在半导体制造的高科技世界中, 精度就是一切. 每个组件, 从最小的晶圆到最大的加工机器, 必须以最高精度制造,以确保可靠性和性能. 这是哪里 半导体轴承零件 发挥着至关重要的作用. 这些元件对于维持半导体制造设备的稳定性和精度至关重要, 它们的生产需要专门的精密加工厂.

半导体轴承精度的重要性

半导体制造涉及光刻等高度敏感的工艺, 化学气相沉积, 和离子注入. 这些过程需要机器以极高的精度和稳定性运行. 在这种情况下,轴承必须能够承受高速, 保持准确性, 并抵抗刺激性化学品的腐蚀. NYZ 和 Schatz 等公司专门生产满足这些严格要求的薄壁轴承和其他精密部件.

半导体轴承的主要特点

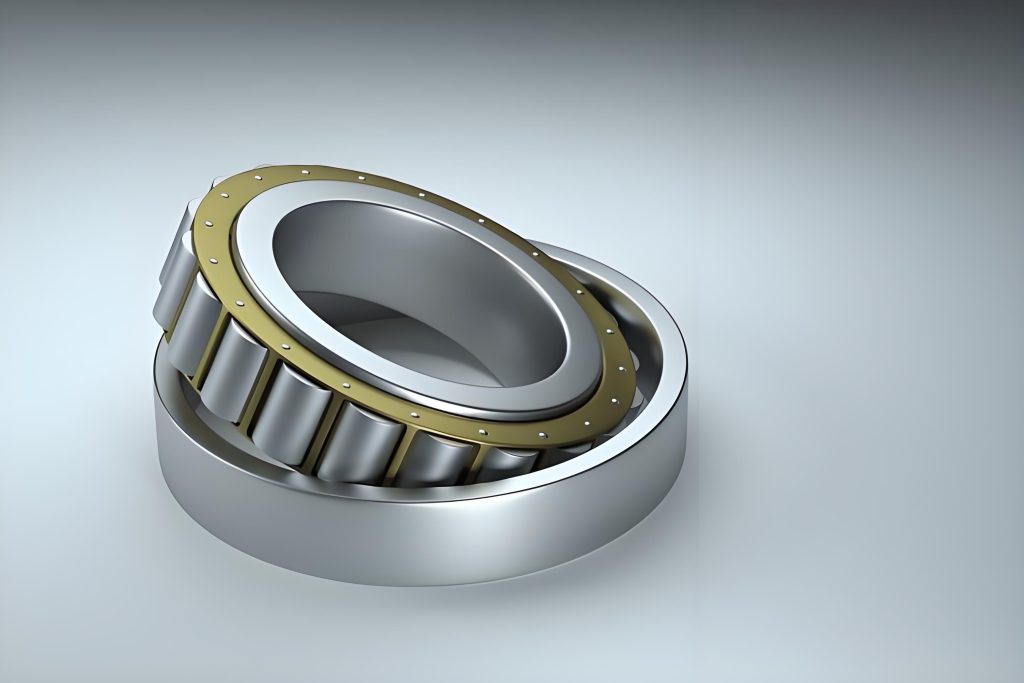

用于半导体应用的精密轴承通常具有:

高精度运行精度,确保性能一致.

耐腐蚀材料和精密密封件可保持清洁度和可靠性.

可定制设计以满足特定设备需求, 包括薄片, 角接触, 和混合陶瓷轴承.

精密加工技术

半导体轴承零件的生产涉及多种先进的数控加工技术:

数控铣削和车削: 这些工艺允许创建复杂的几何形状和严格的公差, 对于高精度轴承至关重要.

电气加工 (电火花加工): 该技术用于创建复杂的形状并在硬质材料中实现高精度.

线切割: 非常适合生产高精度的薄型复杂零件.

精密加工的挑战与解决方案

生产半导体轴承零件面临多项挑战, 包括对高精度的需求, 复杂的几何形状, 以及先进材料的整合. 解决方案包括:

投资于细致的夹具设计以确保安全的工件固定.

利用先进的测量设备实施全面的质量控制计划.

利用模块化夹具和先进的工件夹具解决方案实现多功能性.

CNC加工中RAPIDEFF的价值

在竞争激烈的数控加工市场中, 迅速的 作为为CNC铝处理提供快速有效的解决方案的领导者而引人注目. 他们在精确加工方面的专业知识可确保客户在周转时间快速获得高质量的零件. 无论您需要半导体设备的定制组件还是其他高科技应用的复杂零件, Rapidefffice具有满足您需求的技术和专业知识.

结论

精密加工是半导体轴承零件生产的关键工序, 确保这些组件满足半导体制造所需的高标准. 先进的技术和专业的工具使制造商能够克服生产复杂零件的挑战. 像Rapidefffice这样的公司处于这一趋势的最前沿, 提供可靠、高效的解决方案,以满足现代半导体行业的需求.

关于Rapidefficient

Rapidefficient是数控加工服务的领先提供商, 专注于铝材及其他精密零部件. 他们对质量和效率的承诺使他们成为寻求可靠制造解决方案的公司的值得信赖的合作伙伴. 无论您需要自定义组件还是大规模生产, Rapideff提供的高质量零件以及快速周转时间.