to provide the necessary resistance for strength training.

Torsion Springs

Torsion springs are helical springs that work by resisting and exerting torque. When a torsion spring is twisted around its axis, it stores potential energy, which is then released when the twisting force is removed, causing the spring to return to its original position.

The design of torsion springs allows them to provide rotational force and control the movement of objects. They are commonly used in applications where a specific amount of torque is required to rotate or hold a component in place.

在汽车行业, torsion springs are used in various components such as door hinges and trunk lids. They ensure smooth and controlled opening and closing of these parts, providing convenience and safety. In garage doors, torsion springs play a crucial role in counterbalancing the weight of the door, allowing it to be easily opened and closed manually or with the help of an opener.

Torsion springs are also found in many household items. 例如, in a mouse trap, the torsion spring provides the force needed to snap the trap shut when triggered. In some toys, such as wind-up toys, torsion springs are used to store energy and power the movement of the toy.

In industrial machinery, torsion springs are used in various mechanisms that require rotational force. They can be found in conveyor systems, where they control the tension of belts or chains. In printing presses, torsion springs are used to control the movement of rollers and ensure proper ink distribution.

Constant Force Springs

Constant force springs are a unique type of spring that can provide a nearly constant pulling force during stretching. They are usually made of stainless – steel strip coiled into a spiral shape. The diameter, force, and lifespan of the spring are determined by the stress applied during its production.

The operation of a constant – force spring is similar to stretching a ribbon. As the spring is stretched and recoiled, the working part is tangent to the spring’s own circle. As long as the diameter of the spring remains constant, the force it exerts is also constant. In extremely long spring designs, a changing diameter can have advantages. The pulling force increases slightly as the spring is stretched. 然而, this increase is relatively small compared to the length of the stretch and can be ignored in many applications.

Based on the application principle of constant – force springs, they can be divided into linear – motion constant – force springs and rotational – motion constant – torque springs. When linearly stretched, the force value is measured in units such as kilograms, newtons, or pounds. The characteristic of maintaining a constant force over a long stroke enables the functions of constant – force springs to be applied in products requiring linear motions such as the height adjustment of LED computer screens and fans, store display racks, or nail – gun pushing – nail devices for reciprocating, sliding, stretching, returning, balancing, or labor – saving operations.

When a constant – force spring provides rotational torque, the unit is inch – pounds (Newton – meters), 等. Constant – torque springs can be applied in automatic wire – winding, balancing weights, and power sources, such as automatic power – cord retraction, cordless curtains, clockwork – powered radios, and clockwork toys.

In some fields, the force of the constant – force spring needs to be variable. A spring with a decreasing force as it is stretched is a negative – slope (gradient) spring; a spring with an increasing force as it is stretched is a positive – slope spring. Constant – force springs also include both positive – slope and negative – slope springs. Cordless – curtain clockwork springs are one of the most common applications of negative – gradient – slope constant – force springs.

The application of constant – force springs in product design can save space and provide sufficient force for the product. 例如, 在汽车行业, constant – force springs are used in seat – belt retractors. The spring inside the retractor can ensure that the seat – belt is smoothly retracted and provides a constant tension, allowing the seat – belt to be adjusted freely according to the user’s needs while ensuring its reliable function.

In the field of home decoration, cordless curtains use constant – force springs. When you pull the curtain to a certain position, the constant – force spring can keep the curtain in that position without the need for additional ropes or complex locking mechanisms. This not only makes the operation of the curtain more convenient but also gives the overall appearance a more concise and beautiful look.

These examples show that the stability and reliability of constant – force springs play a crucial role in various applications. They can effectively meet the needs of different scenarios, providing users with a more stable and efficient experience.

Belleville Springs

Belleville springs, also known as disc springs, possess a unique conical or disc-like shape. This distinctive form enables them to endure substantial loads while undergoing relatively small deformations. When subjected to compressive forces, the Belleville spring exhibits a non-linear force-deflection characteristic, which is highly advantageous in specific applications.

In heavy machinery, Belleville springs are frequently employed as shock absorbers and vibration isolators. Their ability to absorb and dissipate energy under high loads helps protect the machinery from excessive vibrations and shocks, thereby enhancing its operational stability and lifespan. 例如, in large industrial presses and crushers, these springs can effectively reduce the impact forces generated during the working process, ensuring the smooth operation of the equipment and minimizing the risk of damage to critical components.

在航空航天领域, Belleville springs find crucial applications in various systems. They are used in aircraft landing gear mechanisms to provide reliable cushioning during touchdown, absorbing the significant impact forces and ensuring a smooth and safe landing. 此外, in spacecraft components, such as satellite deployment mechanisms, Belleville springs are utilized to precisely control the movement and positioning of parts, thanks to their high load-carrying capacity and stable performance in harsh space environments.

Another notable application of Belleville springs is in the field of automotive engineering. They are incorporated into clutch systems, where they play a vital role in transmitting torque and ensuring smooth engagement and disengagement of the clutch. The unique characteristics of Belleville springs allow for precise control of the clamping force, enhancing the overall performance and durability of the clutch assembly.

Spring Materials and Their Impact on Performance

The choice of spring material is a critical factor that significantly influences the performance and durability of springs. Different materials offer distinct properties, making them suitable for specific applications.

Carbon steel is a commonly used material for springs. It provides a good balance of strength and elasticity, making it suitable for a wide range of applications. 然而, carbon steel springs are prone to corrosion, especially in humid or corrosive environments. To enhance their corrosion resistance, carbon steel springs are often coated with materials such as zinc or nickel.

Stainless steel is another popular choice, particularly in applications where corrosion resistance is essential. Stainless steel springs offer excellent resistance to rust and oxidation, making them suitable for use in food processing, 医疗器械, and outdoor equipment. They are available in various grades, each with different levels of corrosion resistance and mechanical properties.

Alloy steels, which contain additional alloying elements such as chromium, vanadium, and nickel, are used when higher strength and durability are required. These alloys can improve the spring’s resistance to fatigue, 穿, and high temperatures. 例如, chrome-vanadium steel is known for its excellent strength and toughness, making it suitable for applications in automotive and industrial machinery.

In addition to metallic materials, non-metallic materials such as plastics and composites are also used in some spring applications. These materials offer advantages such as low weight, 耐腐蚀性, 和电绝缘. 然而, they generally have lower strength and stiffness compared to metallic springs.

When selecting a spring material, several factors need to be considered. These include the operating environment (温度, 湿度, corrosive substances), the required load and deflection characteristics, the desired lifespan of the spring, and cost considerations. 通过仔细评估这些因素, engineers and designers can choose the most appropriate spring material to ensure optimal performance and reliability in a given application.

The Significance of Springs in CNC Machining with Rapidefficient

在CNC加工领域, springs play a vital role, and Rapidefficient stands out for its excellence in this field. CNC machining demands high precision and reliability, and the right springs are essential to achieve optimal results.

Rapidefficient’s CNC machining services benefit greatly from the use of quality springs. 例如, in the machining of aluminum parts, which is a specialty of Rapidefficient, springs are used in various mechanisms. In the tooling system, springs provide the necessary force to hold the cutting tools firmly in place, ensuring accurate and stable machining. They also play a part in the clamping mechanisms, allowing for quick and efficient workpiece clamping and release.

The high-quality springs used by Rapidefficient offer precise force control. This is crucial in CNC machining as it helps to maintain the correct cutting pressure, resulting in better surface finishes and dimensional accuracy of the machined parts. Whether it’s a complex 3D contour or a simple drilling operation, the right spring force ensures that the machining process is smooth and consistent.

而且, springs contribute to the overall stability of the CNC machine. They absorb vibrations and shocks that occur during the machining process, preventing damage to the delicate components of the machine and reducing the risk of errors in the machined parts. This is especially important in high-speed machining operations where vibrations can have a significant impact on the quality of the finished product.

Rapidefficient’s expertise in spring selection and application, combined with its advanced CNC machining technology, enables it to deliver superior quality products to its customers. The company’s commitment to using top-notch springs in its machining processes is a testament to its dedication to providing high-precision and reliable manufacturing services. 无论是航空航天, 汽车, or electronics industries, Rapidefficient’s CNC machining capabilities, enhanced by the use of quality springs, ensure that customers receive parts that meet the strictest standards of quality and performance.

结论

Springs come in various types, 每个都有其独特的特征和应用. From the widely used compression and extension springs to the more specialized torsion, constant force, and Belleville springs, they all play essential roles in modern industry and daily life. The choice of spring type depends on factors such as the required force, deflection, 运行环境, and specific application needs.

在数控加工中, the quality and performance of springs are of utmost importance. 快速高效, as a leading CNC aluminum machining service provider, understands the significance of using high-quality springs in its operations. Their expertise in spring selection and application, combined with advanced machining technology, ensures the production of precise and reliable components for various industries.

Whether you are in the automotive, 航天, 电子产品, 或任何其他行业, choosing the right spring and partnering with a reliable machining service like Rapidefficient can make a significant difference in the performance and success of your products. If you are looking for top-notch CNC aluminum machining services, do not hesitate to contact Rapidefficient. Their team of experts will be happy to assist you in finding the best spring solutions and machining options to meet your specific requirements.

介绍

Springs are mechanical elements that can store and release energy through elastic deformation. They are widely used in various industries and play a crucial role in many applications. 在本文中, we will provide an overview of different types of springs and their applications. 此外, we’ll explore the value of Rapidefficient in the CNC machining market.

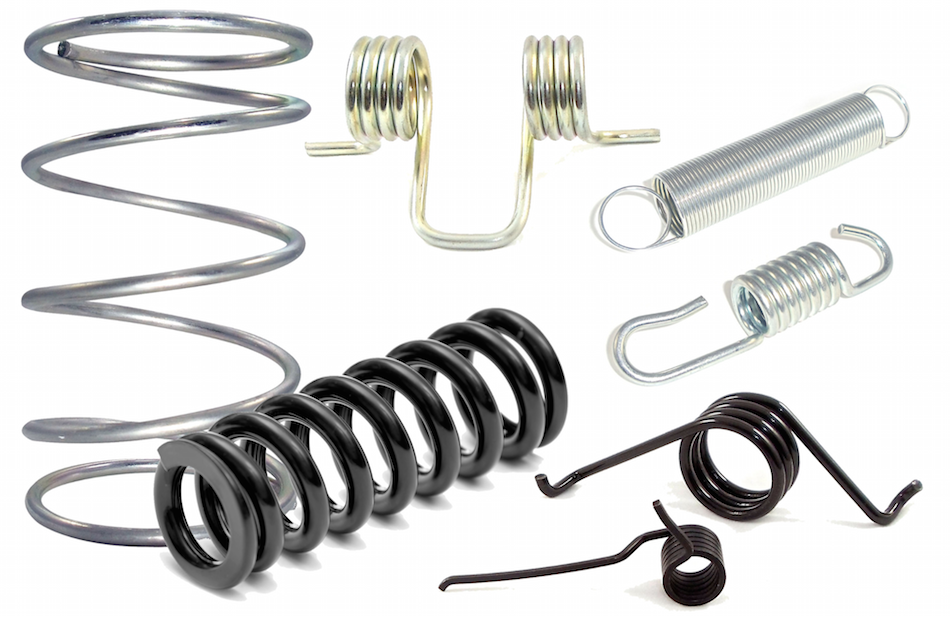

Types of Springs

- Compression Springs: These are helical springs designed to resist compressive forces. When a load is applied axially, they compress and store potential energy. Once the load is removed, they return to their original length. Compression springs are commonly used in automotive suspension systems, engine valves, 家具 (like mattresses and sofas), and industrial machinery for vibration isolation and as return springs.

- Extension Springs: Extension springs work by stretching to store energy. They elongate when a pulling force is applied and contract back when the force is removed. Applications include garage doors (to counterbalance the weight), balance scales, trampolines, and exercise equipment like resistance bands.

- Torsion Springs: Torsion springs are helical springs that resist and exert torque. When twisted around their axis, they store energy and return to their original position when the twisting force is removed. They are used in automotive components like door hinges and trunk lids, as well as in household items such as mouse traps and wind-up toys, and in industrial machinery for controlling rotational movement.

- Constant Force Springs: Made of coiled stainless-steel strip, these springs can provide a nearly constant pulling force during stretching. They are divided into linear-motion and rotational-motion types based on their application. They are used in products like LED computer screen height adjustment, cordless curtains, and seat-belt retractors.

- Belleville Springs: Also known as disc springs, they have a conical or disc-like shape and can endure large loads with relatively small deformations. They are used as shock absorbers and vibration isolators in heavy machinery, in aerospace landing gear and satellite deployment mechanisms, and in automotive clutch systems.

Applications of Springs

Springs have a vast range of applications across multiple industries:

- 汽车: From suspension systems to engine components, springs contribute to ride comfort, safety, and proper engine operation.

- 航天: They are crucial in landing gear, flight control mechanisms, and spacecraft components for withstanding high impacts and ensuring precise movements.

- 电子产品: Used in switches, 按钮, and for electrical connections to ensure reliable operation and tactile feedback.

- Furniture: Provide support and comfort in mattresses and sofas by distributing weight evenly.

- 工业机械: Aid in vibration isolation, shock absorption, and the operation of various mechanical devices.

The Role of Springs in CNC Machining with Rapidefficient

在数控加工中, precision and reliability are key. Springs play an important part in achieving optimal results:

- Tooling System: Springs hold cutting tools firmly in place, ensuring accurate and stable machining.

- Clamping Mechanisms: They allow for quick and efficient workpiece clamping and release.

- Force Control: High-quality springs used by Rapidefficient offer precise force control, maintaining the correct cutting pressure for better surface finishes and dimensional accuracy.

- Vibration Absorption: Springs absorb vibrations and shocks during machining, protecting the machine’s components and reducing errors in the machined parts.

Rapidefficient’s expertise in spring selection and application, combined with its advanced CNC machining technology, enables it to produce high-quality parts for various industries.

结论

Springs come in different types, 各有其特点和应用. Their proper selection is essential for the performance of various products and systems. 在数控加工中, the use of quality springs is vital, and Rapidefficient stands out in this regard. 如果您需要CNC铝加工服务, consider partnering with Rapidefficient. Their team can assist you in finding the best spring solutions and machining options to meet your specific requirements.