在现代制造的动态世界中, precision parts CNC machining has emerged as a cornerstone technology. It is the key to producing high – quality components that meet the exacting standards of various industries, 从航空航天到医疗设备. This article will delve into the intricacies of precision CNC machining, exploring how it ensures the creation of top – notch parts, and also highlight the significant value that rapidefficient brings to the CNC machining market.

The Importance of Precision in CNC Machining

Precision in CNC machining is not just a desirable trait; it is an absolute necessity. 在航空航天等行业, where components must withstand extreme conditions, the slightest deviation in a part’s dimensions can lead to catastrophic failures. 例如, turbine blades in aircraft engines need to be manufactured with micron – level precision to ensure efficient operation and safety. 在医疗领域, 精确 – made implants must fit perfectly within the human body to promote proper healing and functionality.

高的 – precision CNC machining also plays a crucial role in reducing production costs. When parts are machined accurately on the first attempt, there is less need for rework, which saves both time and materials. This efficiency not only benefits the manufacturer but also the end – users who can enjoy products with better quality and longer lifespan.

Key Factors Influencing Precision Parts CNC Machining

Advanced CNC Machinery

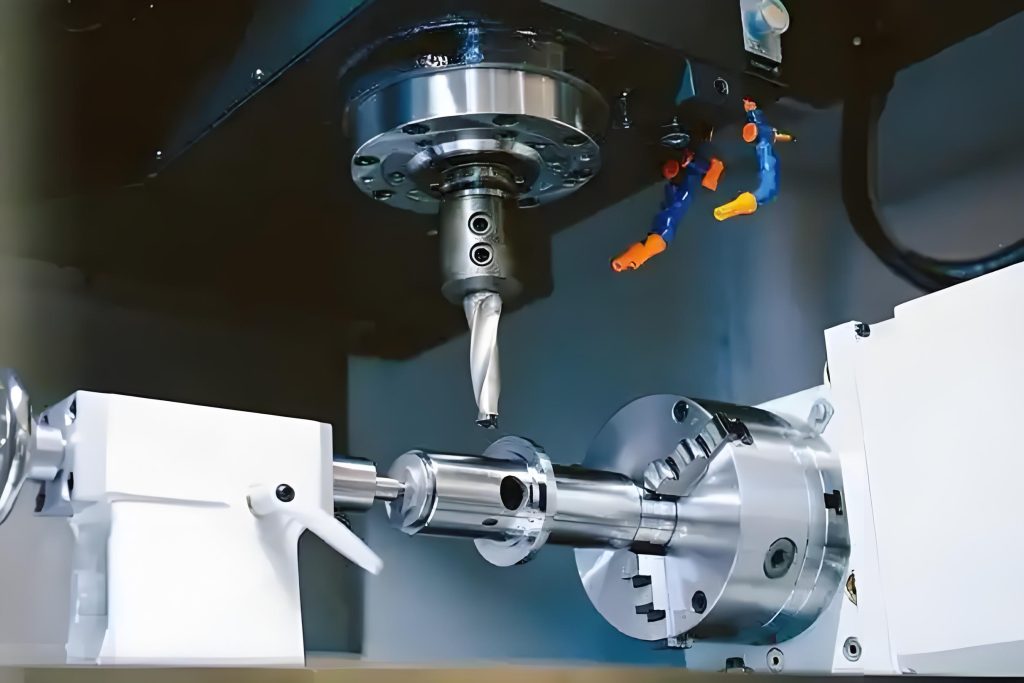

The quality of the CNC machine is fundamental to achieving precision. 高的 – end CNC machines are equipped with state – 的 – 这 – art components. 例如, linear motors provide smoother and more precise movement compared to traditional ball screws. These advanced machines also often feature high – resolution encoders that can accurately measure and control the position of the machine axes, ensuring that the cutting tools move precisely as programmed.

Precision Tooling

The choice of cutting tools is critical in precision CNC machining. Tools with superior geometry and high – quality materials are essential. Carbide – tipped tools, 例如, are known for their hardness and wear – resistance, making them ideal for machining tough materials with high precision. 此外, proper tool management, including accurate tool presetting and timely replacement, is vital. Dull or damaged tools can introduce errors and affect the surface finish and dimensional accuracy of the parts.

Sophisticated CAM Software

Computer – Aided Manufacturing (计算机辅助制造) software is the brain behind precision CNC machining. It generates the tool paths that the CNC machine follows. Advanced CAM software uses complex algorithms to optimize the tool paths based on various factors such as the material properties, 零件的形状, and the capabilities of the CNC machine. This optimization ensures that the machining process is not only accurate but also efficient, reducing cycle times and maximizing productivity.

Material Selection and Handling

The properties of the workpiece material significantly impact the machining process and the final precision of the parts. Different materials have different hardness, thermal expansion coefficients, and machinability. 例如, aluminum alloys are popular for their high strength – 到 – weight ratio and good machinability, but they also have a relatively high thermal expansion coefficient. 这意味着在加工过程中, temperature changes can cause the material to expand or contract, potentially affecting the dimensional accuracy of the part. 所以, proper material handling, such as pre – heating or cooling the material to a stable temperature before machining, is crucial.

Steps to Ensure High – Quality Precision Parts CNC Machining

Rigorous Machine Calibration

Regular calibration of the CNC machine is essential to maintain its precision. Calibration involves checking and adjusting the machine’s axes for straightness, parallelism, and positioning accuracy. Most modern CNC machines have built – in calibration systems, but it is important to follow the manufacturer’s recommended calibration schedule. By calibrating the machine regularly, any small deviations can be detected and corrected, ensuring that the machine continues to produce parts with the highest precision.

严格的质量控制

Implementing a comprehensive quality control system is crucial in precision parts CNC machining. This includes in – process inspection using advanced measuring tools such as coordinate measuring machines (三坐标测量机). CMMs can accurately measure the dimensions of the part during the machining process, allowing for immediate adjustments if any deviations are detected. Final inspection of the finished parts is also essential to ensure that they meet the required specifications.

Operator Training and Expertise

Well – trained operators are the backbone of precision CNC machining. Operators need to have a deep understanding of the CNC machine, the CAM software, and the materials being processed. They should be able to interpret the engineering drawings accurately and make informed decisions during the machining process. Regular training programs can keep operators updated on the latest machining techniques and best practices, enhancing their skills and knowledge.

The Value of rapidefficient in the CNC Machining Market

rapidefficient has established itself as a leading player in the CNC machining market for several reasons. 首先, their team of highly skilled engineers and technicians are experts in precision CNC machining. They have in – depth knowledge of the latest machining techniques and can handle complex projects with ease. Whether it’s producing intricate aerospace components or precise medical device parts, rapidefficient’s team has the expertise to deliver high – quality results.

第二, rapidefficient invests heavily in the latest CNC machining equipment and technology. This allows them to offer a wide range of precision machining services, from milling and turning to grinding and EDM (电气加工). Their advanced equipment, combined with their technical expertise, enables them to meet the most stringent requirements of their clients.

而且, rapidefficient places a strong emphasis on efficiency without compromising on quality. Their streamlined production processes and advanced management systems ensure that projects are completed in a timely manner. This is especially important in industries where time – 到 – market is critical. By providing high – quality parts quickly, rapidefficient adds significant value to their customers’ businesses.

结论

Precision parts CNC machining is a complex and demanding process that requires a combination of advanced technology, skilled operators, 和严格的质量控制. By paying attention to factors such as machine quality, 工装, CAM software, 和物料搬运, manufacturers can produce high – quality parts that meet the needs of various industries. When it comes to finding a reliable partner for precision CNC machining, 特别是铝制零件, rapidefficient stands out as an excellent choice. 他们的专业知识, 先进设备, and commitment to efficiency make them a top – tier option in the market.